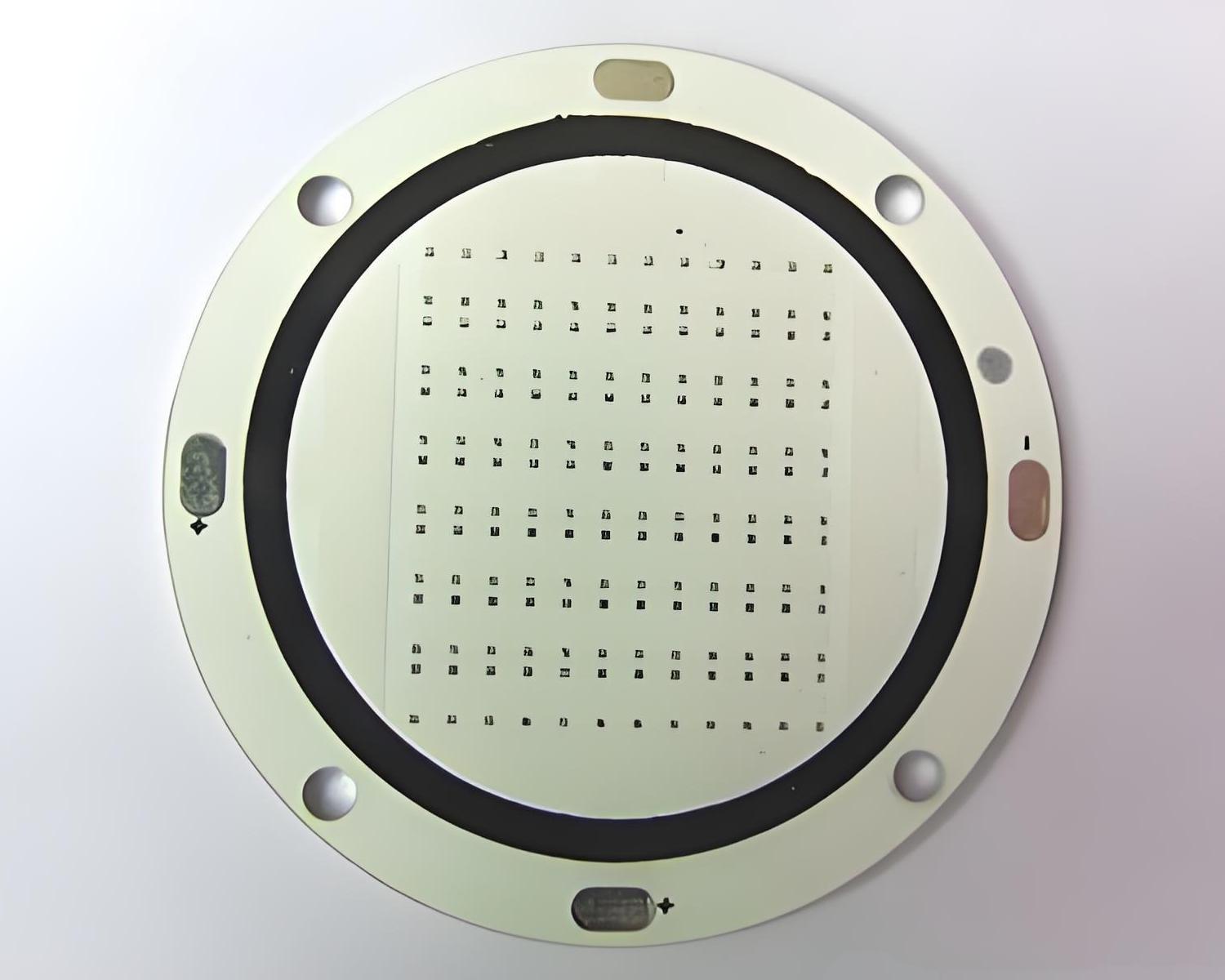

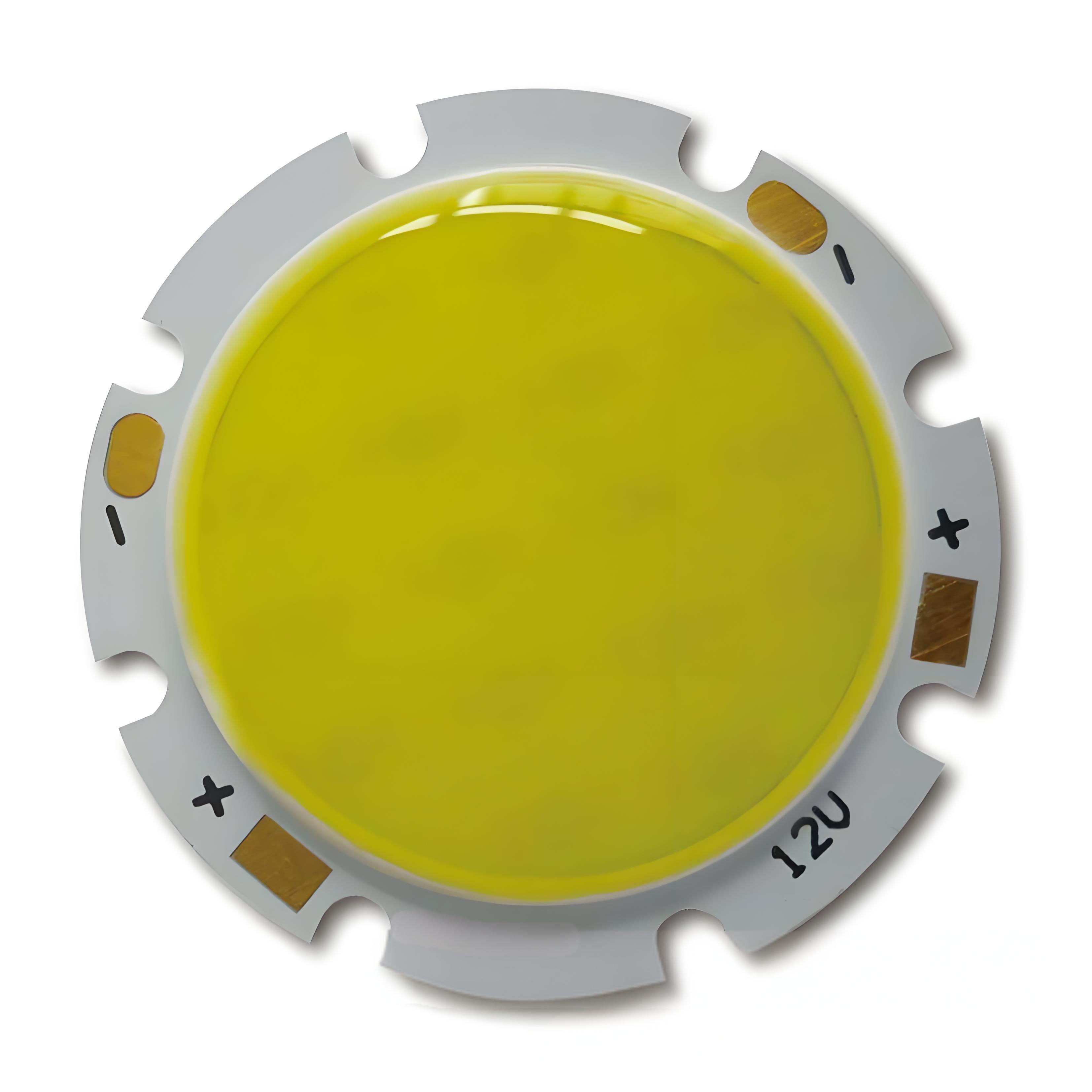

COB immersion gold aluminum substrate is a high-power packaging solution that directly bonds the LED chip (Chip On Board) to an aluminum substrate treated with immersion gold.

The aluminum substrate quickly dissipates heat, while the immersion gold layer ensures long-term oxidation resistance of the chip pads, ensuring reliable soldering. This eliminates the need for brackets and reflow soldering, resulting in higher luminous efficacy and longer lifespan. It has become a core substrate for high-power LED modules.

Do you have any questions about COB aluminum PCBs?

- Does the immersion gold coating and thermal conductivity meet COB heat dissipation requirements?

- Do the dimensions and specifications match COB packaging and lighting fixture installation?

- Can the immersion gold process and materials withstand long-term high-temperature use?

- Do the performance and cost meet expected price/performance ratios?

BEST Technology’s COB aluminum substrates can answer your questions.

- The immersion gold layer reduces contact thermal resistance, while the aluminum base and highly thermally conductive insulation layer quickly dissipate concentrated heat from the COB, ensuring efficient heat dissipation.

