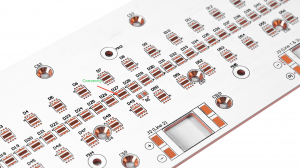

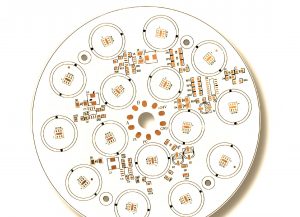

Sink Pad MCPCB is a special type of metal core PCB (short for MCPCB), the working principle is through the sink heat pad solder direct to the metal substrate (commonly copper or alumina substrate), so people also call it as Thermal pad MCPCB. Sink Pad MCPCB is popular recently due to its excellent heat dissipation and thermal conductivity. Since the copper is easy to get oxidation, coating a metal film is good for protecting the surface, such as ENIG, ENEPIG or OSP. Lead-free hot air solder leveling (HASL) also is a kind of surface treatment, but why we don’t suggest to apply it? Let me explain with you.

Why is HASL not recommended?

- Substrate

From the substrate aspect, due to the HASL process is to first dip the solder on the circuit board, then dip the solder flux in the melting, and finally blow off the excess solder on the printed board with the hot compressed air in the air knife through the two air knives, at the same time to eliminate the excess solder in the metal hole, so as to get a bright, smooth and uniform solder coating. Since most of customers prefer choose copper substrate as the base material (Aluminum core sink pad PCB thermal conductivity only could be 235 W/m.k, while Copper core sink pad PCB thermal conductivity could reach to 400 W/m.k). However, copper base is much heavier than alumina core, during the hot air knife scraping tin process, the copper surface is easy to be scratched and get damaged to affect the poor appearance and a short circuit risk. This is one of the reasons why HASL is not suitable for Sink Pad PCB.

- Structure

From the structure of the Sink Pad MCPCB, the LEDs Chip Thermal Pads solder contact to the copper substrate directly, no dielectric between LEDs heat out pads and the Metal core. As you can see the stack up as below, what Sink PAD PCB laminate is pure film, the adhesion is not very good, so there’s a risk of delamination if do HASL (lead free).

- Chemical

From the chemical aspect, due to the HASL (lead free) has the process of return the film, the potion will react with the copper chemically, which will bring the poor coating and poor adhesion, so we don’t recommend to use HASL on the Sink Pad MCPCB.

Advances of the Sink Pad MCPCB

- Thermal conductivity 235 To 400 W/m.

- Super good heat dissipation

- Power LED junction temperature

- Longer LED life

- Most economical direct thermal path solution

- Direct thermal path

- Different structure can be made according different design needs

When can we use Sink Pad MCPCB?

With so many kinds of PCB types, when and where can we use the Sink Pad MCPCB?

- The copper metal core has high density, strong thermal conductivity and carries heat effectively. That means, it is possible to dissipate the same heat using a smaller sink-pad MCPCB, as compared to regular MCPCBs. So it is suitable be used in small applications which need to apply in high temperature.

- Very popular with high power LED mounting, sink-pad MCPCBs with their thermoelectric separation structure, can minimize the lumens depreciation of the LED, thereby prolonging the life of the LED lamp. Sink-pad MCPCBs are suitable for mounting high-power LED lamps and COB packaged LEDs. Moreover, manufacturers can tailor the sink-pad MCPCB to match the different design requirement needs of any LED.

Best Technology is a professional Sink Pad MCPCB manufacturer for more than 16 years in Asia, we have strong engineering team and specialized sales team can provide most suitable solutions for your applications in a very short time. What we can provide not only include single layer Sink Pad MCPCB, we also can produce 2 layers, double layer and multi-layer Sink Pad MCPCB. View https://www.bestpcbs.com/products/sinkpad-board.htm to know our capability about Sink Pad MCPCB.