PCB assembly in Spain is a critical part of Europe’s electronics manufacturing sector, driven by consistent demand from automotive, telecommunications, and medical industries as Spain’s PCB market grows at a 2.1% CAGR through 2025. Businesses dependent on electronics production rely on high-quality PCB assembly in Spain to comply with strict EU regulatory standards, with both local and global providers delivering precise, tailored services that meet sector-specific needs.

Top 10 PCB Assembly Companies in Spain

| Company Name | Main Business | Core Advantages | PCBA Capabilities | Delivery Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | PCB design, prototype, manufacturing and assembly services | 20-year industry experience, 2-hour quick response, global supply chain, strict quality control | Prototype to mass production, SMT/DIP assembly, high-precision component mounting | 5-15 working days; urgent orders within 24-48 hours |

| Cipsa Circuits | PCB manufacturing, SMD assembly templates, thin film switches | 40+ years of experience, ISO 9001/14001 certified, global production facilities in Spain, India and China | Single/double/multilayer PCB assembly, rapid prototyping, custom PCB solutions | 7-20 working days |

| Celestica Valencia S.A.U. | PCB assembly, relays, industrial controls, electronics manufacturing services (EMS) | Multinational EMS expertise, over 500 employees, end-to-end solutions, after-sales service | High-precision SMT assembly, system-level assembly, cockpit display PCBA | 6-18 working days |

| Circuitos Impresos 2 CI, SL | Custom PCB manufacturing and assembly for industrial applications | Local Spanish support, flexible production, competitive pricing for small-to-medium batches | SMT/THT assembly, rigid PCB assembly, quality testing per IPC standards | 8-22 working days |

| Pro Circuits, SL | PCB assembly and electronic manufacturing for automotive and consumer electronics | Specialized in automotive-grade PCBA, fast turnaround, strict compliance with EU standards | Automotive PCB assembly, SMT assembly, functional testing | 5-16 working days |

Pain Points of PCB Assembly in Spain

- Strict EU regulatory compliance, including RoHS and REACH standards, adds complexity to production processes and drives up testing costs.‚Äč

- Local shortages of electronic components, particularly semiconductors, frequently lead to supply chain disruptions and production halts for local assembly operations.‚Äč

- Labor costs in Spain are higher compared to Asian manufacturing hubs, which directly increases the overall production expenses of PCB assembly projects.‚Äč

- It is challenging to find reliable local partners in Spain that possess the high-precision assembly capabilities required for complex PCB projects.‚Äč

- Specialized PCB materials and medical/automotive-grade components often have long lead time, delaying production progress.‚Äč

- Critical sectors such as medical electronics impose stringent quality standards, creating additional demands for medical-grade assembly.‚Äč

- Logistics hurdles, including delays in importing raw materials and exporting finished PCBA products, pose ongoing challenges for PCB assembly in Spain.

One-Stop PCB Assembly in Spain Service: From Prototyping to Mass Production

As a 20-year professional PCBA manufacturer, our one-stop service covers all key stages from prototyping to mass production, removing the need for Spanish clients to coordinate multiple partners and cut communication costs. Our core advantages include an industry-leading 5-year warranty covering the entire assembly and delivery process, ensuring long-term reliability and sparing clients from extra costs related to post-delivery failures. Our MES system enables full production traceability, recording component sources, procedures and test data to minimize quality risks and simplify troubleshooting. We also maintain a stable 99.9% on-time delivery rate that far exceeds the industry average, ensuring timely order fulfillment and helping clients avoid costly delays to their product launches.‚Äč

We have developed tailored solutions to address local PCB assembly pain points, combining global resources with local market insights. To solve local component shortages, especially for semiconductors and specialized parts, we built a diversified global supply chain with over 200 rigorously audited authorized EU suppliers and maintain local inventory of common, high-demand components in Spain for timely access to compliant materials. For EU RoHS and REACH compliance, we implement strict pre-production testing and in-process quality control, including BOM sorting and targeted compliance checks, to eliminate defects and meet all standards. We also mitigate high local labor costs via optimized supply chain management, centralized procurement and streamlined production, balancing cost and quality for Spanish clients.

How We Ensure On-Time Delivery for Spain PCBA Orders?

This is how we ensure on-time delivery for Spain PCBA orders:

- Global Supply Chain Network: We cooperate with over 200 rigorously audited, authorized suppliers worldwide, covering key component-producing regions in Europe, Asia and North America, with a supplier audit pass rate of 98% to ensure reliability. This diversified network effectively avoids local component shortages in Spain, especially for critical parts like semiconductors, shortens core semiconductor procurement lead times by 30%, and maintains a 99.5% on-time supplier delivery rate, enabling direct sourcing from the nearest qualified suppliers to accelerate production.

- MES System Scheduling: Our advanced MES system optimizes production plans based on order priority and component availability, monitoring every assembly step in real time with a data recording accuracy of 100%. It tracks production progress, equipment status and workforce allocation to proactively identify and resolve potential bottlenecks within 1 hour, adjusting schedules promptly to keep delivery on track, and improving production plan execution rate to 99.5% while reducing changeover time by 25%.

