Ask any engineer, audio producer, or network specialist about their biggest frustrations, and signal to noise ratio (SNR) will likely top the list. From fuzzy audio recordings to dropped Wi-Fi connections and inaccurate sensor data, poor SNR derails projects, wastes time, and hurts end-user experiences. After diving into Reddit threads, EEVblog Forum discussions, Stack Exchange debates, and industry insights from All About Circuits and EDN Network, weâve compiled a no-fluff guide to understanding, calculating, and optimizing SNRâtailored to what real users actually need.

What Is Signal to Noise Ratio (SNR)? Core Definition & Real-World Impact

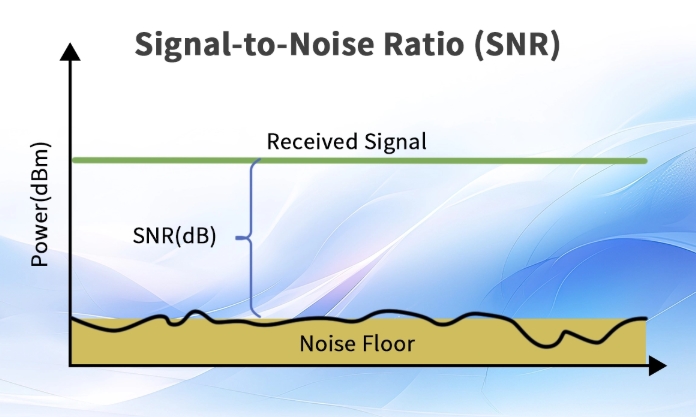

At its simplest, signal to noise ratio (SNR) is a measure of how strong a useful signal is compared to the unwanted background noise that distorts it. Expressed in decibels (dB), itâs a logarithmic scale that tells you how âcleanâ your signal isâhigher dB values mean clearer, more reliable data, while lower values mean noise is winning the battle.

SNR isnât just a technical checkbox; itâs a make-or-break factor across industriesâespecially for printed circuit board (PCB) designs, where noise mitigation directly impacts performance. A low SNR in medical sensors (reliant on precision PCBs) can lead to misdiagnoses, while poor SNR in high-frequency PCBs undermines wireless communication stability. For audio equipment or industrial controls, bad SNR from subpar PCB grounding or shielding turns functional designs into faulty products. Every engineer knows: mastering signal to noise ratio (SNR) starts with intentional PCB designâsomething Best Technology has refined over 19 years of crafting custom PCB solutions.

How to Calculate SNR: Power, Voltage & Digital (PSNR) Formulas

Power-Based SNR Formula (Basic)

The foundational formula for signal to noise ratio (SNR) compares signal power (Psignal) to noise power (Pnoise). The logarithmic scale simplifies large value ranges, making it easier to interpretâcritical for engineers designing PCBs where signal and noise values can vary drastically:

SNR (dB) = 10 Ă logââ (Psignal / Pnoise)

A positive dB value means your signal is stronger than noise; negative values indicate noise is overwhelming your dataâsomething EEVblog users warn leads to irreversible signal loss in analog circuits and high-frequency PCBs. For example, a +30 dB SNR is ideal for high-speed PCBs, while values below +10 dB often result in data corruption.

Voltage-Based SNR for Analog Systems & PCBs

For analog devices like microphones or sensor PCBs, SNR is often calculated using voltage instead of power. Since power is proportional to voltage squared, the formula adjusts to:

SNR (dB) = 20 Ă logââ (Vsignal / Vnoise)

This is particularly relevant for medical device PCBs (requiring ISO 13485 certification), where precise voltage measurements directly impact SNR and patient safety. All About Circuits community guidelines note that a 40 dB SNR (e.g., 2V signal vs. 0.02V noise) is the minimum for reliable analog PCB performanceâsomething Best Technology prioritizes in custom medical PCBs.

PSNR for Digital Media & PCB-Embedded Systems

Peak Signal-to-Noise Ratio (PSNR), a variant of SNR, is vital for digital content and PCB-embedded systems like smart devices. It uses the maximum pixel value (255 for 8-bit images) and Mean Square Error (MSE) to measure quality after compression:

PSNR (dB) = 10 Ă logââ (MAXIÂČ / MSE)

Googleâs SpecAugment technology relies on PSNR to optimize audio spectrograms in PCB-powered devices like smart assistants. For PCBs used in video processing, Best Technologyâs high-frequency PCBs support PSNR values â„30 dBâensuring sharp, noise-free digital outputs.

