EBest Circuit (Best Technology) is a leading ceramic PCB manufacturer with over 18 years of experience delivering premium-quality printed circuit boards to customers around the world. We specialize in ceramic PCB substrates, especially AlN ceramic substrates, for high-performance applications.

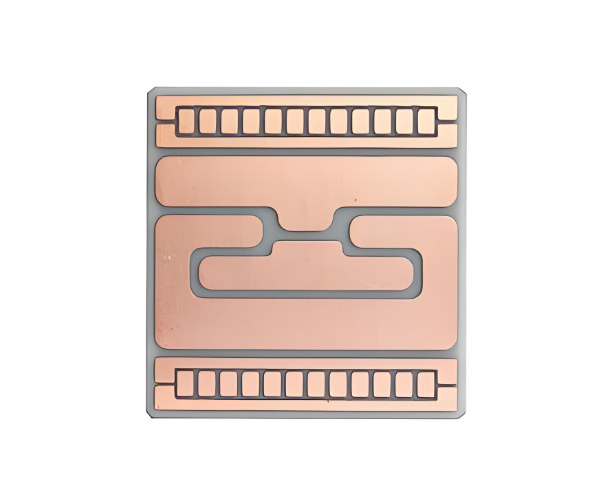

From Direct Plated Copper (DPC) aluminum nitride aln ceramic substrates to thick-film hybrid circuits, our products are trusted in sectors like automotive, aerospace, LED lighting, power electronics, and RF communication. Whether you need high thermal conductivity materials, customized substrate thickness, or precision copper metallization, we deliver with speed and accuracy.

What Is Aluminum Nitride (AlN) Ceramic Substrate?

An AlN ceramic substrate is an advanced ceramic material made by sintering aluminum nitride powder at high temperatures. It combines excellent thermal conductivity with strong electrical insulationâa rare but valuable combination.

Unlike traditional FR4 or even alumina (AlâOâ), aluminum nitride ceramic boards handle both heat and voltage in compact, high-power systems. Thatâs why theyâre widely used in:

- High-power LED modules

- IGBT and MOSFET packages

- Power modules for EVs

- 5G and RF components

- Aerospace and defense electronics

With DPC (Direct Plated Copper) technology, AlN substrates are layered with thick copper (35μmâ300μm), allowing for efficient heat spreading and high current handling.

What Are the Material Properties of AlN?

Aluminum nitride delivers a powerful balance of properties that few ceramics can match:

| Material Property | Unit | Value | |

| Color | White Grey | ||

| Medium grain size | um | 3-5 | |

| Surface roughness (Ra) | um | 0.3-0.5 | |

| Density | Kg/m3 | >3300 | |

| Rate of water absorption | % | 0 | |

| Bending strength | 4 point method (40x4x3mm3) | Mpa | 400 |

| Dual ring method (0.63mm substrate thickness) | Mpa | 500 | |

| Thermal conductivity (20-100â) | W/m-k | >=170 | |

| Specific heat | J/kg.K | 800 | |

| Coefficient of Linear expansion | 1*E-6 / K | 4.4 | |

| Dielectric constant | ã | 9.0+/-10% | |

| Dielectric loss factor (1 MHz) | 1*E-3 | 0.3 | |

| Breakdown Voltage | 2.0mm substrate | KV/mm | 34 |

| 1.0mm substrate | 17 | ||

| 0.635mm substrate | 11 | ||

| Volume resistivity | 20â | Ohm * cm | – |

Aluminum Nitride Thermal Conductivity vs. Temperature

One of the standout features of AlN is its thermal conductivity, often ranging from 160 to 180 W/m·K. However, conductivity changes with temperature.

- At room temperature: ~170â180 W/m·K

- At 300°C: Drops slightly to ~150 W/m·K

- At 500°C: May fall to ~130 W/m·K

This predictable behavior allows engineers to model heat dissipation accurately. Unlike FR4 or alumina, AlN can handle continuous high temperatures without degrading or delaminating. Our DPC AlN ceramic PCBs at EBest Circuit (Best Technology) are tested for thermal cycling, ensuring they perform reliably under dynamic load conditionsâespecially in EVs, telecom equipment, and military electronics.

What Is the Difference Between Ceramic Substrate and FR4?

