What is the best flux for soldering? This blog covers benefits, composition, types and selection guide, shelf life, usage instructions for soldering flux.

Are you troubled soldering with these issues?

- Persistent post-soldering cold joints/dry joints leading to high batch rework costs?

- Solder joint oxidation and insufficient wetting forcing compromises on product reliability?

- Frequent incomplete solder connections disrupting production schedules unexpectedly?

As a PCBA service supplier, EBest Circuit (Best Technology) can provide you service and solutions:

- Superior electrical connection performance: precise full-process control ensures stable conductivity and low resistance in solder joints.

- Reliable mechanical connection strength: empowered by process expertise, solder joints withstand vibration and impact, extending product lifespan.

- Leading first-pass yield: optimized materials and parameters minimize rework, ensuring efficiency and cost advantages.

Welcome to contact us if you have any request for PCBA service: sales@bestpcbs.com.

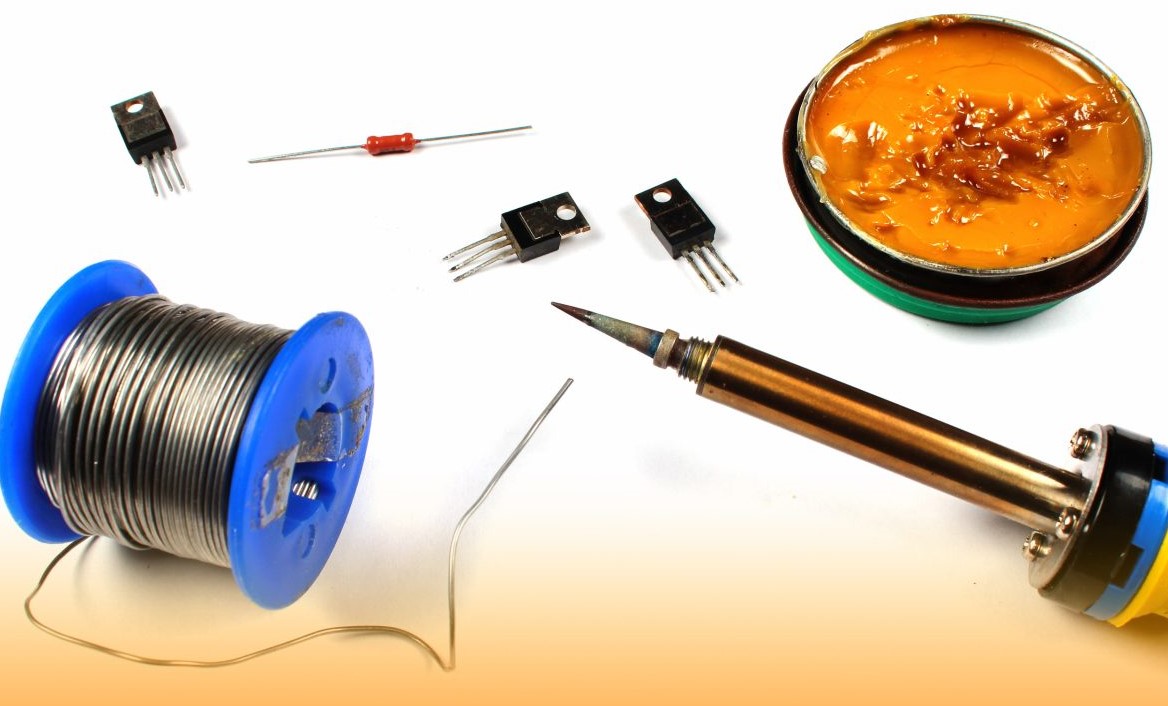

What Is Flux for Soldering?

Soldering flux is an essential chemical agent in the welding process. Its core function is to help molten solder flow better, wet, and adhere firmly to the metal surface to be welded. To achieve this, flux mainly performs two key functions: firstly, it removes impurities such as oxides and oil from the metal surface (these impurities hinder the direct bonding between the solder and the metal substrate); secondly, it reduces the surface tension of the molten solder, allowing it to spread more evenly and smoothly at the solder joint, forming a reliable electrical and mechanical connection. Therefore, flux is crucial for ensuring welding quality and reducing cold and incomplete welds. Common types include rosin-based, no-clean, and water-soluble fluxes.

