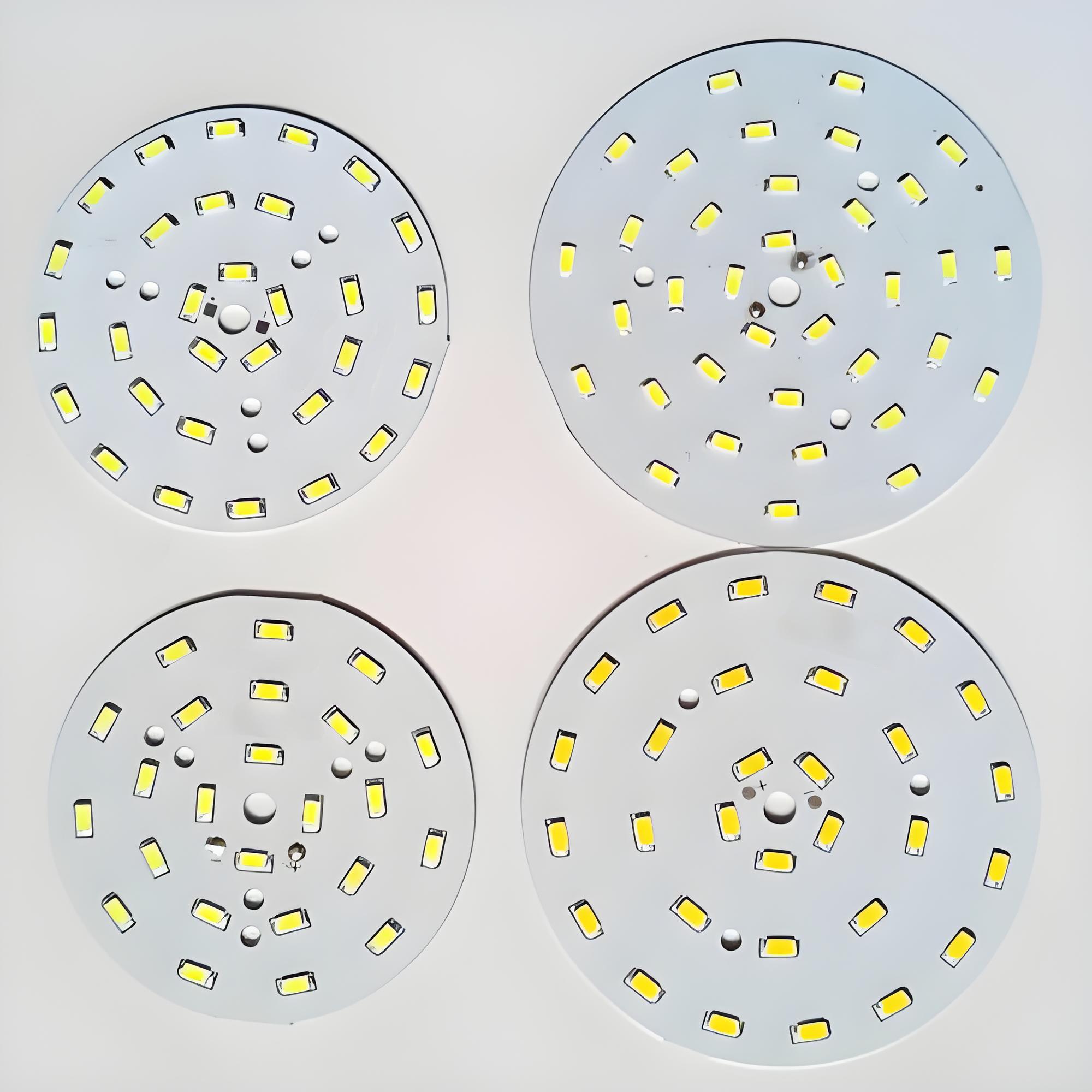

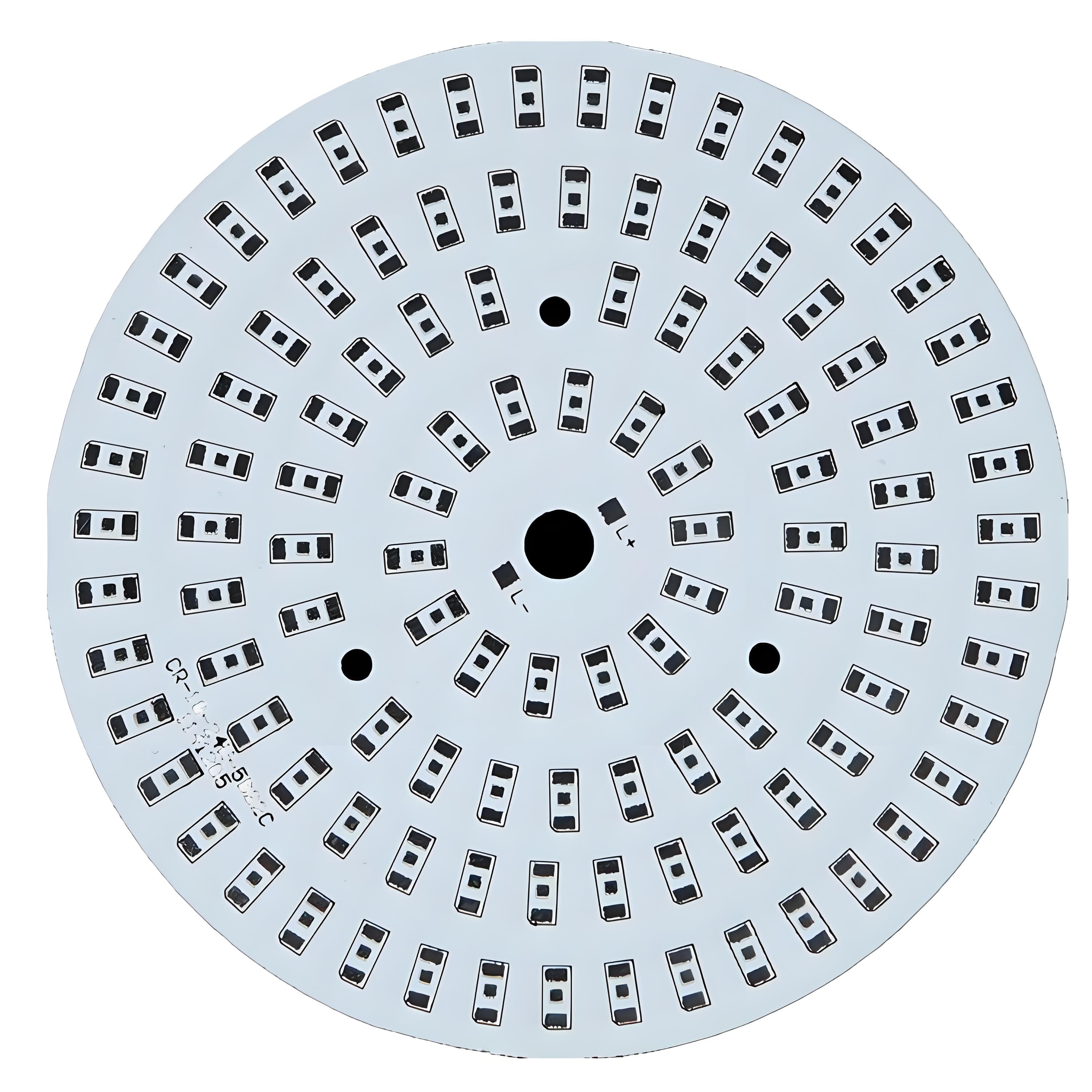

LED lighting aluminum substrate is a circuit board with aluminum as the base, on which the LED chip is directly soldered, which is both conductive and acts as a heat sink. Aluminum’s high thermal conductivity instantly dissipates heat, preventing LED overheating and light decay, allowing high-power LEDs to maintain a long lifespan and continuous high brightness.

Are you curious about BEST Technology’s aluminum substrates for LED lighting?

- Does the thermal conductivity meet the cooling requirements?

- Do the dimensions match the fixture’s installation requirements?

- Can the material and craftsmanship withstand high temperatures?

- Is the performance and cost-performance ratio reasonable?

- Does BEST Technology offer customization and after-sales service?

BEST Technology’s aluminum substrates for LED lighting can answer these questions.

- Compatible. The aluminum base and ceramic-filled insulation layer design offers far superior thermal conductivity compared to traditional substrates, rapidly dissipating heat from the LED and ensuring stable operation.

- Compatible. Standard sizes and full customization (non-standard shapes and thicknesses) are available. Small batches and samples can be delivered quickly, and the product is compatible with diverse lamp structures.

- Performance. The insulation layer has undergone high and low temperature cycling tests to ensure no delamination, and its long-term operating temperature reaches 150Ā°C. The thermal expansion coefficient is optimized for the LED chip, providing strong resistance to thermal stress.

- Reasonable. The zoned heat dissipation design saves costs, improves thermal conductivity by hundreds of times, and is priced lower than international brands, balancing longevity and affordability.

- Support. Full customization is provided (design, materials, and craftsmanship). After-sales service includes a 48-hour response time, free repairs during the warranty period, and 24-hour delivery for expedited orders.

What is the substrate of LED lights?

In simple terms, the substrate is the base material that supports the LED chip. It provides structure, stability, and heat management. Think of it as the “backbone” of the LED light.

LED chips generate light when electricity passes through them. But they also produce heat at the same time. If the heat isnāt managed, it can shorten the life of the LED and lower its performance. Thatās where the substrate plays a critical role.

Among many options, aluminum substrates stand out as the preferred choice for LED lighting. They are designed not only to hold the LED components but also to transfer heat away quickly, ensuring the light stays cool and lasts longer.

