Why choose aluminum PCB sheet for battery management system? Let’s explore thermal solution, design guide and case study for aluminum PCB sheet.

Are you troubled with these issues?

- Is your BMS module temperature out of control?

- Is the BMS aluminum PCB heat dissipation solution expensive?

- Do aluminum PCB have poor reliability in high-humidity environments?

EBest Circuit (Best Technology) can provide services + solutions:

- Customized Thermal Design: Using aluminum substrates instead of heat sinks, heat is directly dissipated from the chip, achieving a measured temperature reduction of 35%, saving BMS layout space. (Thermal resistance between the metal substrate and power devices is <0.5Ā°C/W).

- Low-Cost, Highly Integrated Solutions: We offer single layer or double layer aluminum based PCBs with integrated sampling circuits and heat dissipation, reducing the procurement cost of heat dissipation components and BOM costs by 18%. (Aluminum PCB replace heat sinks, thermal grease, and mounting brackets.)

- Corrosion-Resistant Treatment: Anodizing and conformal coating (1000 hours salt spray test) ensures compatibility with extreme environments ranging from -40Ā°C to 150Ā°C, with an insulation withstand voltage of ā„3kV. (The aluminum PCB’s surface oxide layer isolates moisture and salt spray.)

Welcome to contact us if you have any request for aluminum PCB: sales@bestpcbs.com.

Why Choose Aluminum PCB Sheet for Battery Management System?

Aluminum PCB sheet are chosen for battery management systems (BMS) for the following reasons:

Efficient Thermal Management Capabilities

- The aluminum substrate boasts a thermal conductivity of 160-200 W/mĀ·K, over 500 times that of FR4. This rapidly dissipates Joule heat generated during battery charging and discharging, preventing local cell temperatures from exceeding the safety threshold of 60Ā°C and significantly reducing the risk of thermal runaway.

Balanced Lightweight and Structural Strength

- Aluminum’s density is only one-third that of FR4, reducing the weight of the BMS module while maintaining a flexural strength of 150 MPa sufficient to withstand vehicle vibration, meeting the lightweight and seismic design requirements of electric vehicles.

Electrical Insulation Reliability

- A ceramic-filled epoxy insulation layer (breakdown voltage >2 kV) effectively isolates the circuitry from the metal substrate in high-voltage battery packs (such as the 800V platform), keeping leakage current below the Ī¼A level.

Compatible Thermal Expansion

- Aluminum’s thermal expansion coefficient (24 ppm/Ā°C) is close to that of copper foil (17 ppm/Ā°C), reducing the risk of solder joint cracking during charge and discharge cycles and improving BMS reliability in extreme temperatures ranging from -40Ā°C to 125Ā°C.

Passive Cooling Integrated Design

- The aluminum substrate acts as a direct heat sink, eliminating the need for additional heat sinks and reducing the BMS module thickness by 30%, making it suitable for space-constrained battery pack layouts.

Cost-Effectiveness

- While the cost per board is 20% higher than FR4, the reduction in heat dissipation components and the extension of battery life (increasing cycle life by over 15%) reduce the overall lifecycle cost by approximately 12%.

Environmental Compliance

- The aluminum is 100% recyclable, and its production energy consumption is 40% lower than traditional PCBs, meeting the sustainability requirements of the EU’s new battery regulation (mandating a 90% recycling rate by 2027).

Applications of Aluminum PCB Sheet in BMS

- Battery Module Acquisition Board: Integrated temperature and voltage acquisition chips adapt to the compact structure of soft-pack/cylindrical batteries.

- High-Voltage Main Control Board: Carries the main control MCU and isolated communication chip.

- Balancing Board: Layouts active balancing MOSFETs/inductors.

- Wireless BMS Communication Module: Integrated Bluetooth/Wi-Fi chips.

- Fast Charge Interface Protection Board: Carries the high-voltage connector and fuse.

- Thermal Management Control Unit: Integrated with an NTC temperature sensor interface.

Aluminum PCB Heat Dissipation Solution for BMS

Customizing heat dissipation paths by functional module

- Based on the heat dissipation differences among modules within the BMS, such as the acquisition board, main control board, and balancing circuit, the copper layer thickness and routing layout of the aluminum substrate are adjusted.

- For example, the high-voltage main control board of a leading automaker utilizes a 4oz thick copper layer, combined with a localized gold plating process, to reduce the temperature rise in high-current paths by 30%, maintaining a stable temperature of core components below 65Ā°C.

Embedding thermally conductive materials to fill gaps

- Introducing low-resistance thermal pads or phase-change materials between the aluminum substrate and the battery module or heat sink casing reduces the contact thermal resistance to below 0.5Ā°CĀ·cmĀ²/W.