What Is Flux for Soldering Made of?

- Base Material (Matrix): Usually rosin (natural or modified resin) or synthetic resin. They provide the basic carrier, possess a certain degree of deoxidizing ability, and may form a protective layer after soldering (e.g., rosin-based fluxes).

- Activators: It is used to powerfully remove oxides and contaminants from metal surfaces. Common examples include:

- Organic Acids: Such as lactic acid, citric acid, stearic acid, etc. (often used in water-soluble or no-rinse fluxes).

- Organic Amine Hydrochlorides: Such as diethylamine hydrochloride (highly reactive).

- Halide Compounds: Such as bromides, chlorides (the most reactive, but also highly corrosive, requiring post-treatment).

- Solvents: Used to dissolve the activators and resins, and to adjust the viscosity, volatility, and coating properties of the flux. Commonly used are alcohols (such as isopropanol, ethanol), alcohol ethers, or water (for water-soluble fluxes). Additives:

- Corrosion Inhibitors: Neutralize residual surfactants and reduce corrosivity (especially important in no-clean fluxes).

- Surfactants: Further reduce solder surface tension and enhance wetting and spreading ability.

- Stabilizers/Antioxidants: Maintain flux performance stability and prevent deterioration.

What Is the Best Flux for Soldering?

Soldering Flux Selection Guideline in Different Scenarios:

1. Electronic Repair Scenario

- Recommended Type: Rosin-based flux (e.g., RMA grade) or no-clean flux

- Advantages: Rosin-based flux has strong oxidation removal ability, minimal residue, and easy cleaning, suitable for manual soldering. No-clean flux eliminates post-welding cleaning, saving time, ideal for automated repair.

- Operation Precautions: Control rosin-based flux usage (excess may cause residue); clean with alcohol after soldering. No-clean flux should avoid mixing with acidic flux; store sealed, away from light (temperature <30°C, humidity <75%).

2. Industrial Production Scenario

- Recommended Type: Water-soluble flux (for wave soldering) or synthetic resin-based flux (for SMT/BGA packaging)

- Advantages: Water-soluble flux is eco-friendly and easy to clean, ideal for high-density PCBs. Synthetic resin-based flux withstands high temperatures, compatible with SMT processes, with low residue and conductivity.

- Operation Precautions: Water-soluble flux requires dedicated cleaning agents; avoid mixing with strong acids. Synthetic resin-based flux needs temperature control (240-260°C) to prevent carbonization.

3. Precision Instrument Scenario

- Recommended Type: Low-activity halogen-free flux (e.g., ROL0 grade) or high-frequency dedicated flux

- Advantages: Low-activity flux has weak corrosion, suitable for fine-pitch components (e.g., chips). High-frequency flux has low dielectric loss (≤0.002 at 10GHz), avoiding signal attenuation.

- Operation Precautions: Test via “spread rate” and “wetting time” (GB/T 9491-2021); avoid conductive residue; store away from fire sources.

4. Automotive Electronics Scenario

- Recommended Type: Enhanced-activity flux (e.g., for SnAgCu solder balls)

- Advantages: Suitable for high-power PCBs (copper thickness 105μm), with solder joint tensile strength ≥8N, temperature resistance (-40°C~125°C), and passes thermal cycle tests (1000 cycles without cracking).

- Operation Precautions: Control preheating temperature (85-120°C); avoid solder splashing; thoroughly clean residues post-welding.

5. High-Frequency/5G Scenario

- Recommended Type: High-frequency RMA-grade flux

- Advantages: Dielectric loss ≤0.002 at 10GHz, signal attenuation ≤0.2dB/m, no conductive residue, compatible with 5G base station PCBs.

- Operation Precautions: Avoid reaction with solder mask inks; test impedance changes (±1% tolerance) post-welding; store in moisture-proof and oxidation-proof conditions.