This is a common question from design engineers and procurement teams alike. Ceramic substrates (such as aluminum nitride (AlN), alumina (AlâOâ), and silicon nitride) and FR4 PCBs are used in very different types of applications, even though both serve as the base materials for electronic circuits. Their differences go far beyond appearance and costâthey impact performance, reliability, and product lifespan.

Hereâs a detailed breakdown of the key differences between ceramic substrates and FR4 PCBs:

| Feature | Ceramic Substrate (AlN, AlâOâ, SiâNâ) | FR4 PCB |

| Thermal Conductivity | Very high (AlN: 170â180 W/m·K, AlâOâ: 20â30 W/m·K) | Low (~0.3â0.4 W/m·K) |

| Electrical Insulation | Excellent (ideal for high-voltage applications) | Good, but breaks down at high heat |

| Heat Resistance | Can operate >500°C | Limited to ~130â150°C continuous |

| Dielectric Constant (High Frequency) | Stable, low-loss | Less stable, higher losses at GHz |

| Coefficient of Thermal Expansion (CTE) | Matches semiconductor materials like silicon | Higher, may cause stress and delamination |

| Mechanical Strength | High, especially with silicon nitride | Moderate, prone to cracking under thermal cycles |

| Miniaturization Capability | Supports fine pitch, thin lines | Limited to standard line widths |

| Chemical Stability | Inert, resists corrosion and oxidation | Sensitive to moisture and chemicals |

| Signal Integrity | Excellent for high-frequency and high-speed signals | Susceptible to cross-talk and signal loss |

| Thermal Cycling Performance | Outstanding for power modules | Weaker in applications with frequent heating and cooling |

| Moisture Absorption | Very low (typically <0.01%) | Higher (can absorb up to 0.1% or more) |

| Design Flexibility | Suitable for multilayer, 3D packaging | Mostly used in 2-layer or 4-layer boards |

| Weight | Heavier, especially with metal coatings | Lightweight |

| Cost | Higher upfront cost, longer lifespan | Lower initial cost, shorter lifespan |

| Applications | Power electronics, LEDs, lasers, RF, EVs | Consumer electronics, computers, IoT |

How Thick Is Aluminum Nitride Substrate?

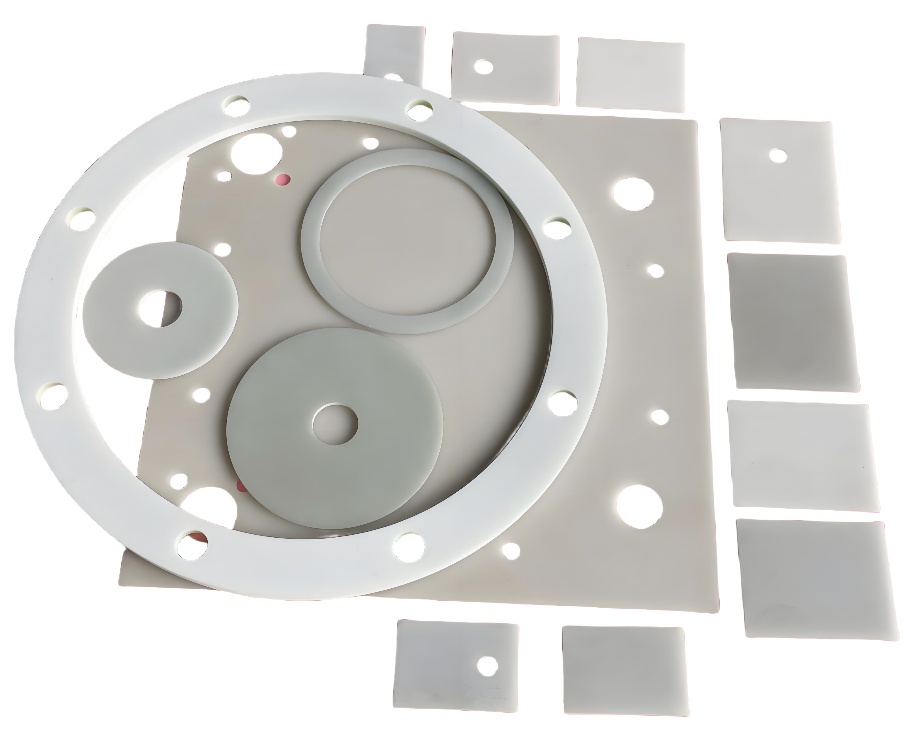

The typical thickness of an AlN substrate ranges from 0.25 mm to 2.0 mm, depending on the application. Thinner boards are used in space-constrained designs like portable RF devices. Thicker versions are preferred in power modules and thermal management systems.