- Backup Component Stock: We maintain a dedicated local stock of common and high-demand components in Spain, including resistors, capacitors and key semiconductors, covering over 900 types of components with a stock satisfaction rate of 95.8%. This backup inventory allows us to quickly address unexpected component shortages, ensuring production continues without halting, cutting emergency component replenishment time by 80%, and avoiding costly delivery delays.

- Local Logistics Partnerships: We have established long-term cooperation with 3 professional Spanish logistics firms that cover 28 core cities in Spain, including Madrid, Barcelona and Valencia. These partners offer fast, secure delivery services, with a next-day delivery on-time rate of 99.8% in major urban areas and weekend delivery options, ensuring finished PCBA products reach clients across the country efficiently and safely, with an overall logistics delivery accuracy of 99.9%.

- Pre-Production Planning: Before assembly begins, our team conducts detailed pre-production planning, including design review, BOM list verification and EU regulatory compliance checks, with a BOM verification accuracy of 99.9% and a design defect detection rate of 98.2%. This thorough preparation avoids delays caused by design errors, material mismatches or non-compliance with RoHS and REACH standards, reducing pre-production delay risks by 75%.

Our Spain PCBA Quality Control Process

Below is a quality control process of our Spain PCB assembly:

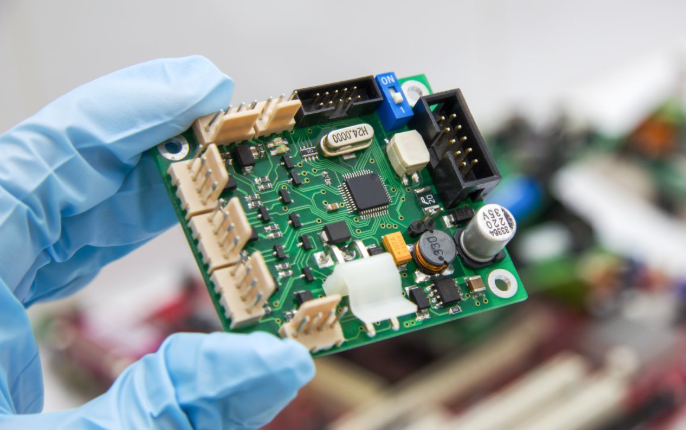

- Raw Material Inspection: Upon the arrival of all components and PCBs, we implement a two-step rigorous inspection process to eliminate quality risks from the source. First, we verify the supplier’s qualification certificates and batch information to ensure materials come from authorized EU suppliers, then conduct professional tests including appearance checks, electrical performance detection, and counterfeit identification. This strict process ensures all materials fully comply with EU RoHS 2.0 and REACH standards, with a raw material inspection pass rate of 99.9% and a 100% interception rate for counterfeit or defective components.

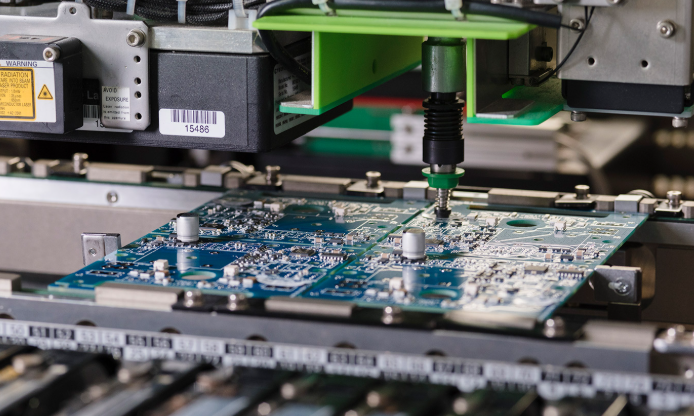

- In-Process Quality Control: Our professional team conducts full-process monitoring of every key step in SMT and DIP assembly, including solder paste printing, component mounting, and reflow soldering. We implement real-time patrol inspections every hour, and our MES system records detailed data of each operation from component placement coordinates to soldering temperature curves for full traceability. Once any abnormal issue is found, we suspend the corresponding production link immediately, with an abnormal response time within 1 hour, ensuring potential quality problems are resolved before proceeding to the next process.

- Advanced Testing Equipment: We are equipped with high-precision AOI, SPI, and FCT testing equipment to build a three-dimensional quality inspection barrier. SPI is used to detect solder paste printing quality, controlling solder paste thickness deviation within ¬Ī10őľm to avoid short circuits or poor soldering caused by uneven solder paste. AOI automatically scans PCBs from multiple angles to detect soldering defects, component misalignment, and missing parts with 99.8% accuracy. FCT conducts full functional testing on finished assemblies to verify whether their electrical performance meets design requirements, covering 100% of functional indicators.

- 5-Year Warranty Commitment: Our industry-leading 5-year warranty is a concrete reflection of our confidence in product quality, covering all quality issues caused by raw material defects, assembly errors, and performance failures during normal use. For Spanish clients, we provide localized after-sales support, with an after-sales response time within 2 hours and on-site maintenance service within 48 hours for major cities like Madrid and Barcelona, ensuring timely solutions to any quality problems during the warranty period.