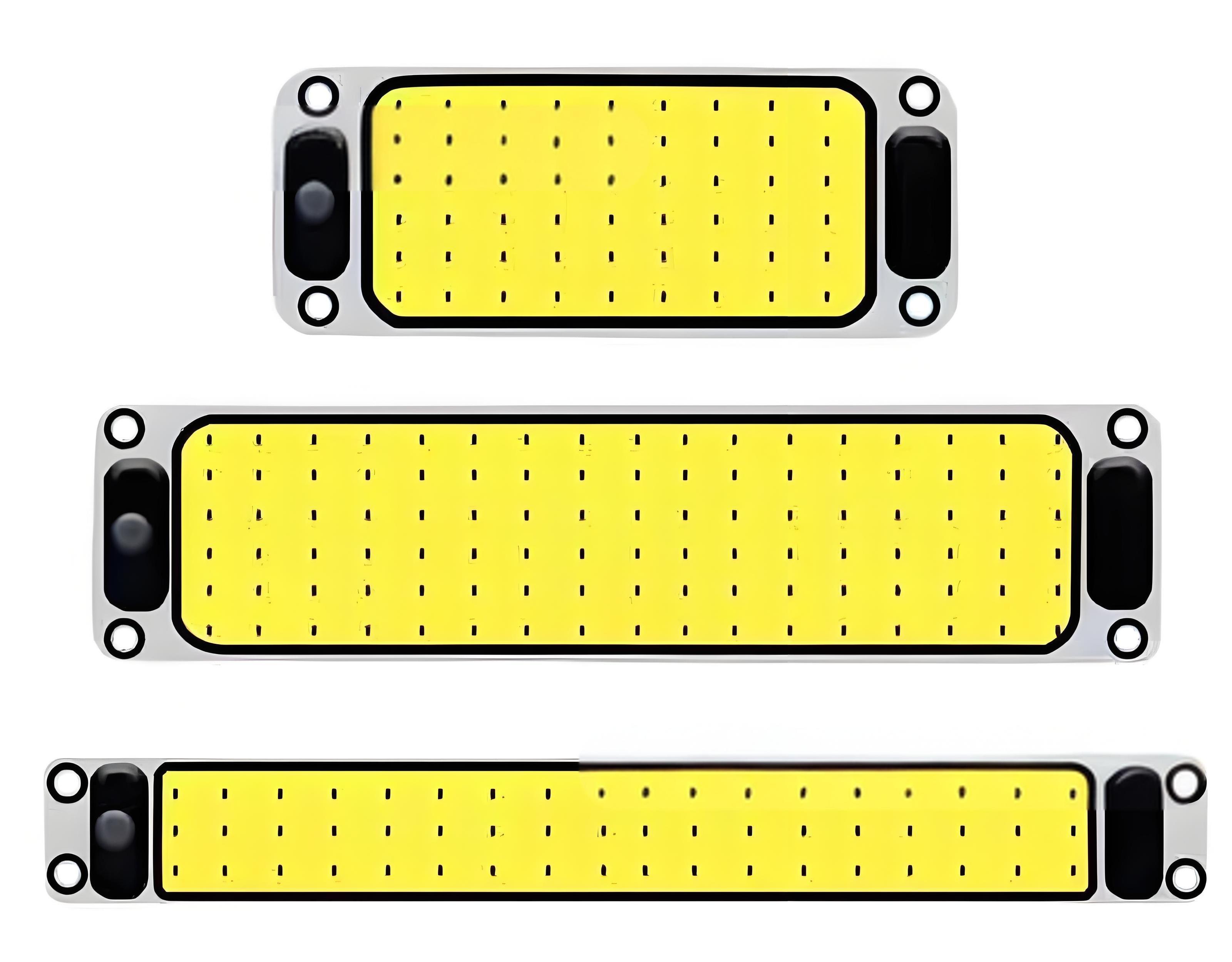

- The COB package area size and overall shape can be customized to accommodate different power COBs and lamp mounting structures.

- The immersion gold layer offers strong oxidation resistance, and the substrate has undergone high-temperature cycling testing without delamination, ensuring it can withstand the long-term high-temperature operating environment of the COB.

- High heat dissipation ensures COB lifespan, while customized processing optimizes costs, resulting in a reasonable balance of performance and price.

What is COB aluminum substrate?

COB aluminum substrate is a type of PCB that directly mounts LED chips on an aluminum base. Unlike traditional PCBs that use fiberglass, aluminum substrates use metal for better heat dissipation. This structure ensures LEDs operate efficiently and last longer.

