When seeking reliable prototyping services in the region, PCB prototype Australia stands as a critical link in electronic project advancement, with demands focusing on speed, precision and quality. Our PCB prototype Australia services are tailored to address the unique challenges of the local market, combining proven expertise and efficient delivery to support seamless project progression without unnecessary delays or compromises.

Top 10 PCB Factories for Prototype

| Company Name | Advantages | Prototyping Capability | Prototyping Lead Time |

| EBest Circuit Co., Limited | 19-year industry experience, multiple quality certifications, MES system for production tracking | 1-30 layers, HDI PCB, ceramic PCB, line width/spacing ‚ȧ40őľm, impedance control ¬Ī3% | Regular: 48-72 hours; Express: 24 hours |

| Alfatron Pty Ltd | Australian-owned family business since 1978, high confidentiality, rich testing capabilities | 1-12 layers, rigid-flex PCB, HDI, automated assembly and AOI/ICT testing | Regular: 3-5 days; Express: 48 hours |

| Allegro Services | 30+ years of local experience, full-process PCBA services, professional technical team | 1-60 layers, rigid PCB, SMT double-sided mounting, laser-guided assembly | Regular: 4-6 days; Express: 72 hours |

| 4 Volts Electronic Engineering Melbourne | Local Melbourne-based, fast response, suitable for small-batch prototypes | 1-8 layers, rigid PCB, FR-4 material, basic electrical testing | Regular: 5-7 days; Express: 48 hours |

| Artronic Australia Pty. Ltd | Cost-effective, flexible order terms, good after-sales service | 1-10 layers, rigid PCB, standard FR-4, surface treatment options (immersion gold, HAL) | Regular: 6-8 days; Express: 72 hours |

| B.E.C. Manufacturing Pty Ltd | Specializes in flexible and rigid PCB, diverse material options | 1-10 layers, flexible/rigid PCB, copper/FR-4/Teflon materials | Regular: 4-7 days; Express: 5 days |

| Broad Avenue Industries Pty Ltd | ISO 9001 certified, supports HDI and hybrid PCB, UL certified | 1-10 layers, HDI, hybrid PCB, aluminum/copper substrates | Regular: 3-6 days; Express: 48 hours |

| Circuitwise Australia | Focus on medical and aerospace PCB, strict quality control, compliance with international standards | 1-16 layers, HDI, ceramic PCB, medical-grade material and testing | Regular: 5-8 days; Express: 72 hours |

| PCB Solutions Australia | Online quoting system, fast file review, transparent production process | 1-12 layers, rigid PCB, impedance control, basic AOI testing | Regular: 4-6 days; Express: 48 hours |

| Melbourne PCB Co. | Local production, short delivery distance, customized prototype solutions | 1-8 layers, rigid PCB, FR-4 halogen-free, small-size prototype support (6*6mm) | Regular: 5-7 days; Express: 72 hours |

Pain Points of Australia Prototype PCB

- Is it hard to find PCB prototype Australia services that offer 24-hour express delivery for urgent projects?‚Äč

- Does PCB prototype Australia often have high costs for small-batch or complex prototypes like HDI boards?‚Äč

- Can most PCB prototype Australia providers meet the strict quality requirements of medical electronic products?‚Äč

- Is it difficult to track the real-time production progress of PCB prototype Australia orders?‚Äč

- Do many PCB prototype Australia factories lack the capability to produce special substrates like ceramic PCB?‚Äč

- Is the minimum order quantity of most PCB prototype Australia services too restrictive for small-scale experiments?‚Äč

- Do PCB prototype Australia providers often have long lead times for complex multi-layer (16+ layers) prototypes?

Why Choose EBest(Best Technology) for PCB Prototype Australia?

Reasons Why Choose EBest( Best Technology) for PCB Prototype Australia:

- Expedited Service: We offer 24-hour fast prototyping and delivery, solving the urgent project needs that many providers cannot meet.

- Rich Experience: 19 years of PCB production experience, serving 5000+ global clients, with mature technology to reduce production costs and our small-batch prototype prices are 15% lower than the local Australian average.

- Strong Process Capability: We specialize in HDI PCB (line width/spacing ‚ȧ30őľm) and ceramic PCB (alumina/aluminum nitride substrates), covering the special substrate needs that many factories lack.

- Strict Quality Control: Certified by ISO9001, AS9100D, and IATF 16949, with 3 rounds of testing (AOI, X-ray, electrical testing) to ensure a prototype qualification rate of 99.8%.

