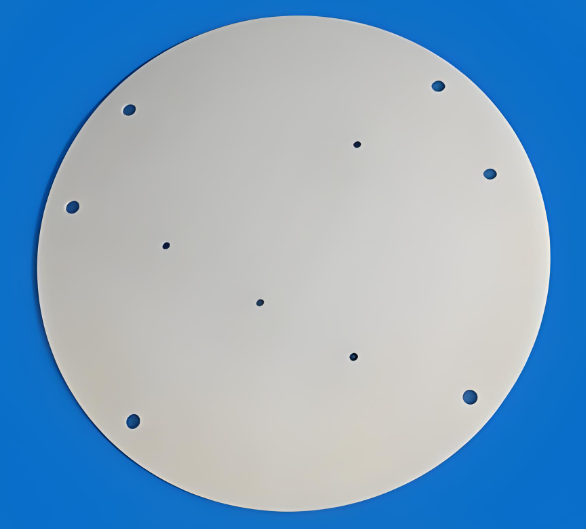

What Is an Alumina Substrate?

An alumina ceramic substrate is a rigid ceramic base material primarily composed of aluminum oxide (Al₂O₃), used as a carrier for electronic circuits in environments where heat, voltage, and mechanical stress exceed the limits of organic PCB materials. Unlike FR-4 or metal-core laminates, alumina substrates are inorganic, dense, and dimensionally stable, which makes them suitable for long-life and high-reliability electronics.

In practical terms, an alumina substrate serves three roles at the same time. It electrically isolates conductive layers, mechanically supports components, and manages heat generated during operation. This multifunctional nature is the main reason alumina ceramic substrates are widely adopted in power electronics, LED modules, and industrial control systems.

Alumina Substrate Thickness

Thickness selection is one of the most underestimated design decisions for an alumina ceramic substrate, yet it directly affects mechanical strength, thermal behavior, and assembly yield.

Common thickness ranges include:

- 0.25–0.38 mm for compact, low-stress designs

- 0.50–0.63 mm for standard LED and power control circuits

- 0.80–1.00 mm for high-mechanical-stress or high-voltage applications

Thinner substrates improve heat transfer but are more vulnerable to cracking during soldering or handling. Thicker substrates provide better rigidity but may introduce thermal resistance. The correct thickness depends on component size, copper loading, and thermal cycling conditions rather than on cost alone.

What Temperature Does Alumina Ceramic Fire At?

Alumina ceramics are manufactured through a high-temperature sintering process. Depending on purity and formulation, alumina ceramic substrates are typically fired at temperatures between 1,600°C and 1,750°C.

This firing process is what gives alumina its density, mechanical strength, and thermal stability. Because the substrate has already been exposed to extreme temperatures during manufacturing, it remains stable during electronic assembly processes such as lead-free reflow soldering.

Types of Alumina Ceramic Substrate

Alumina ceramic substrates can be categorized based on purity, surface finish, and metallization compatibility.

96% Alumina Ceramic Substrate

This is the most widely used grade in electronics manufacturing.

Key characteristics:

- Balanced thermal conductivity and mechanical strength

- Stable dielectric performance for industrial voltages

- Mature supply chain and predictable quality

Typical use cases include LED modules, power control boards, automotive electronics, and industrial interfaces where operating conditions are well understood and cost control is important.

99% Alumina Ceramic Substrate

Higher purity alumina is used when tighter performance margins are required.

Key characteristics:

- Improved thermal stability at elevated temperatures

- Lower dielectric loss for high-frequency signals

- Better material consistency for precision applications

This grade is often selected for RF circuits, high-temperature sensors, and applications with strict electrical performance requirements. However, it should be chosen based on actual need rather than assumed superiority.

96% vs 99% Alumina Ceramic Substrate: How to Choose the Right Grade?

96% Alumina Ceramic Substrate

96% alumina is the most widely used grade in industrial electronics.

Its advantages include:

- Excellent cost-to-performance ratio

- Good mechanical strength

- Sufficient thermal conductivity for most power and LED designs

For high-volume products with controlled operating conditions, 96% alumina is usually the most practical choice.