- Using this solution, a new energy brand reduced the BMS failure rate from 15% to 1% in a -40Ā°C to 125Ā°C cycle test, extending its service life by two years.

Enhanced heat dissipation with micro-heat pipes/vapor chambers

- For high-power density scenarios, such as fast-charging ports, heat pipes or vapor chambers (VCs) are embedded within the aluminum substrate to quickly diffuse local hot spots.

- During actual testing at 100kW fast charging, this solution reduced temperature variations by 75%, preventing protection plate failure due to local overheating.

Simulation Optimization Reduces Trial-and-Error Costs

- Using FloTHERM or Icepak thermal simulation software, fluid-thermal coupling analysis of the aluminum substrate layout was performed.

- After adjusting the copper foil distribution, a Tier 1 supplier increased the prototype vibration test pass rate from 85% to 99%, reducing secondary development costs by 40%.

Balancing Lightweight and Cost

- A 1.5mm-2.0mm thick 5052 aluminum-magnesium alloy substrate was used, achieving a balance between rigidity and weight.

- Compared to copper substrates, this solution achieves a 40% weight reduction and a 25% cost reduction, while also passing automotive-grade vibration and salt spray tests (ISO 16750/ASTM B117).

BMS Aluminum PCB Sheet Design Guide

Below are BMS aluminum PCB sheet design guideline:

1. Layer Stackup Optimization

- Use a three-layer structure: circuit layer (35Ī¼mā280Ī¼m copper foil), insulation layer (0.1mmā0.3mm epoxy with ā„0.8W/mĀ·K thermal conductivity), and metal base (1.0mmā2.0mm aluminum).

- Validate via thermal simulation (e.g., FloTHERM) to refine copper distribution and reduce temperature variation by up to 75% in high-temperature environments.

2. Trace Routing for Thermal and EMC Compliance

- Place high-current devices (e.g., MOSFETs) near substrate edges for efficient heat dissipation. Use āwide-narrow-wideā traces to minimize hotspots.

- Maintain ā„2mm clearance between critical signals (CAN buses) and high-current paths. Add shielding or ferrite beads to suppress noise.

3. Thermal Integration Solutions

- Embed micro heat pipes or vapor chambers (VCs) to spread localized heat. Pair with low-thermal-resistance pads (ā¤0.5āĀ·cmĀ²/W) for gap filling.

- For high-power modules (e.g., DC converters), use liquid-cooled substrates with 2mm-thick, 3W/mĀ·K thermal pads to limit temperature rise to ā¤20ā.

4. Mechanical Fixation and Surface Treatment

- Secure PCBs with bolts spaced ā¤50mm apart. Add edge positioning holes to prevent assembly misalignment.

- Apply ENIG (ā„5Ī¼m thickness) to enhance solderability and corrosion resistance, extending salt spray resistance to 168 hours (ASTM B117).

5. Multi-Dimensional Testing Protocols

- Thermal: Monitor key component rises (e.g., ā¤15ā at 85ā/72hr). Conduct thermal shock (-40ā~125ā/100 cycles) with deformation ā¤0.1mm.

- Electrical: Validate voltage/current accuracy (cell error ā¤Ā±5mV) and pass 2500V DC/1min insulation tests.

- Environmental: Ensure no cracks under vibration (10Hzā2000Hz, 0.5gĀ²/Hz PSD) and no blistering after 85ā/85%RH/168hr tests.

