What is 6 oz copper PCB? This guide covers specs, benefits, applications, manufacturing process, manufacturer selection, lead time for 6 oz copper PCB.

Are you worried about these problems?

- Are high-current applications plagued by heat dissipation issues?

- Circuit burnouts leading to frequent after-sales service calls?

- Is low production yield driving up overall costs?

EBest Circuit (Best Technology) can provide service and solution:

- 6oz copper layer + thermal management design – improves heat dissipation efficiency by 60%, ensuring continuous and stable operation.

- 210μm thick copper + optimized overcurrent – single-line carries 35A, completely eliminating the risk of board burnout.

- High-TG material + vacuum lamination process – 99.5% batch yield, worry-free delivery.

Welcome to contact us if you have any inquiry for heavy copper PCB: sales@bestpcbs.com.

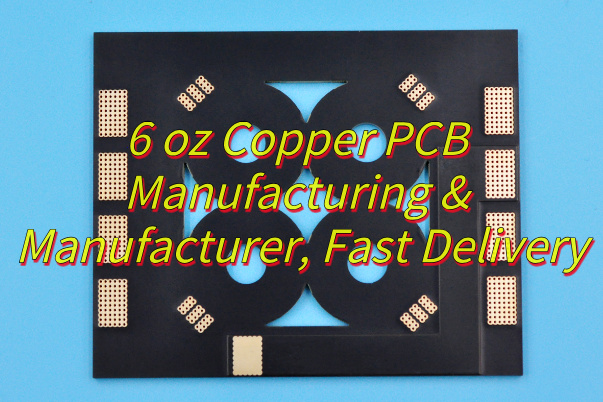

What is 6 oz Copper PCB?

6 oz Copper PCB refers to a printed circuit board with copper foil thickness of 6 ounces per square foot (≈210 µm or 8.4 mils). This ultra-thick copper layer enables exceptional current handling (up to 50A+ per trace) and thermal dissipation, making it ideal for high-power applications like EV chargers, industrial motor controls, and RF power amplifiers. Manufacturing requires specialized processes: extended alkaline etching times to avoid undercut, high-temperature lamination for copper-substrate adhesion, and reinforced plating to prevent warping. While costing 30-50% more than standard 1 oz PCBs, it reduces thermal stress-induced failures by 40% and eliminates the need for external heatsinks in compact designs.

6 oz Copper PCB Specification

| Parameter Category | Specification | Metrics |

| Material Base | Copper layer thickness | 6 oz (210 μm) ±5% |

| Substrate Type | Available materials | FR4/CEM-3/Aluminum-based PCB |

| Copper Finish | Surface treatment | HASL/ENIG/OSP/Immersion Silver |

| Minimum Line Width | Etched line width | 8 mil (0.2mm) @1 oz |

| Minimum Spacing | Line-to-line clearance | 8 mil (0.2mm) |

| Plating Thickness | Minimum via copper plating | 1 mil (25 μm) |

| Warpage | PCB deformation | ≤0.5% (300mm board) |

| Thermal Resistance | Heat shock test | No delamination after 288℃/10s |

| Thermal Performance | Thermal resistance (FR4) | ≤1.5℃/W (single layer) |

| Solder Mask | Minimum aperture size | 10mil×10mil |

Why Choose 6 oz Copper PCB?

Advantages of 6 oz copper PCB:

- High current carrying capacity: Supports over 50A per trace, eliminating the need for external heat sinks, saving space and cost.

- Excellent thermal management: Copper’s high thermal conductivity (386 W/m·K) reduces junction temperature by 25-40%, extending device lifespan.

- Cost-effectiveness: While costing 30-50% more, eliminating heat sink components and reducing failures yields significant long-term savings.

- Global compliance: Meets IPC-6012 Class 3, RoHS/REACH, and UL 94 V-0, simplifying market entry.

- Design flexibility: Enables miniaturization of high-power devices, such as industrial controllers, by 40%.

