Quick PCB fabrication is now a must in product development where every minute counts. From prototype to mass production, teams need reliable solutions that save time without compromising quality.

EBest Circuit (Best Technology) is an original factory in China providing quick PCB fabrication service with rapid quotes. We offer a wide PCB range for your selection, including FR4 PCB, rigid-flex PCB, MCPCB, ceramic PCB, and PCBA. As a customer-focused PCB manufacturing company, EBest Circuit (Best Technology) prioritizes quick fabrication quality and meets your lead time requirements. Our factory adheres to AS9100D during every PCB fabrication process. If you have any rapid PCB fabrication needs, contact us at sales@bestpcbs.com. We are happy to provide our full engagement to you at any time.

What is Quick PCB Fabrication?

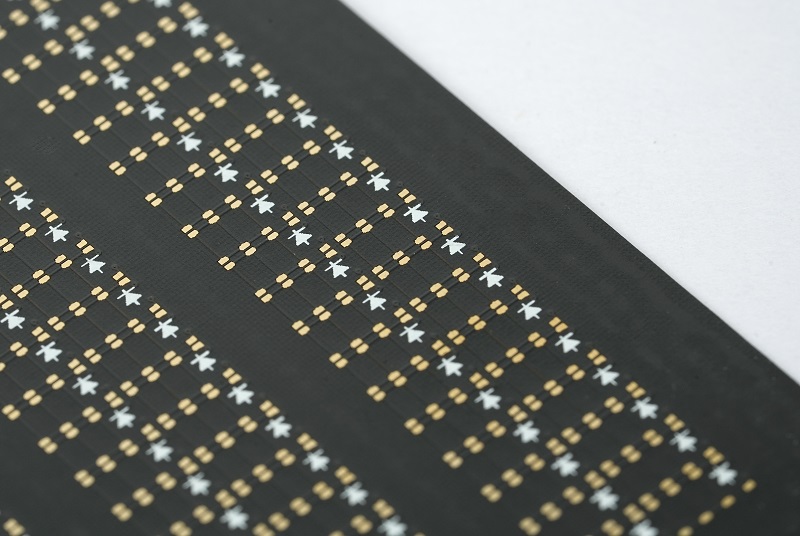

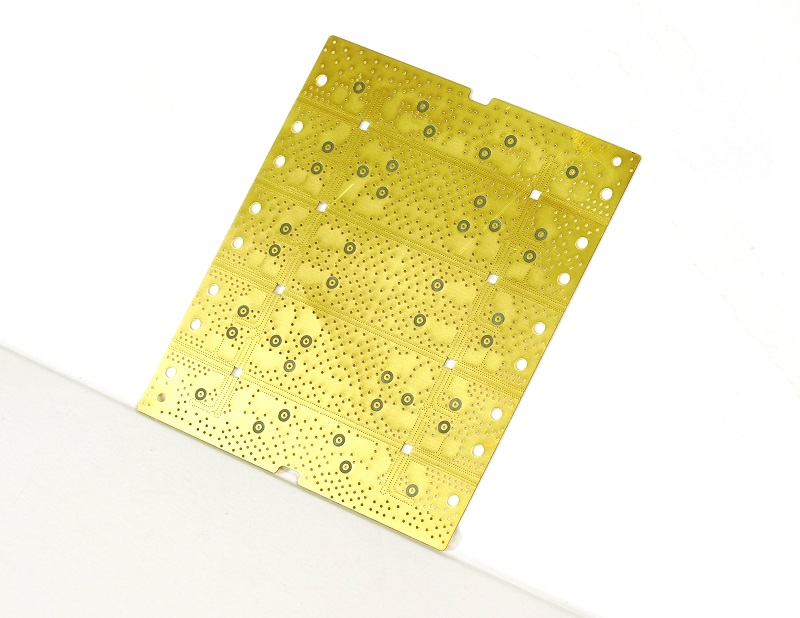

Quick PCB fabrication refers to the fast production of printed circuit boards, often within 24 to 72 hours. It focuses on speeding up design verification or production schedules. This method is crucial for startups, hardware teams, and R&D departments that rely on time-sensitive innovation. It also supports custom PCB needs and accommodates both rigid and flexible PCB designs.

How Long Does It Take to Fabricate a PCB?

The time depends on complexity and volume. For single-layer or double-layer boards, it can take 24 to 48 hours. Multilayer or HDI PCBs may require 3 to 7 days. EBest Circuit (Best Technology) offers PCB quick turnaround for urgent needs by integrating MES systems and automatic scheduling. We shorten the process without affecting quality.

How Much Does a Quick PCB Fabrication Cost?

Prices vary based on board type, size, layer count, and surface finish. Standard prototypes start around $50 to $150. More complex builds cost more. Fast delivery adds a premium, but EBest Circuit (Best Technology) balances speed and value. We optimize the process, use localized sourcing, and manage supply chains to reduce your total cost.