Key Noise Sources That Ruin SNR (And How to Identify Them)

Stack Exchange and EEVblog threads are flooded with questions about âunexplained SNR dropsââmost trace back to three common sources, with PCB design flaws being a top culprit. Hereâs how to spot and address each:

Thermal Noise (Johnson-Nyquist Noise)

Unavoidable and temperature-dependent, thermal noise stems from electron motion in conductors. It increases with resistance, bandwidth, and heatâ a major challenge for industrial PCBs operating in harsh environments. Use the Johnson-Nyquist equation to estimate it: Vn,rms = â(4kTRB). Best Technology mitigates this by integrating metal-based PCBs (MCPCBs) for superior thermal dissipation, preserving SNR even at high temperatures.

1/f Noise (Flicker Noise)

Redditâs r/AskElectronics community calls 1/f noise the âsilent killerâ of low-frequency PCBs (e.g., pressure sensor boards). It decreases as frequency increases, causing subtle drift in readingsâespecially problematic for precision medical PCBs. Look for noise that worsens at frequencies below 1kHz; Best Technologyâs ceramic PCBs minimize this with low-defect materials and optimized trace layouts.

Electromagnetic Interference (EMI) in PCBs

External EMI (power lines, Wi-Fi) is preventable, but internal EMI from poorly designed PCBs is equally destructiveâEDN Network experts note 70% of high-speed PCB SNR failures stem from this. Poor shielding, inadequate grounding, or haphazard component placement amplifies EMI. Best Technology addresses this through strict PCB design rules: separating analog/digital grounds, using shielded layers, and complying with REACH/RoHS standards to ensure EMI-free performance.

Debunking 3 Common SNR Myths (From Engineering Forums)

Misinformation about signal to noise ratio (SNR) leads to costly PCB design flaws. Letâs bust three myths circulating on EEVblog and Stack Exchange, backed by expert consensus:

Myth 1: Smaller Resistors Always Improve SNR

EEVblog users repeatedly debunk this. While thermal noise increases with resistance, reducing resistor size can lower signal voltage (per Ohmâs law) faster than noise decreases. For current-measurement PCBs, doubling resistance boosts SNR by ~3 dBâbalance is key. Best Technologyâs PCB design service optimizes resistor selection based on circuit needs, avoiding one-size-fits-all mistakes.

Myth 2: Positive SNR Means âGood Enoughâ Performance

A +10 dB SNR works for basic voice calls but fails for aerospace or medical PCBs (requiring AS9100D/ISO 13485 compliance). Stack Exchange engineers note Wi-Fi 6 PCBs need â„25 dB SNR for 1Gbps speeds, while fiber optic PCBs require â„40 dB. Best Technology tailors SNR targets to industry standards, ensuring compliance and reliability.

Myth 3: Software Can Fix Any SNR Issue

Redditâs r/engineering community agrees: Software (digital filtering) mitigates noise but canât recover lost signal data. If your PCBâs SNR is -5 dB, no algorithm will save itâfocus on hardware fixes first. Best Technologyâs one-stop solution combines low-noise PCB design, component sourcing, and assembly to build SNR resilience from the ground up.

Hardware Strategies to Improve SNR (Low-Cost & Professional)

All About Circuits users prioritize actionable hardware tipsâhereâs how to boost SNR for PCBs, from low-cost tweaks to professional-grade solutions backed by Best Technologyâs 19 years of experience:

Low-Cost Fixes (No New Components Needed)

- Optimize Grounding: Separate analog/digital grounds to prevent noise bleedâEEVblog experts call this the âmost underrated SNR fix.â Best Technologyâs PCB design service enforces this rule for all custom boards.

- Reduce Bandwidth: Narrow your signalâs frequency range via filters to cut thermal noiseâideal for industrial control PCBs.

- Shield Critical Traces: Use copper shielding on high-sensitivity traces (e.g., sensor PCBs) to block EMI, a low-cost tweak with high impact.

Professional-Grade PCB-Centric Solutions

- Low-Noise PCB Design: Best Technology integrates dedicated ground planes, optimized layer stacking (signal layers adjacent to ground), and strategic component placementâproven to boost SNR by 15-20 dB. Our team uses advanced EDA tools supporting 150k+ pin designs for precision.

- Specialized PCB Materials: Metal-based (MCPCBs) and ceramic PCBs minimize thermal/1/f noise, ideal for high-temperature or low-frequency applications. We offer all material types, from standard FR4 to high-frequency PCBs.

- Precision Assembly: Our PCB assembly service pairs low-noise op-amps (â€1nV/âHz) with damping resistors (22â33Ω) to slow signal rise/fall times, reducing high-frequency EMI. We source components globally and ensure UL compliance.

Software Hacks to Boost SNR Without Changing Hardware

Reddit users frequently ask how to improve SNR when PCB upgrades arenât an option. These software tricks, tested by engineers, complement hardware design and deliver tangible results:

Data Averaging (For Sensor PCBs)

Average multiple readings to reduce random noiseânoise decreases with âN (number of samples). For example, 100 samples cut noise by 10x (20 dB). Pythonâs NumPy library simplifies this for PCB-embedded microcontrollers, a tip shared on Stack Exchange.