- Long-term reliability: Withstands three times the thermal cycling stress, reducing field failure rates by 70%, ensuring long-term product operation.

When to Use 6 oz Copper PCB?

Applications of 6 oz copper PCB:

- Electric vehicle (EV) charging modules: Handling DC fast charging at 200A+, 6oz copper foil ensures trace temperature rises of less than 5°C, preventing the risk of battery thermal runaway.

- Industrial motor controllers: When driving motors over 50kW, they handle transient current peaks and reduce IGBT module overheating and failure.

- RF power amplifiers: 5G base station transmitters require 6oz copper substrates for heat dissipation to ensure GaN devices operate at safe junction temperatures.

- Solar inverters: When DC bus voltages reach 1500V, thick copper PCBs reduce DC link resistance losses (<3mΩ).

- Aerospace power systems: Satellite payloads require wide operating temperatures from -55°C to 125°C, and 6oz copper foil mitigates thermal expansion coefficient mismatch.

- Medical laser equipment: Pulsed 2000W laser drivers require instantaneous heat conduction. Thick copper PCBs replace liquid cooling solutions to improve system reliability.

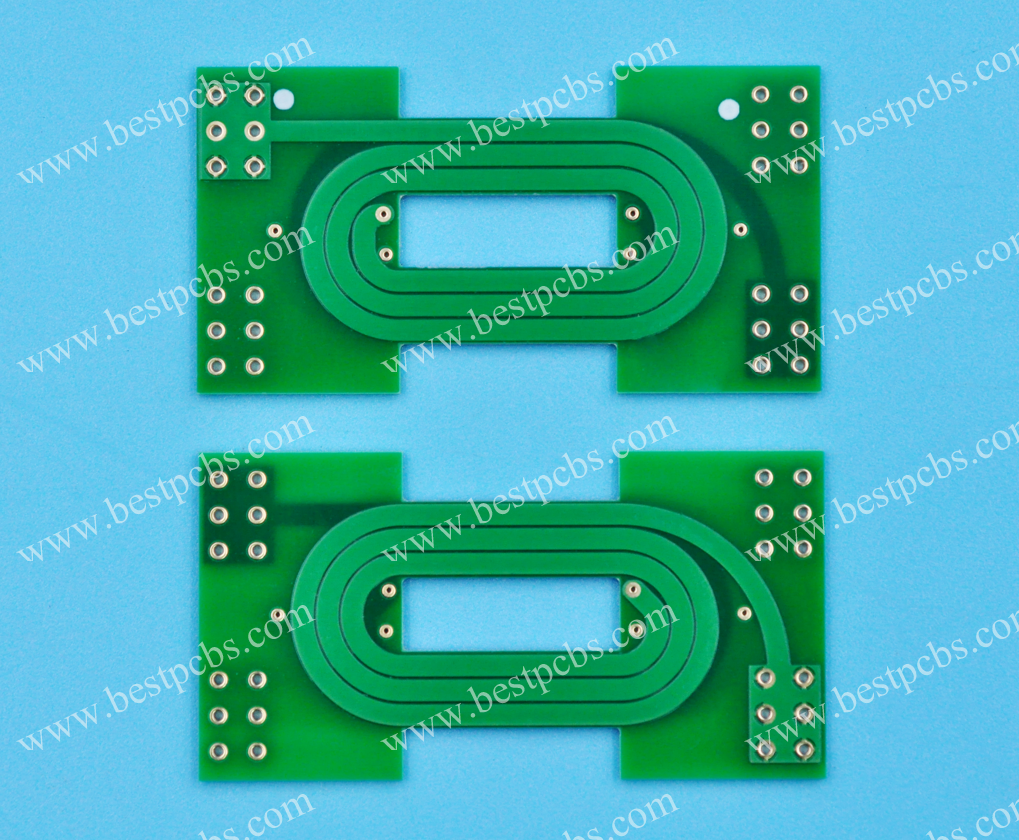

How to Make A 6 oz Copper PCB?