6. General Operation Precautions

- Storage: Sealed, cool, ventilated (18-25°C), away from fire sources and acidic/alkaline substances; avoid direct sunlight.

- Usage Environment: Well-ventilated area; wear protective gear (mask, gloves, goggles); use dedicated exhaust systems.

- Process Control: Apply flux evenly; control soldering temperature and time (e.g., wave soldering preheat 75-120°C); clean equipment regularly to prevent clogging.

- Safety: Rinse skin with soap water if contacted; seek medical attention if ingested; use CO₂ or dry powder fire extinguishers for fires.

7. Selection Principles

- Match Materials and Processes: Select flux type based on metal type (copper/aluminum) and soldering method (manual/wave/reflow). Rosin-based for electronic assembly, water-soluble for precision cleaning.

- Cleaning Requirements: Choose soluble types (water-soluble) for cleaning-needed scenarios; low-residue formulas for no-clean scenarios.

- Activity Evaluation: High-activity (inorganic acid) for severe oxidation; low-activity (organic acid/rosin) for precision scenarios.

- Environmental and Safety Standards: Prioritize lead-free, halogen-free, low-VOC products; comply with RoHS and pass tests like “copper mirror corrosion” and “surface insulation resistance”.

- Testing and Validation: Evaluate performance (wetting, residue, corrosion) via small-batch tests; ensure compatibility with actual processes (e.g., IPC-SP-800 standard).

Why Using Flux in Soldering?

- Remove Metal Surface Oxides: Flux active ingredients (rosin, organic acids) dissolve metal oxides (e.g., copper oxide) via chemical reactions, exposing clean metal substrates for proper solder wetting. Unremoved oxides cause poor solder adhesion, leading to cold solder joints or incomplete soldering.

- Prevent Secondary Oxidation During Soldering: At high temperatures, flux forms a protective film (e.g., rosin layer) that isolates metal surfaces from oxygen, inhibiting new oxide formation and maintaining clean metal surfaces throughout the soldering process.

- Reduce Solder Surface Tension for Improved Wetting: Surfactants in flux lower solder surface tension, enabling liquid solder to spread and penetrate base metals more effectively. For example, rosin flux reduces solder contact angles from 70°-90° to 20°-40°, ensuring uniform solder coverage without voids.

- Enhance Mechanical Strength and Conductivity: By removing oxides and improving wetting, flux facilitates the formation of strong intermetallic compounds (e.g., Cu?Sn?), increasing joint shear strength and fatigue resistance while reducing electrical resistance for reliable conductivity.

- Minimize Welding Defects and Boost Yield: Flux prevents common defects such as bridging, pinholes, and cracks. In wave soldering, it reduces solder bridging between adjacent pads; in manual soldering, it avoids joint fractures from poor wetting. Proper flux use can increase soldering pass rates by 20%-30%.

- Adapt to Process and Material Requirements: Flux formulations are tailored for specific processes (manual, reflow, wave soldering) and materials (copper, aluminum, stainless steel). High-activity fluxes are used for aluminum to break dense oxides; low-residue fluxes meet lead-free and high-frequency circuit needs.

- Shield Soldering Areas from Contamination: Flux creates a temporary protective barrier that blocks dust, grease, and other contaminants from entering solder joints, maintaining cleanliness in precision electronics like chip packaging to prevent short circuits or performance degradation.

Where Should Flux Be Applied When Soldering?

During soldering, flux should be evenly applied to the metal surfaces to be soldered (such as pads, leads, wire connectors, or pipe connections). Its function is to remove the metal oxide layer, reduce surface tension, and prevent secondary oxidation, thereby ensuring that the solder (such as solder) can fully wet and form a reliable metallurgical bond. In practical applications, it is necessary to cover the entire soldering area to avoid localized omissions that could lead to cold solder joints or oxidation problems. Especially in electronic soldering, the amount of flux used must be precisely controlled to prevent excessive residue from causing corrosion or short circuit risks.