- Free DFM Service: We provide free Design for Manufacturability (DFM) reviews to identify potential design issues in advance, helping avoid production delays, rework costs and ensure smooth manufacturing processes.

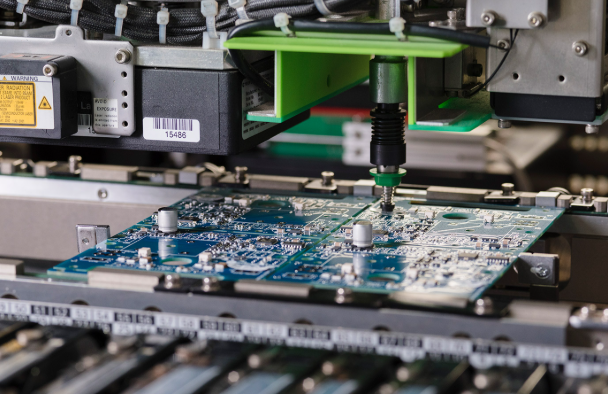

- Full-Service Support: We provide one-stop PCBA services, integrating prototype, assembly, and testing, saving time and costs for clients.

- Transparent Production: Equipped with MES production management system, all production data is traceable, allowing real-time query of order progress.

- Flexible MOQ: Minimum order quantity of 1 piece, fully adapting to small-scale experiment needs, solving the MOQ restriction problem of most services.

Types of PCB Prototype Australia We Can Offer

- Rigid PCB Prototype: 1-30 layers, FR-4, FR-4 halogen-free, high Tg materials, suitable for most electronic products.

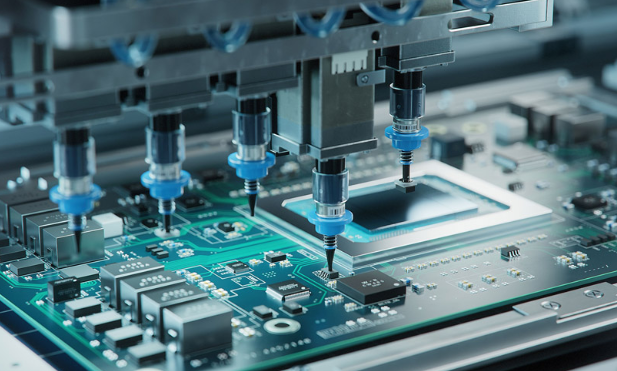

- HDI PCB Prototype: 2-20 layers, blind/buried vias, line width/spacing ‚ȧ30őľm, for high-density electronic devices.

- Ceramic PCB Prototype: Alumina (24-28 W/mK) and aluminum nitride (170-230 W/mK) substrates, for high-temperature and high-power scenarios.

- Flexible & Rigid-Flex PCB Prototype: 1-12 layers, laser microvias, adaptable to small or irregular installation spaces.

- Metal Core PCB Prototype: Aluminum/copper substrates, thermal conductivity up to 380 W/mK, for LED and high-power electronic products.

- Impedance Controlled PCB Prototype: Impedance tolerance ¬Ī3%, suitable for high-frequency signal transmission (insertion loss <0.3 dB/inch @28 GHz).

Quality Standards for PCB Prototype Australia

- Raw Material Standard: All substrates (FR-4, ceramic, metal) comply with IPC standards, with 100% supplier qualification checks and batch testing to ensure consistency.‚Äč

- Process Standard: Adhere strictly to ISO9001, AS9100D, and IATF 16949 certifications, using laser direct imaging (LDI) technology to guarantee process precision.‚Äč

- Testing Standard: Conduct AOI inspection (¬Ī12őľm accuracy), X-ray testing for blind/buried vias, 10V-250V electrical testing, and thermal stress simulation to eliminate defects.‚Äč

- Impedance Standard: Maintain ¬Ī3% impedance control for high-frequency prototypes, with dynamic calibration throughout the design-to-production process.‚Äč

- Surface Treatment Standard: Offer immersion gold (20-30őľm), lead-free HAL, and chemical tin options, all fully compliant with RoHS standards.‚Äč

- Dimensional Standard: Ensure board thickness tolerance ¬Ī0.1mm, minimum drilled hole size 0.25mm, and line width/spacing tolerance ¬Ī0.075mm.

Lead Time for Prototype PCB Australia

| Layers | Normal Service | Fastest Service |

| 1 | 7 Days | 24 H |

| 2 | 8 Days | 24 H |

| 4 | 10 Days | 48 H |

| 6 | 10 Days | 72 H |

| 8 | 12 Days | 72 H |

| ‚Č•10 | TBD | TBD |

Case Studies of Medical PCB Prototype Australia

Project Background

A Melbourne-based Australian medical device company specializes in the R&D and production of portable patient monitors. They needed a high-reliability PCB prototype for a new generation of monitors, which required strict compliance with medical industry standards and urgent delivery to meet their product launch schedule.