6 oz Copper PCB Manufacturing Processes:

1. Material Preparation

- Select 210μm (6oz) high-purity electrolytic copper foil.

- Choose FR-4 (Tg≥170℃) or CEM-1 substrate based on thickness requirements.

- Remove copper oxide layer via chemical etching (H₂SO₄ 10% + H₂O₂ 5%) and ultrasonic cleaning.

2. Inner Layer Circuit Fabrication

- Laminate 50-75μm dry film using a hot roller (110-120℃, 0.3-0.5MPa).

- Expose with LDI (355nm wavelength, ±2μm accuracy) and develop with 0.8-1.2% Na₂CO₃ solution.

- Etch 3oz copper in alkaline solution (50℃, 120 seconds), then laminate low-flow PP sheets (180℃/120min) and etch remaining 3oz copper.

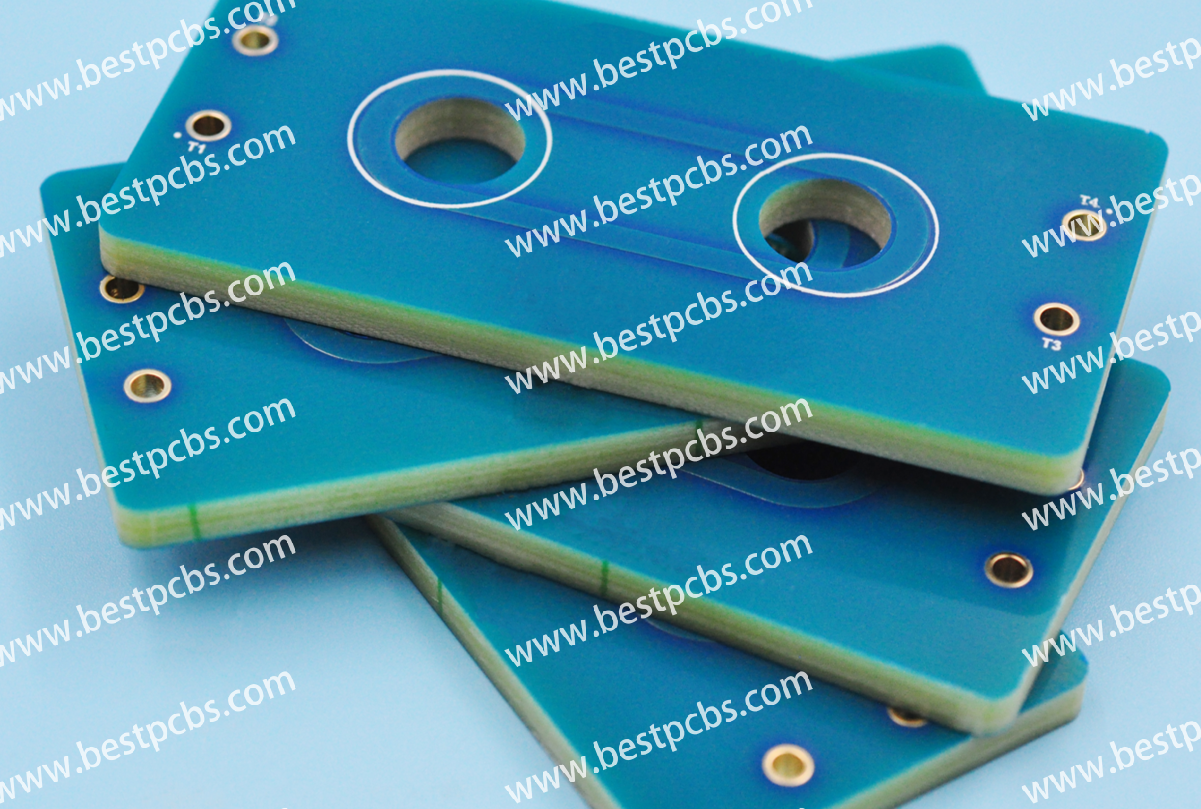

3. Lamination Process

- Stack symmetrically (inner layer: 18μm thin copper foil; outer layer: 70μm thick copper foil).