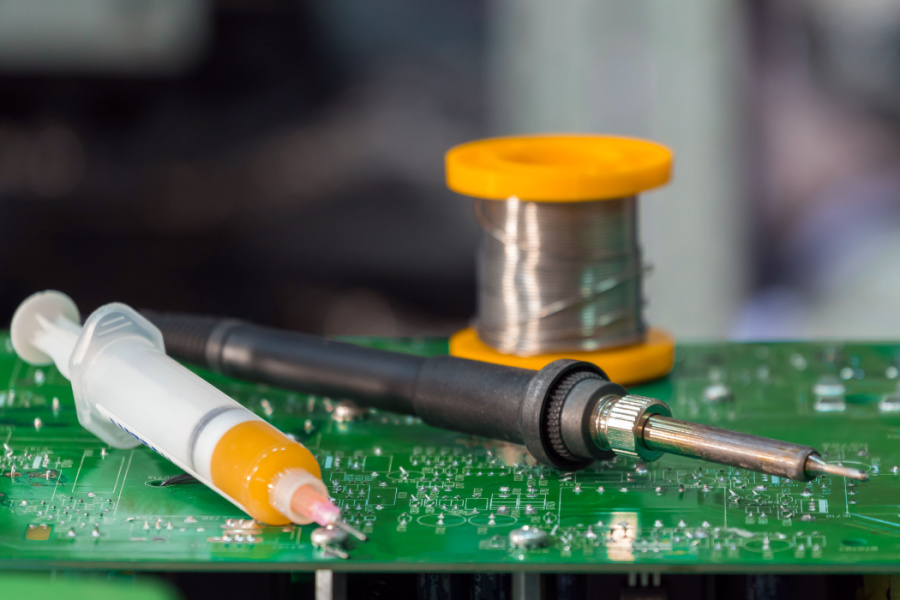

How Do you Apply Flux Solder Correctly?

1. Preparation and Substrate Cleaning Before Soldering

- Tool and Material Selection: Select the appropriate flux type based on the soldering material (e.g., copper, gold, lead, zinc-plated layers). For example, rosin-based flux is suitable for electronic circuit soldering, acidic flux for hard-to-solder materials like zinc/nickel alloys, and VOC-free no-clean flux for lead-free solder.

- Substrate Pre-treatment: Thoroughly wipe the soldering surface with alcohol or specialized cleaning agents to remove grease, oxides, and contaminants. Aluminum soldering requires pre-treatment with aluminum flux to ensure an oxide-free surface.

- Tool Inspection: Ensure the soldering iron is clean, with the tip pre-tinned. For wave soldering equipment, check the spray system, foaming device, and temperature control module for blockages or leaks.

2. Flux Application and Activation

- Manual Soldering: Apply flux evenly to solder points/pads using a brush, dropper, or dispensing syringe, avoiding excess to prevent corrosive residues.

- Wave/Selective Soldering: Use spray, foaming, or dipping systems for quantitative application. Control spray pressure (recommended 2-4 bar) and application volume (25-55 ml/min for single-sided boards, 35-65 ml/min for double-sided boards).

- Activation Conditions: Flux activates at soldering temperatures (typically 180-250°C), decomposing to remove oxides and promote solder wetting. Acidic flux requires complete evaporation at high temperatures to prevent residual corrosion.

3. Soldering Process Control

Temperature Management:

- Soldering iron temperature should match the solder type (e.g., 230-250°C for tin-lead solder, 260-300°C for lead-free solder). Excessive heat causes over-decomposition of flux; insufficient heat fails activation.

- Preheat temperature for wave soldering should align with substrate thickness (75-105°C for single-sided, 85-120°C for double-sided boards) to avoid thermal stress-induced component damage.

Soldering Techniques:

- Manual soldering requires full contact between solder, flux, and substrate to form a triangular wetting zone, ensuring smooth, void-free solder joints.

- Wave soldering requires adjusting wave height (3-5 mm) and conveyor speed (1-3 m/min) to prevent bridging or cold soldering.

- Special Processes: Selective soldering uses wettable nozzles (e.g., titanium alloy) with nitrogen shielding to reduce oxidation, paired with de-bridging devices to eliminate electrical bridges.