Why use aluminum substrates for LED lighting?

LEDs are sensitive to high temperatures. Excessive heat can cause them to fade, fail early, or lose brightness. Aluminum substrates prevent this problem.

Aluminum is an excellent conductor of heat. When used as a substrate, it helps channel heat away from the LED chip to the surroundings. This ensures consistent performance and protects the LEDs from damage.

Besides thermal benefits, aluminum substrates also offer strong mechanical support. They are lightweight yet durable, making them perfect for modern LED designs. Whether used in a slim LED panel or a high-power street light, aluminum substrates ensure efficiency and reliability.

What materials are LED lights made of?

LED lights are more than just chips and covers. Several layers and materials come together to create the final product:

- LED chip: The tiny semiconductor that produces light.

- Substrate: The base material, often aluminum, that supports and cools the chip.

- Circuit layer: Usually made of copper, it carries the electrical signals.

- Dielectric layer: Provides insulation while allowing heat to pass through.

- Lens or cover: Shapes the light and protects the chip.

Among these, the LED lighting aluminum substrate is one of the most critical parts. It combines electrical insulation with thermal conduction, two qualities rarely found together.

Can LED lights go on metal?

Yes, LEDs can be mounted on metal, and aluminum is the most common choice. In fact, many LED assemblies are designed specifically for metal bases.

When LEDs are mounted on aluminum, they gain improved heat dissipation. This is essential for applications like automotive lighting, industrial lamps, and high-brightness panels where heat is a big concern.

Unlike bulky cooling systems, aluminum substrates provide natural thermal management.

How does LED aluminum improve heat dissipation?

Heat dissipation is the most important function of aluminum substrates. Without it, LEDs would overheat and fail quickly.

Aluminum has high thermal conductivity. It pulls heat away from the LED chip and spreads it across the substrate. From there, the heat is released into the air.

Compared to traditional substrates, aluminum is far superior in thermal management. For example, FR4 (a common PCB material) cannot handle high heat as well.

In short, LED aluminum substrates work as natural heat spreaders. They extend the lifespan of LEDs, maintain brightness, and allow lights to perform at their best even in challenging conditions.

Why are aluminum substrates better than FR4 for LEDs?

FR4 is a widely used PCB material made of glass fiber and epoxy resin. While it works for many electronic devices, it struggles when used in LED lighting.

Hereās why aluminum substrates are superior:

- Better heat conduction: Aluminum conducts heat up to 10 times faster than FR4.

- Higher durability: Aluminum substrates can handle higher temperatures without damage.

- Stronger support: They provide a stable base for high-power LED chips.

- Longer lifespan: LEDs last longer when mounted on aluminum compared to FR4.

Because of these advantages, aluminum substrates are the first choice for most LED lighting products. FR4 may still be used in low-power LED designs, but for serious performance, aluminum is the winner.

What makes LED aluminum durable and reliable?

Reliability is everything in lighting. Aluminum is naturally strong and resistant to cracking. It also handles environmental stress well, such as vibration, impact, and moisture. This makes it ideal for outdoor and industrial LED applications.

The dielectric layer used in aluminum substrates also ensures electrical insulation. It prevents short circuits while allowing heat transfer.

In addition, LED lighting aluminum substrates resist thermal aging. They maintain their properties over time, even under constant heat. This means consistent performance, longer lifespans, and fewer replacements.

Where are LED lighting aluminum substrates applied?

The use of aluminum substrates in LED lighting is nearly endless. From household lights to industrial equipment, they are everywhere. Some common applications include:

- Street lights: High-power LEDs need aluminum substrates to stay cool.

- Automotive lighting: Headlights, brake lights, and interior lights benefit from aluminumās durability.

- Consumer electronics: Backlighting in TVs, displays, and smartphones.

- Industrial lamps: Used in warehouses and factories where reliability is key.

- Medical devices: Precision lights where stable output is essential.

- Architectural lighting: Decorative LEDs that need consistent brightness.

Wherever LEDs are used, aluminum substrates play a key role in making them efficient and reliable.

Why are LED lighting aluminum extrusions important?

In addition to substrates, LED lighting aluminum extrusions are often used for housing and thermal management. These extrusions are aluminum profiles designed to protect LEDs and spread heat.

When combined with aluminum substrates, extrusions create a complete thermal solution. They not only manage heat but also improve the appearance and durability of LED products.

Conclusion:

The LED lighting aluminum substrate is the foundation of reliable LED technology. It supports the chip, improves thermal management, and ensures durability. Compared to FR4, aluminum is far superior in heat conduction and reliability. Thatās why itās the top choice for everything from street lights to smartphones.

In short, aluminum substrates make LEDs brighter, cooler, and longer-lasting. If you are looking for high-quality LED lighting aluminum substrates, reach out to us at sales@bestpcbs.com

Tags: aluminum substrates, LED lighting aluminum substrate, led substrates