99% Alumina Ceramic Substrate

99% alumina offers higher purity and tighter material consistency.

It is typically chosen for:

- High-temperature environments

- RF and high-frequency circuits

- Applications requiring lower dielectric loss

However, higher purity does not automatically mean better reliability. Using 99% alumina where it is not required increases material cost without solving real design risks.

Metallization Options for Alumina Ceramic Substrate (Thick Film, DBC, AMB)

Metallization defines how copper or conductive layers bond to the alumina surface, and it has a direct impact on current capacity and long-term reliability.

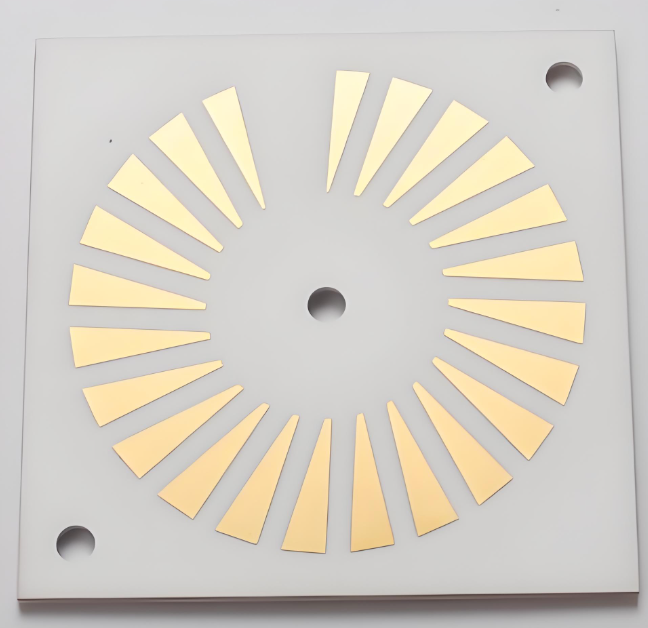

Thick Film Metallization

Thick film metallization uses screen-printed conductive pastes.

It is suitable for:

- Low to medium current circuits

- Cost-sensitive designs

- Mature, proven manufacturing processes

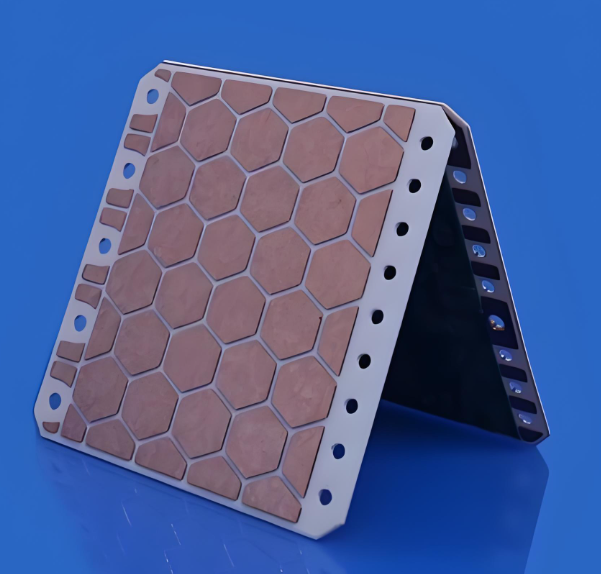

Direct Bonded Copper (DBC)

DBC bonds solid copper sheets directly to the alumina substrate.

It supports:

- High current density

- Excellent thermal conduction

- Power modules and converters

Active Metal Brazing (AMB)

AMB uses a reactive bonding layer to improve adhesion.

It offers:

- Strong copper-to-ceramic bonding

- Better resistance to thermal cycling

- Higher reliability for demanding applications

Choosing metallization based solely on price is a common mistake that leads to premature field failures.

Why Engineers Choose Alumina Ceramic Substrate for Power and LED Applications?

Engineers select alumina ceramic substrate solutions when performance stability matters more than short-term savings.