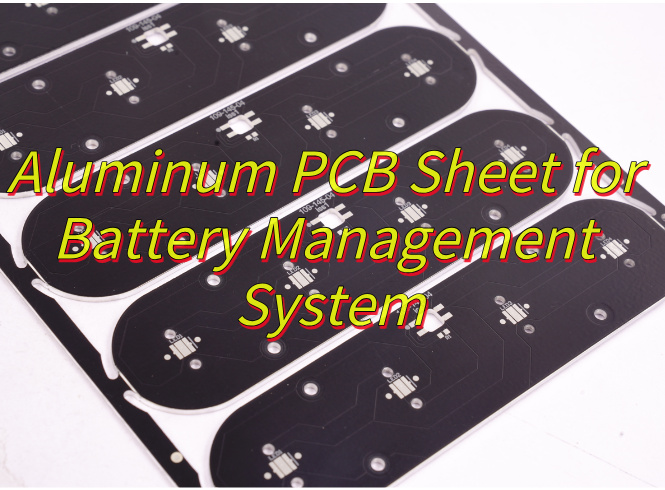

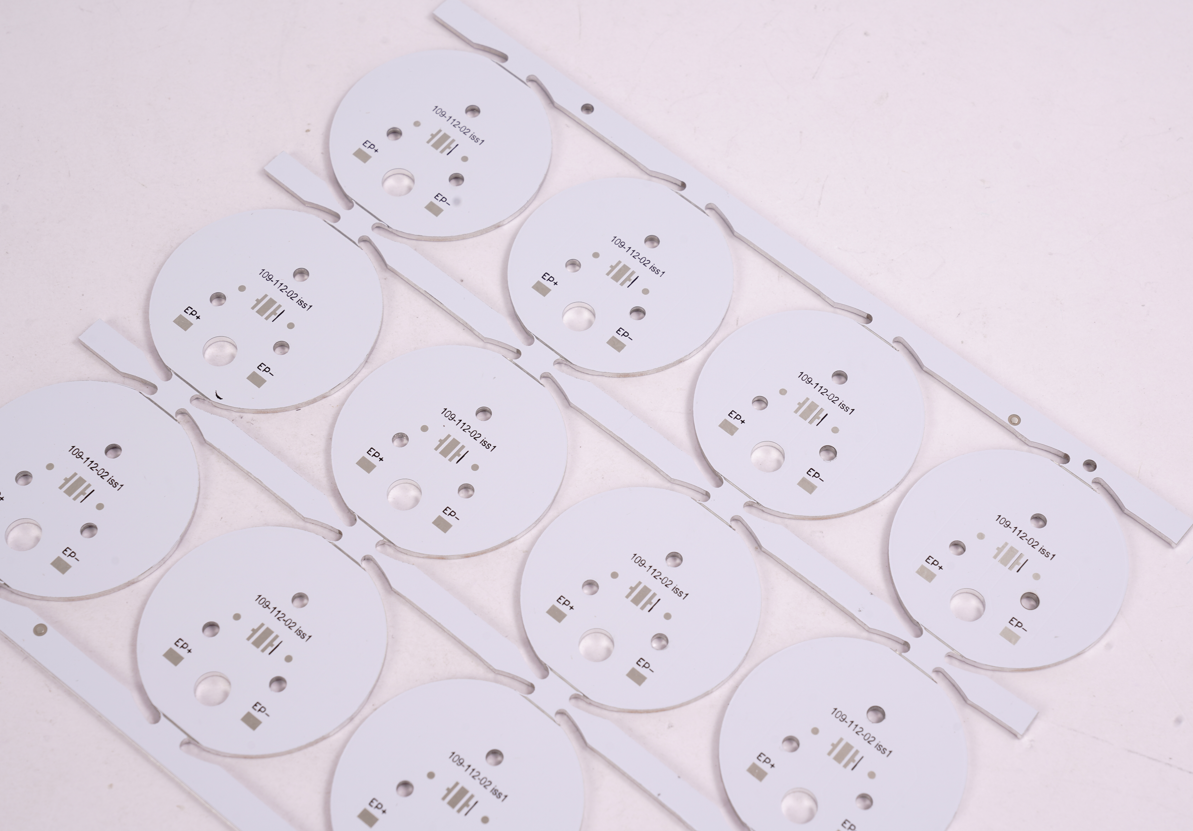

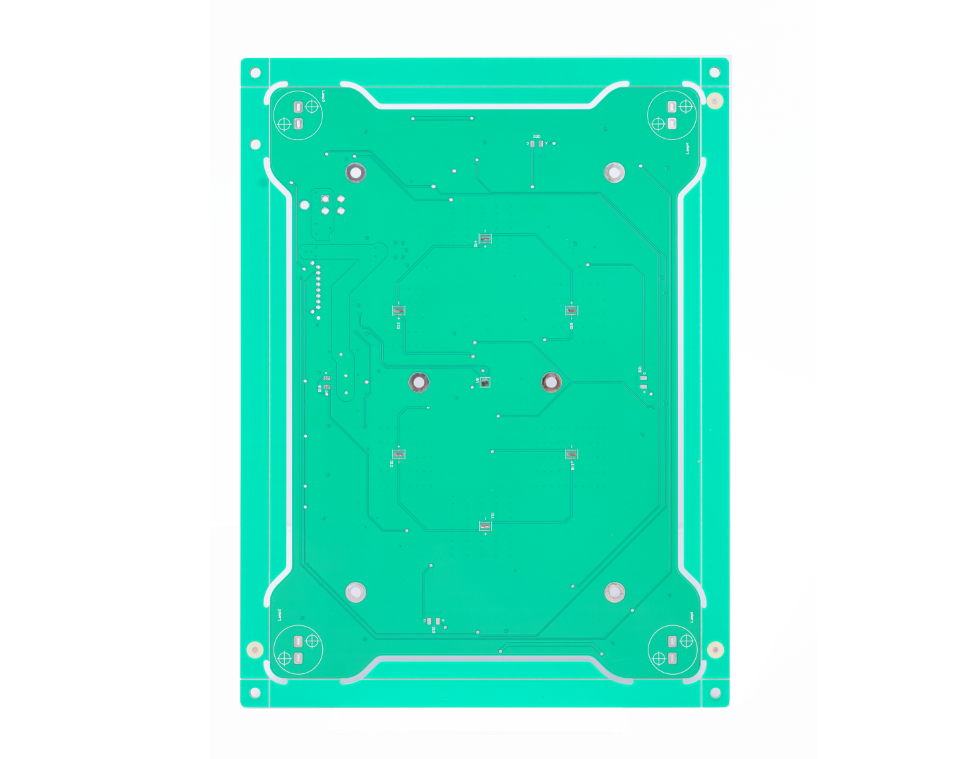

Our BMS Aluminum PCB Sheet Case Studies Ā

At EBest Circuit (Best Technology), we specialize in BMS aluminum PCB sheet design, manufacturing and assembly over 19 years. We can provide you full turnkey solution from design to final assembly. Below are BMS aluminum PCB samples we made before.

Attached is product specification for standard BMS aluminum PCB:

| Parameterā | āSpecificationā |

| āProduct Nameā | Standard BMS Aluminum PCB |

| āMaterialā | 6061-T6 aluminum substrate + high-thermal-conductivity epoxy resin (dielectric layer) |

| āThicknessā | 1.0mm / 1.5mm / 2.0mm (standard) |

| āCopper Thicknessā | 35Ī¼m (1oz) / 70Ī¼m (2oz) (standard) |

| āSolder Maskā | Green solder resist (standard) |

| āLegendā | White silkscreen (standard) |

| āSurface Finishā | HASL (standard) |

| āProcessā | Laser cutting / CNC drilling (standard) |

| āApplicationā | Battery Management Systems (BMS) |

Why Choose EBest Circuit (Best Technology) as BMS Aluminum PCB Supplier?

- Quality Certification System: Dually certified to ISO 9001 and IATF 16949, covering the entire process from material procurement to finished product testing. Optional medical-grade ISO 13485 compliance solutions meet the reliability requirements of medical device BMSs.

- Flexible Cost Control: A gradient selection of 3W/mĀ·K economical aluminum substrates to 8W/mĀ·K high-end aluminum nitride substrates is available, balancing performance and budget. The direct supply model eliminates middlemen, reducing costs for bulk orders by 15%-20%.

- Rapid R&D Support: Aluminum substrate samples are delivered within 24 hours, accelerating BMS prototype verification. Free Design-For-Made (DFM) optimization services proactively identify design flaws (such as insufficient thermal vias and close copper foil spacing), reducing revisions and development costs by 40%.