Project Requirements

- Prototype Type: 8-layer HDI PCB, line width/spacing 40őľm/40őľm, impedance control ¬Ī5%.

- Material: FR-4 halogen-free (high Tg 170‚ĄÉ), meeting medical biocompatibility standards.

- Quality: Compliance with ISO 13485 and IPC Class 3, 100% electrical testing and AOI inspection.

- Lead Time: Total delivery within 3 days (urgent project launch demand).

Project Challenges

- Tight Lead Time: Most PCB prototype Australia providers require 4-6 days for 8-layer HDI prototypes, failing to meet the 3-day deadline.

- Strict Quality: Medical-grade PCB requires zero defects, with higher testing standards than ordinary industrial prototypes.

- Precision Requirements: HDI structure with tight line width/spacing and impedance control, requiring high-precision production equipment.

Our Solutions

- Urgent Production Arrangement: Activated our 24-hour express production line, assigning 3 dedicated technicians to the project to shorten production time.

- Quality Control Enhancement: Added a pre-production design review (DFM) to avoid design errors, and adopted dual AOI testing (pre and post-soldermask) to ensure zero defects.

- Precision Process Control: Used laser direct imaging (LDI) technology and automated impedance testing to ensure the line width and impedance accuracy meet requirements.

Output Results

- Delivery: Completed production and testing in 2.5 days, delivered 1 day ahead of the client’s deadline.

- Yield Rate: 99.9% prototype qualification rate, with zero defects in electrical and visual testing.

- Client Feedback: ‚ÄúThe prototype quality exceeds our expectations, and the fast delivery helps us launch the new product on schedule. We will continue to cooperate with you for all our PCB prototype Australia needs.‚ÄĚ

FAQs of PCB Prototype Service Australia

Q1: How to solve the problem of long lead times for complex prototype orders?‚Äč

A1: We specialize in solving urgent prototype needs with our 24-hour express service for simple boards and 48-72 hours for complex multi-layer or HDI boards. Unlike ordinary providers, we optimize production processes and activate dedicated production lines exclusively for your orders, cutting lead times by 50% while maintaining strict quality control. Our efficient workflow ensures you get high-quality prototypes on time, every time.‚Äč

‚Äč

Q2: Can your prototype services meet the quality standards of medical equipment?‚Äč

A2: Absolutely. We hold strict certifications including ISO 13485, ISO 9001 and AS9100D, specifically tailored to meet the rigorous requirements of medical equipment production. We select only medical-grade raw materials and conduct triple testing (AOI, X-ray, electrical testing) to ensure zero defects. With a 99.8% medical PCB prototype qualification rate, we are the trusted choice for medical equipment-related prototype needs.‚Äč

‚Äč

Q3: What if I need a small batch (1-5 pieces) of ceramic PCB prototypes, which most factories do not support?‚Äč

A3: We excel at fulfilling small-batch prototype needs, with a minimum order quantity (MOQ) of 1 piece for all prototype types, including ceramic PCBs. We own specialized ceramic substrate production equipment and have rich experience in manufacturing ceramic prototypes, so you won‚Äôt incur extra costs for small orders. We eliminate the restrictions that most providers impose, making it easy for you to complete small-scale experiments or R&D projects.‚Äč

‚Äč

Q4: How can I track the real-time production progress of my prototype order?‚Äč

A4: We provide a dedicated, user-friendly order tracking system directly linked to our MES production management system. Once you place an order, you‚Äôll receive a unique tracking link that lets you check every stage of production in real time from design review and manufacturing to testing and shipping. Data is updated every 2 hours, giving you full transparency and peace of mind, so you never have to wonder about your order‚Äôs status.‚Äč

‚Äč

Q5: How do you help avoid design errors that lead to production delays or rework?‚Äč

A5: We offer a free Design for Manufacturability (DFM) review service, an exclusive advantage that sets us apart from other providers. Our professional technical team will carefully review your design files in advance, identifying potential issues that could cause delays or rework. We provide detailed optimization suggestions to ensure your design is production-ready, saving you time, reducing hassle, and ensuring a smooth, efficient prototype production process.

Tags: Australia prototype PCB, PCB Prototype Australia, PCB prototype service Australia, prototype PCB assembly Australia, prototype PCB Australia