- Press with three-stage parameters: low pressure (5kg/cm²), medium pressure (15kg/cm²), high pressure (30kg/cm², 180℃, 120min).

4. Outer Layer Circuit Fabrication

- Repeat dry film lamination, exposure, and development processes.

- Etch outer layer using acidic solution (CuCl₂ 180g/L, HCl 50g/L, 25℃, 180 seconds).

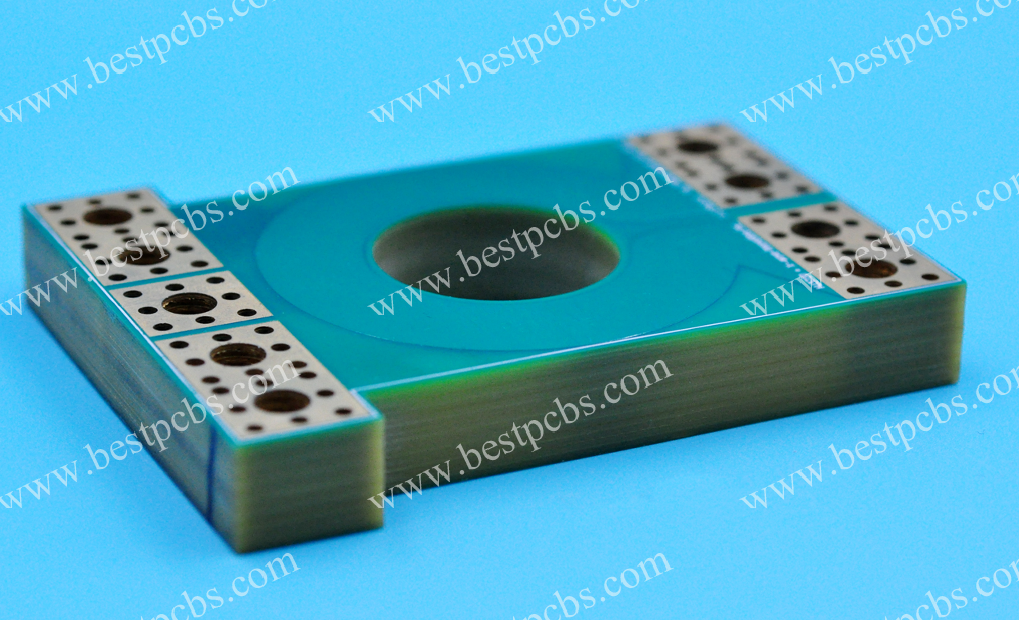

5. Drilling & Plating

- Mechanical drilling (diameter 0.3-3.0mm, 80kRPM, 0.8m/min feed rate).

- Chemical copper deposition (Pd catalyst, ≥25μm thickness).

- Pattern plating to reach 6oz (210μm) copper thickness (2.0A/dm², 120min).

6. Surface Finish

- Apply OSP (0.2-0.5μm) or ENIG (nickel 3-5μm, gold 0.05-0.1μm).

7. Testing & Packaging

- Electrical test (flying probe or universal grid, ±10% impedance accuracy).

- AOI inspection (line width/spacing tolerance ±15μm).

- Vacuum packaging with moisture-proof bags (storage: ≤30℃, ≤60%RH).

How to Choose a 6 oz Copper PCB Manufacturer?

Verify technical capabilities and equipment compatibility

- Require manufacturers to provide past case studies demonstrating their ability to control copper thickness uniformity within ±3μm (e.g., using pulse plating technology).

- Inquire whether they support locally thick copper designs or step-coated copper foil lamination processes (e.g., copper foil adhesion reaching 1.8N/mm²).