- Supply Chain Stability: Core materials (aluminum, copper foil, and thermal adhesive) are developed and produced in-house, eliminating third-party delays and achieving a 98% on-time delivery rate. We support small-batch trial runs of 50 units to mass production of 10,000 units, meeting full-cycle requirements.

- One-stop service chain: Covering PCB layout (compatible with Altium/PADS), thermal simulation (ANSYS Icepak), SMT assembly, and more. The engineering team is deeply involved in BMS architecture design, optimizing the balance between thermal layout and electrical performance.

- Environmental compliance: RoHS/REACH certification, the use of recycled aluminum and lead-free processes reduce the carbon footprint by 25%. The corrosion-resistant aluminum substrate adapts to a wide operating temperature range of -40Ā°C to 85Ā°C, extending the service life of the outdoor BMS.

- Fast technical support: The global engineering team responds 24/7, resolving issues such as thermal runaway and EMC interference within an average of 4 hours. This is particularly suitable for scenarios where downtime costs are sensitive, such as electric vehicle charging station BMSs.

How to Get a Quote for Aluminum PCB?

To receive an accurate quote for aluminum PCB, please provide the following details:

- Aluminum PCB Dimensions: Length Ć Width Ć Thickness (including tolerance requirements)

- Number of Layers: Single-Sided/Double-Sided/Multi-Layer (specify number of layers)

- Material: Aluminum type (e.g., AL-5052) and thermal conductivity (e.g., 2.0 W/mĀ·K)

- Surface Finish: HASL/ENIG/OSP (thickness requirements can be specified)

- Quantity: Sample (1-10 pcs)/Small Batch (50-500 pcs)/Mass Production (>1000 pcs)

- Special Requirements: Thermal Via Design, Impedance Control, etc.

Why Choose EBest Circuit (Best Technology)?

- 24-Hour Fast Response: Quote within 1 business day of submitting your request.

- Free DFM Optimization: Pre-review of designs by our engineering team to reduce development risk.

- Quality Assurance: ISO dual certification + 100% AOI inspection.

Welcome to contact us if you have any inquiry for aluminum PCB: sales@bestpcbs.com.

Tags: aluminum pcb, aluminum PCB sheet