EBest Circuit (Best Technology) supports a wide range of substrate thicknesses, such as:

- 0.25 mm for sensors and miniaturized circuits

- 0.38 mm or 0.5 mm for LED modules

- mm and 2.0 mm for high-power electronics

- Custom thickness options available upon request

Our team evaluates your thermal and electrical needs to recommend the optimal ceramic board thickness.

What Is an Alternative to Aluminum Nitride?

While AlN is powerful, itâs not always the default choice for every budget or function. Alternatives include:

- Alumina (AlâOâ): Lower cost, but only 20â30 W/m·K thermal conductivity

- Silicon nitride (Si3N4) substrate: Good thermal and superior mechanical strength

- Beryllium oxide (BeO): High thermal performance, but health concerns during processing

Of these, silicon nitride stands out as the closest functional competitor. It’s mechanically superior but falls behind in thermal conductivity. In many cases, choosing between the two comes down to application specificsâspace, vibration, power load, and cost.

AlN Ceramic Substrate vs. Silicon Nitride Substrate

Letâs take a closer look at how AlN and silicon nitride compare:

| Property | AlN Ceramic Substrate | Silicon Nitride Substrate |

| Thermal Conductivity | 170â180 W/m·K | 70â90 W/m·K |

| Mechanical Toughness | Good | Excellent |

| Electrical Insulation | High | Moderate |

| Dielectric Strength | High | Moderate |

| CTE Match with Silicon | Close | Slightly higher |

| Weight | Lighter | Heavier |

In high-vibration environments such as engine control units, silicon nitride is a strong choice. But in RF, LED, or power modules, AlN ceramic boards are the go-to for managing heat and electrical insulation.

DPC AlN Ceramic Substrate Market Trend

The DPC AlN ceramic substrate market is experiencing remarkable growth due to the explosion of high-frequency and power-dense electronics. Key market drivers include:

- Electric vehicles: IGBT modules and inverters demand high-thermal substrates

- 5G infrastructure: Base stations and RF filters use ceramic substrates

- LED lighting: High-power LEDs need efficient thermal paths

- Defense and aerospace: Require reliable materials with long service life

- Industrial power: Servo drives, CNCs, and high-voltage equipment depend on thermal stability

Global market studies forecast a CAGR of 8â12% in the AlN ceramic sector. The increasing demand also impacts the AlN ceramic substrate price, which may rise due to material cost and purity level. At EBest Circuit (Best Technology), we maintain strong relationships with raw material suppliers, ensuring competitive pricing, high-quality sourcing, and fast lead times.

FAQs about AlN Ceramic Substrate

1. What is the current AlN ceramic substrate price?

Prices vary based on thickness, purity, metallization, and quantity. But ceramic PCB price is always higher than FR4 PCB. Expect around $2 to $10 or even $50 per piece for custom solutions. Bulk orders offer better rates.

2. Why choose DPC over other copper technologies?

DPC AlN ceramic substrates offer better adhesion, smoother copper layers, and more precise etching. Ideal for fine pitch designs and high-frequency modules.

3. Can I use AlN substrates for high-frequency RF circuits?

Yes. AlN offers a low dielectric constant (~8.8) and stable performance up to GHz frequencies.

4. Are AlN ceramic substrates environmentally safe?

Absolutely. They are non-toxic, inert, and recyclableâsafe for manufacturing and long-term operation.

5. Do you offer AlN substrates with plated vias?

Yes. EBest Circuit (Best Technology) provides vias, through-holes, and multilayer AlN ceramic substrates for complex 3D packaging.

Why Choose EBest Circuit (Best Technology) as Your AlN Ceramic Substrate Manufacturer?

- 18+ years of PCB manufacturing experience

- ISO9001, ISO13485, and IATF16949 certified

- In-house DPC/DBC/AMB/HTCC/LTCC/thick film/thin film processing with precise copper thickness control

- Custom AlN ceramic substrate solutions with fast prototyping

- Global shipping with professional support

- Proven success across EV, LED, medical, RF, and defense sectors

From prototype to production, EBest Circuit (Best Technology) provides tailored ceramic solutions that enhance reliability, extend product life, and help you build better electronics.

Tags: aln ceramic substrate, aln ceramic substrate price, ceramic substrate manufacturers, silicon nitride substrate