Key reasons include:

- Reliable electrical insulation at high voltage

- Stable thermal behavior under continuous load

- Compatibility with automated assembly

- Proven performance across decades of use

In LED lighting, alumina substrates help control junction temperature and extend lumen lifetime. In power electronics, they isolate high voltage while maintaining mechanical integrity under thermal cycling.

Alumina Ceramic Substrate vs AlN vs BeO: Detailed Comparison

| Parameter | Alumina Ceramic Substrate (Al₂O₃) | Aluminum Nitride (AlN) | Beryllium Oxide (BeO) |

| Typical Purity | 96% / 99% | ≥ 95% | ≥ 99% |

| Thermal Conductivity (W/m·K) | 20–30 | 150–180 | 250–330 |

| Dielectric Strength (kV/mm) | 10–15 | 12–15 | 10–12 |

| Dielectric Constant (εr @ 1 MHz) | 9.4–9.9 | 8.5–9.0 | 6.5–7.0 |

| Dielectric Loss (tan δ) | ~0.0002–0.0004 | ~0.0001 | ~0.0001 |

| Coefficient of Thermal Expansion (CTE, ppm/°C) | 6.5–7.5 | 4.5–5.0 | 7.0–8.0 |

| Flexural Strength (MPa) | 300–400 | 300–350 | 200–300 |

| Operating Temperature (°C) | Up to 1,000 | Up to 1,200 | Up to 1,400 |

| Common Thickness Range (mm) | 0.25–1.0 | 0.25–0.63 | 0.25–0.63 |

| Metallization Compatibility | Thick Film, DBC, AMB | DBC, AMB | DBC, AMB |

| Moisture Sensitivity | Very Low | Moderate (hydrolysis risk) | Very Low |

| Health & Safety Risk | None | Low | High (toxic dust) |

| Regulatory Restrictions | None | None | Strict (OSHA, EU) |

| Material Cost Index* | 1.0 (baseline) | 4–6× alumina | 8–12× alumina |

| Supply Chain Maturity | Very High | Medium | Very Limited |

| Mass Production Suitability | Excellent | Moderate | Poor |

| Typical Lead Time | Short | Medium | Long |

While AlN and BeO offer superior thermal conductivity, alumina remains the most balanced solution for cost, safety, and scalability.

Why Alumina Ceramic Substrate Fails During Assembly—and How to Prevent It?

Most alumina substrate failures occur during assembly rather than during operation.

Common causes include:

- Excessive thermal shock during reflow

- Poor copper layout causing stress concentration

- Mismatch between solder alloy and metallization

Preventive measures involve controlled heating profiles, balanced copper distribution, and assembly-aware design decisions. Addressing these factors early prevents costly redesigns later.

What Is Alumina Ceramic Used For?

Alumina ceramic substrates are used in a wide range of electronic and industrial applications, including:

- Power converters and inverters

- LED lighting modules

- Automotive electronics

- Industrial control systems

- Sensor and actuator circuits

These applications demand durability, electrical insulation, and predictable thermal behavior over long service lives.

Is Alumina Ceramic Better Than Zirconia Ceramic?

Alumina and zirconia ceramics serve different purposes.

Alumina is preferred when:

- Electrical insulation is critical

- Thermal stability is required

- Cost control matters

Zirconia is chosen for:

- High mechanical toughness

- Structural or wear-resistant components

For electronic substrates, alumina remains the more suitable and economical choice.

FAQs

1. What thickness should I choose for an alumina ceramic substrate?

Thickness depends on mechanical stress, copper loading, and thermal requirements. Most electronic designs use 0.38–1.0 mm.

2. Can alumina ceramic substrate handle lead-free soldering?

Yes. Alumina remains stable at lead-free reflow temperatures when properly designed.

3. Why does copper delaminate from alumina substrates?

Delamination is usually caused by incorrect metallization selection or excessive thermal stress during assembly.

4. Is alumina ceramic substrate suitable for mass production?

Yes. Its mature manufacturing processes make it ideal for scalable, high-volume production.

5. When should I consider alternatives like AlN?

AlN is recommended only when heat density exceeds alumina’s practical limits.