4. Post-Soldering Cleaning and Maintenance

Residue Treatment:

- Traditional flux requires thorough cleaning with isopropanol or specialized cleaning agents to prevent corrosion. No-clean flux may skip cleaning but must comply with international standards (e.g., ISO 12224-2).

- Wave soldering equipment needs regular cleaning of solder pots, nozzles, and filters to prevent flux residue buildup. Weekly cleaning and replacement of sediment flux in sealed tanks are recommended.

Safety and Storage:

- Flux is flammable; store in a cool, ventilated area (18-25°C) away from sunlight and heat.

- Operators must wear protective gear (gloves, goggles) to avoid inhalation or skin contact.

5. Quality Control and Standard Compliance

- International Standards: Adhere to ISO 12224-2 (flux content testing), IPC-TM-650 (solder joint wetting tests), and other norms to meet global quality requirements.

- Process Monitoring: Regularly test flux specific gravity, acidity, and fume levels for batch consistency. Wave soldering requires monitoring wave temperature, conveyor speed, and application volume, with data logging to optimize parameters.

- Troubleshooting: Address issues like cold soldering, bridging, or corrosion by verifying flux compatibility, uniform application, and accurate temperature control. Adjust processes or replace flux as needed.

How Do I Know If I Soldered Correctly?

1. Visual Inspection of Solder Joint Appearance

- Solder joints should exhibit a smooth, shiny conical or crescent shape with no cracks, pinholes, or uneven surfaces.

- Solder should uniformly coat the pad and component lead, showing no signs of cold solder joints (incompletely melted solder), bridges (short circuits between adjacent joints), or dry joints (insufficient bonding between solder and metal surfaces).

- Solder joint color should be silvery-gray or light yellow (for tin-lead solder), free from oxidation or scorch marks.

2. Electrical Connection Testing

- Use a multimeter to measure the resistance of solder joints, ensuring it meets circuit design requirements (typically low resistance indicates a good connection).

- Verify circuit functionality through operational tests, such as LED illumination, correct signal output from chips, etc.

- For suspicious joints, use a jumper wire to test continuity or employ a magnifying glass to inspect for micro-cracks.

3. Mechanical Strength Verification

- Apply gentle tension or rocking motion to the joint to check for firmness (avoid excessive force that may cause damage).

- For critical connections (e.g., power interfaces, high-current paths), conduct vibration or thermal cycling tests to simulate real-world conditions.

- Solder joints should withstand moderate bending or impact without detaching.

4. Professional Standards and Tool Assistance

- Refer to international standards like IPC-A-610 (Electronic Assembly Acceptability) to classify solder joints (e.g., Grade 1, 2, 3) against compliance criteria.

- Use a magnifying glass or microscope to examine solder joint details, such as solder wetting angle and pad integrity.

- Leverage X-ray inspection (for hidden joints like BGAs) or AOI (Automated Optical Inspection) equipment for non-destructive evaluation.

5. Common Issue Troubleshooting

- Cold Solder Joint: Solder not fully melted, resulting in a rough, matte surface; repairable by reheating.

- Dry Joint: Insufficient bonding between solder and metal surface; verify by scratching the joint surface and re-soldering.

- Bridging: Excess solder causing short circuits between adjacent joints; remove excess solder using solder wick or a soldering iron.

- Pad Lift: Excessive heat causing pad detachment; reattach the lead and repair the pad.

What Is the Shelf Life of Soldering Flux?

The shelf life of soldering flux is typically 1 to 3 years in its unopened state, depending on its chemical composition (such as rosin-based, no-clean, water-soluble, etc.), packaging seal, and storage conditions (cool and dark). After opening, its effectiveness and performance (especially flux activity and anti-oxidation ability) will gradually decrease due to solvent evaporation and possible degradation or reaction of active ingredients with air. It is recommended to use it up within 6 months to 1 year after opening and to store it in a strictly sealed container. If the flux is found to have layered, discolored, crystallized, or has abnormal viscosity, it indicates that it has deteriorated and become ineffective. Continued use may lead to poor soldering or corrosion risks.

Tags: Flux for Soldering, Soldering flux