What is Rigid PCB vs Flex PCB?

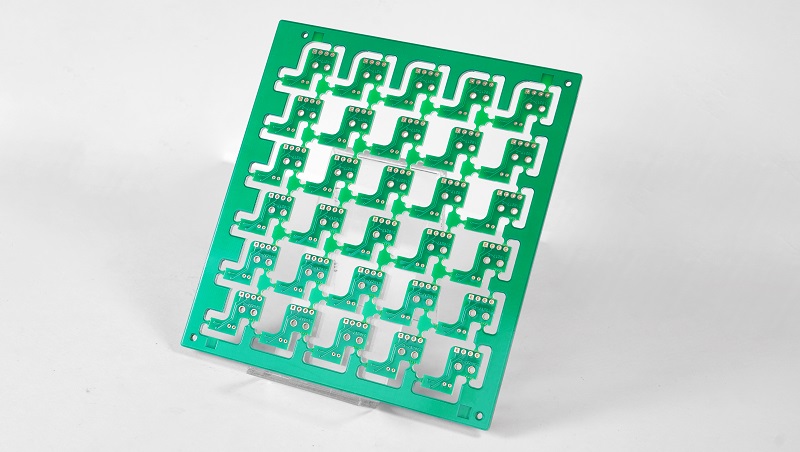

Rigid PCBs are solid and maintain shape. Theyâre used in laptops, servers, and automotive electronics. Flex PCBs are bendable and ideal for wearables, cameras, and medical devices. EBest Circuit (Best Technology) also provides rigid-flex options for advanced layouts. Our engineers help choose what works best for your application and speed up your quick pcb design.

What Are the Applications of Quick PCB Fabrication?

Quick PCB fabrication is used in sectors where delays arenât acceptable. Medical prototypes, aerospace modules, EV chargers, and communication devices all benefit. These products often need updates during testing. Thatâs where quick turn PCB manufacturers shine, making iterations fast and affordable.

What is the Benefit of Quick PCB Fabrication?

Faster development helps you meet tight deadlines. It allows early detection of design errors. It speeds time-to-market. With shorter production cycles, you cut down project delays. Quick services also reduce the pressure on your engineering team. EBest Circuit (Best Technology) supports your goals with smart planning and automated testing.

Why Should You Choose EBest Circuit (Best Technology) as Your Quick PCB Fabrication Manufacturer?

EBest Circuit (Best Technology) is more than a quick PCB manufacturer. We understand real project needs. Many clients face delays due to incomplete coordinate files, missing solder masks, or acid trap designs. We offer a pre-review service to catch these early. This avoids mistakes that slow delivery.

- Also, small batch orders often get sidelined. Not with us. Our team prioritizes each order fairly. We use MES system for efficiently material tracking. This lets us take in rush orders while keeping commitments.

- Some worry about quality with fast services. Thatâs valid. But EBest Circuit (Best Technology) has strict AOI, flying probe, and X-ray inspection. Each board is verified before shipping. We deliver speed with zero shortcuts.

- Another challenge is supply chain bottlenecks. Many factories still use manual planning. Itâs slow. Weâve automated it. Our smart sourcing, local stock, and ERP system let us move fast even when global logistics are tight.

- We also lead in technical skill. Whether itâs high-density interconnects or micro-vias, our team handles complex builds. Weâve adopted new methods like LDI and fine-line etching. This makes our service ideal for today’s compact and demanding products.

- In terms of flexibility, we provide quick turn PCB assembly, not just bare boards. SMT lines are ready for 24-hour shifts. We can support urgent launches. Our quick turn PCB fabrication orders are finished and shipped reliably and quickly to your doorstep.

- We know clients also value support. Our engineers are always ready. We assist with stackup, impedance, and materials. Customization is our core, and we back it with technical insight.

- To add to that, our quoting process is fast and simple. You get your quote within hours. This helps you move forward smoothly. Quick quotes also show how organized and experienced a team is. Weâve refined ours to meet your expectations.

- Lastly, we care about the environment. All our processes follow RoHS and REACH. Green manufacturing is not an option, it’s a priority. We work toward a sustainable future without slowing your progress.

In a nutshell, quick PCB fabrication is shaping the future of product design. Rapid quotes, PCB fabrication quality, and before and after sales service are what matter. EBest Circuit (Best Technology) delivers all three. Our clients trust us because we understand their requirements and act fast. Whether you need a custom PCB, 24 hour PCB service, or PCB printer support, weâre here to help. Feel free to contact us at sales@bestpcbs.com for your inquiries details. With EBest Circuit (Best Technology), you gain a reliable PCB fabrication partner for every project timeline.

Tags: Quick PCB Fabrication, Rapid PCB Fabrication, Rapid Quotes