The core of a COB aluminum substrate consists of three layers:

- A copper circuit layer for electrical connections.

- A dielectric layer for insulation and heat transfer.

- An aluminum base layer for mechanical support and thermal conduction.

This design keeps LEDs cool and improves performance. Itâs the reason COB substrates are widely used in LED lighting, automotive lights, and high-power applications.

Is immersion gold the same as ENIG?

Yes and no. Immersion gold is a key step in the ENIG (Electroless Nickel Immersion Gold) process. ENIG has two layers: a nickel layer and a thin gold layer. Nickel acts as a barrier to protect the copper, and gold prevents oxidation and ensures good solderability.

Therefore, immersion gold usually refers to the gold layer applied in the ENIG process. This finish is popular because it provides excellent corrosion resistance and long shelf life.

Can you plate aluminum substrate with gold?

Yes, you can. In fact, plating aluminum substrates with gold is common in high-end electronic applications. However, the process is not as simple as plating copper. Aluminum forms an oxide layer quickly, which must be removed before plating.

To apply immersion gold on an aluminum substrate, BEST Technology first coat the aluminum with a conductive layer, usually copper. Then, they apply the ENIG finish on top. This method ensures strong adhesion and reliable performance.

What are the benefits of immersion gold on aluminum substrates?

The benefits are impressive. Here are the main reasons why immersion gold is chosen for COB aluminum substrates:

- Superior Corrosion Resistance: Gold does not tarnish or oxidize, so it protects the surface even in harsh environments.

- Excellent Solderability: The gold layer makes soldering easier and more reliable, especially for fine-pitch components.

- Improved Electrical Performance: Gold has low contact resistance, which enhances signal integrity.

- Long Shelf Life: Boards with immersion gold can be stored longer without losing quality.

- High Reliability for LED Applications: COB LEDs generate heat, and gold plating helps maintain stable performance under thermal stress.

These benefits make immersion gold plating a preferred choice for high-end LED lighting, automotive electronics, and industrial controls.

How thick is gold in ENIG finish?

The gold layer in an ENIG finish is very thin, but itâs enough to provide excellent protection. Typically, the thickness ranges from 0.05 to 0.1 microns. This thin layer ensures good solderability without adding significant cost.

The nickel layer beneath the gold is thicker, usually around 3 to 6 microns. Together, these layers create a strong barrier that protects the copper from oxidation and maintains good electrical conductivity.

Is ENIG better than HASL?

For high-end applications like COB aluminum substrates, ENIG is better than HASL (Hot Air Solder Leveling). Hereâs why:

- Flat Surface: ENIG provides a smooth, flat surface, which is essential for small components and fine-pitch designs.

- Better Corrosion Protection: Gold offers superior resistance to oxidation compared to HASL.

- Higher Reliability: ENIG is more stable for thermal cycling and high-power devices.

HASL is cheaper and works well for simple boards, but for COB LEDs, ENIG is the clear winner.

What are the problems with ENIG solderability?

ENIG is reliable, but there are some challenges:

- Black Pad Issue: If the plating process is not controlled, it can lead to corrosion of the nickel layer, causing poor solder joints.

- Higher Cost: ENIG is more expensive than HASL or OSP finishes.

However, these issues rarely occur when working with BEST Technology, a trusted PCB manufacturer that follows strict quality controls.

What are the uses of COB aluminum substrate?

COB aluminum substrates are used in a wide range of applications:

- LED Lighting: High-brightness LEDs for residential, commercial, and industrial lighting.

- Automotive Lights: Headlights, tail lights, and daytime running lights.

- Display Backlighting: LCD and signage displays that need uniform light.

- Medical Equipment: Devices that require precise lighting and heat management.

- Industrial Control Systems: Where stable performance and long life are critical.

These uses show how important COB immersion gold aluminum substrates are in modern technology.

Conclusion:

COB aluminum substrates provide excellent heat dissipation and mechanical strength for LED applications. When paired with immersion gold plating, they offer even greater reliability, corrosion resistance, and solderability. ENIG is better than HASL for high-end boards, and the gold layer, though thin, ensures long-lasting performance.

If you need high-quality COB immersion gold aluminum substrates, contact us today at sales@bestpcbs.com

Tags: COB immersion gold aluminum substrate, gold immersion plating, immersion copper plating, immersion gold on copper, silver immersion plating