- Prefer manufacturers that use low-flow PP and symmetrical structural designs to reduce thermal stress.

Verify quality management systems and certifications

- Prefer manufacturers with automotive-grade and UL certifications.

- Require multi-stage inspection reports, including incoming material inspection, in-process inspection (using a professional thickness gauge for real-time monitoring), and post-assembly testing (impedance control tolerance within ±7%).

Investigate special process support capabilities

- Confirm whether vacuum heat-melting technology is available (to improve copper layer bonding and be suitable for high-reliability scenarios).

- Understand the minimum mechanical drill hole size and copper thickness deviation (≤5%) for blind and buried vias.

Analyze case studies and customer feedback

- Require case studies from actual applications such as high-voltage modules and medical devices. Learn customer reviews through industry channels, focusing on lead times and after-sales response speed.

Evaluate cost-effectiveness and delivery time

- While ensuring quality, compare quotes from different manufacturers and be aware of hidden costs (such as special processing surcharges and expedited service fees).

- Confirm whether expedited service (such as 12-hour/24-hour express delivery) is available.

Inspect equipment advancements and technological updates

- Prefer manufacturers that use advanced electroplating equipment, vacuum laminators, and X-ray coating thickness gauges.

- Check whether the manufacturer consistently invests in R&D (such as innovations in ultra-thick copper processing).

Supply chain stability and raw material control

- Understand whether the manufacturer’s raw material procurement channels are reliable and whether they can cope with copper price fluctuations or shortages.

- Request raw material quality inspection reports to ensure that the substrate, copper foil, and other materials comply with industry standards (such as IPC-4101).

6 oz Copper PCB Manufacturing Lead Time

1. Standard Production Cycle

Prototype Stage (1-2 Layers)

- Normal Delivery: 5-7 Days (Including Engineering Review)

- Expedited Service: 3 Days (30% Expedited Fee Applicable)

Mass Production Stage (4 Layers and Above)

- Normal Delivery: 12-15 Days (Including Impedance Testing)

- Rapid Production: 8-10 Days (Material Pre-Stock Required)

2. Influencing Factors

Process Complexity

- 6 Etching the 6 oz copper layer requires pulse technology, which increases the time by 40% compared to conventional processes.

- Lamination of multilayer boards requires three-stage temperature control (80°C → 160°C → 190°C), totaling 24 hours.

Quality Inspection Requirements

- Copper thickness tolerance testing (±5%) adds 8 hours to the testing time.

- High-current designs require additional thermal shock testing (288°C/10s), adding 12 hours.

Supply Chain Factors

- Special substrates (such as aluminum substrates) can extend procurement cycles by 2-3 days.

- Surface treatment process differences: ENIG takes 8 hours longer than HASL.

3. Optimization Suggestions

- Using standardized designs can reduce engineering confirmation time by 2 days.

- Pre-review of DFM documents reduces the risk of rework.

- Selecting a supplier with dedicated 6 oz lines can improve efficiency by 20%.

How Much Does a 6 oz Copper PCB Cost?

Price Range

- Basic Designs: $100–$300 per square foot (single/double-layer).

- Advanced Designs: Over $500 per square foot (multilayer, blind/buried vias, high-frequency materials).

Factors Affecting Price:

- Copper Thickness: Each additional ounce increases material costs by ~60%.

- Process Complexity: Thicker copper requires longer etching/drilling times and specialized equipment.

- Design Specs: Narrow line widths (<4mil) or small via diameters (<0.2mm) raise costs.

- Production Volume: Large orders (>100k units) reduce per-unit costs by ~50% vs. small batches.

- Certifications: Military/IPC3 standards add 15–20% vs. basic quality checks.

For accurate pricing tailored to your project, contact EBest Circuit (Best Technology) at sales@bestpcbs.com. Our 19+ years of expertise in heavy copper PCBs ensure competitive quotes and reliable delivery. Looking forward to hearing from you soon!