- Compliance Verification: We implement strict compliance verification for every batch of PCB assemblies, tailored to Spain’s strict EU regulatory requirements. All products undergo professional testing to meet RoHS, REACH, and sector-specific standards including MDR 2017/745 for medical PCBA and EU automotive standards for automotive-grade assemblies. We provide detailed compliance test reports and certification documents for each order, with a compliance verification pass rate of 100%, helping clients smoothly pass EU market audits.

Our Spain PCB Assembly Capabilities

| Item | Capabilities |

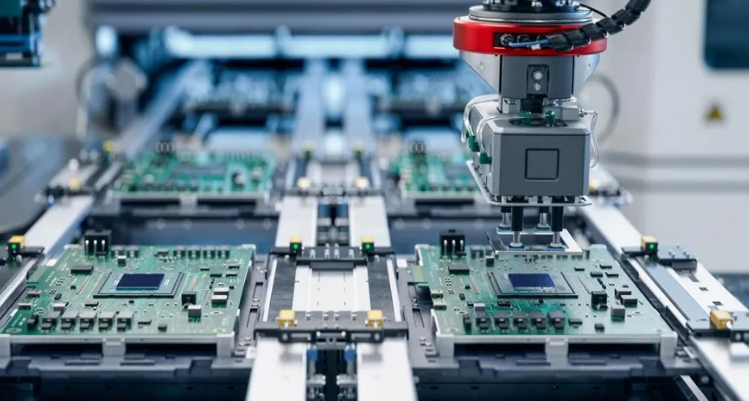

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

Case Studies of Our Spain Medical PCB Assembly

Project Background: A Spanish medical device manufacturer needed PCB assembly in Spain for their new portable patient monitor, a critical clinical and emergency device for tracking patient vital signs. It required strict EU MDR compliance, exceptional precision, and zero margin for error to safeguard patient safety.‚Äč

Requirements: The project required high-density SMT assembly with 0.1mm pitch components to fit the monitor’s compact design, a 99.9% yield rate, delivery within 12 working days for product launch, comprehensive MDR compliance documentation, and compatibility with the client’s existing design.

‚ÄčChallenges: Key challenges included strict MDR traceability documentation, shortages of medical-grade components (including critical high-precision sensors) in Spain, a tight 12-day delivery schedule, and zero tolerance for quality defects.‚Äč

Our Solution: We used our one-stop PCB assembly in Spain service to streamline processes, sourced medical-grade components from authorized EU suppliers, implemented our MES system for MDR traceability, optimized production with double shifts, and conducted pre-production DFM checks for high-density assembly feasibility.‚Äč

Output Results: We delivered 500 PCB assemblies in 10 working days (beating the 12-day target), achieved a 99.95% yield rate, and passed all EU MDR audits. The client successfully launched the monitor in Europe, with zero post-delivery defects over 6 months of clinical use.

FAQs About PCB Assembly Service in Spain

Q1: How can I ensure my PCB assembly in Spain meets EU RoHS and REACH regulations?

A1: Partner with a provider that sources RoHS/REACH-certified components, conducts pre-production compliance testing, and maintains detailed documentation. Our service includes full compliance verification and documentation to ensure your PCB assembly in Spain meets all EU regulatory requirements, with strict BOM sorting and targeted compliance detection to avoid non-compliance risks.

Q2: What can be done to avoid delays from component shortages in PCB assembly in Spain?

A2: Work with a provider with a global supply chain network and backup component stock. We maintain inventory of over 900 types of common components in Spain and partner with more than 200 authorized suppliers worldwide to quickly source hard-to-find parts, minimizing delays for your PCB assembly in Spain and ensuring production continuity.

Q3: What is the typical lead time for PCB assembly in Spain, and can it be expedited?

A3: Typical lead times range from 5-22 working days, depending on complexity and order size. Our one-stop service offers expedited options for urgent orders, with delivery within 24-48 hours for small batches and rapid prototyping, while maintaining our 99.2% on-time delivery rate for all PCB assembly in Spain projects.

Q4: How do you ensure high precision for complex PCB assembly in Spain?

A4: We use advanced SMT equipment with high placement accuracy (up to ¬Ī25őľm for micro-components) , implement in-process AOI/SPI testing, and conduct detailed pre-production checks. Our MES system tracks every step to ensure consistency, and our team has 20 years of experience in complex PCB assembly in Spain for medical and automotive sectors, with strict in-process quality control for solder paste printing and reflow soldering.

Q5: Is local PCB assembly in Spain more cost-effective than overseas options?

A5: While local labor costs are higher, PCB assembly in Spain reduces logistics costs, avoids customs delays, and ensures easier communication and regulatory compliance, lowering overall risk and total cost of ownership. Our global supply chain, centralized procurement and streamlined production processes balance cost and quality to provide competitive pricing for Spanish clients.

Tags: PCB assembly in Spain, PCB assembly service in Spain, PCB assembly Spain, Spain PCB Assembly