Digital Filtering & Spectrogram Optimization

Use FIR/IIR filters to remove out-of-band noise. For audio PCBs, Audacityâs âNoise Reductionâ tool (12-15 dB) cleans recordings without muffling sound. Googleâs SpecAugment takes this further by augmenting spectrograms in PCB-powered devices, improving speech recognition SNR without hardware changes.

Error-Correcting Codes (For Wireless PCBs)

Convolutional or LDPC codes boost SNR resilience in 5G and Wi-Fi PCBs. Stack Exchange telecom engineers note these codes compensate for 3-5 dB SNR losses, keeping connections stable. Best Technologyâs high-frequency PCBs support these codes for industrial IoT applications.

Industry-Specific SNR Standards: Whatâs âGoodâ SNR?

EDN Network and All About Circuits compile industry benchmarksâhereâs what constitutes acceptable signal to noise ratio (SNR) for PCBs across key fields, aligned with Best Technologyâs certification and capabilities:

- Wireless Communications: Bluetooth BLE PCBs need â„5 dB (min), â„15 dB (ideal); 5G PCBs require â„-1 dB (min), â„20 dB (ideal). Our high-frequency PCBs exceed these standards for stable connectivity.

- Medical Devices: Precision sensor PCBs (ISO 13485 certified) need â„80 dB. Best Technologyâs custom medical PCBs are engineered to meet this for diagnostic accuracy.

- Aerospace: AS9100D-certified PCBs require â„70 dB. We deliver rugged, noise-optimized boards for aerospace applications.

- Consumer Electronics: Audio PCBs â„60 dB; video processing PCBs â„30 dB PSNR. Our flexible and rigid-flex PCBs support these for seamless user experiences.

SNR Measurement Tools: Hardware & Software Best Practices

Accurate SNR measurement ensures PCB performanceâhere are tools and techniques trusted by EEVblog and Stack Exchange engineers, paired with how Best Technology validates boards:

Hardware Tools

- Spectrum Analyzers: Agilent N9340B for RF PCB SNR testingâwe use this to validate high-frequency PCBs.

- Oscilloscopes: Tektronix MDO3000 series for voltage-based SNR calculationsâstandard in our quality control.

- Noise Figure Meters: Keysight N8975A to quantify component-induced SNR lossâcritical for medical PCB certification.

Software Tools

- iwconfig (Linux): Test Wi-Fi PCB SNR in real timeâused for IoT PCB validation.

- Python Scripts: NumPy/Matplotlib to simulate SNR pre-productionâintegrated into our PCB design workflow.

- EDA Software: Automated SNR-focused design reviewsâensuring no flaws slip through.

SNR in Wireless Communications (Wi-Fi 6, 5G, Bluetooth) PCBs

Wireless PCBs face unique SNR challengesâdistance, interference, and multipath fading. Stack Exchange and EDN Network experts share these optimization tips, which Best Technology incorporates into custom designs:

- Wi-Fi 6 PCBs: Use 5GHz band, high-gain antennas, and optimized trace routing. Our PCBs reduce SNR loss by 6 dB per distance doubling.

- 5G PCBs: Beamforming compatibility and EMI shieldingâour high-frequency PCBs support this for dense environments.

- Bluetooth BLE PCBs: Compact footprint with minimal wire runsâour rigid-flex PCBs minimize EMI and preserve SNR within 10-meter ranges.

SNR for Audio & Video Production PCBs

Content creators on Redditâs r/audioengineering rely on SNR for professional outputsâhereâs how PCB design impacts audio/video SNR, with Best Technologyâs solutions:

Audio PCBs

Record with low-noise preamp PCBsâkeep input levels high (not clipping) to overpower noise. Best Technologyâs audio PCBs use dedicated ground planes and low-noise components to achieve â„90 dB SNR for Hi-Fi equipment.

Video PCBs

High ISO increases sensor noiseâvideo PCBs need low-capacitance traces to preserve SNR. Our ceramic PCBs minimize capacitance, supporting PSNR â„30 dB for 4K video without over-denoising.

FAQ: Common Signal to Noise Ratio (SNR) Questions

Q1: Why is SNR measured in decibels (dB) instead of a linear ratio?

Decibels compress large value ranges (1000x signal-to-noise = 30 dB, not 1000:1), making SNR easier to interpret for PCBs. It aligns with how human perception and electronic measurements workâcritical for cross-industry consistency.

Q2: Whatâs the difference between SNR and SINR for PCBs?

SNR measures signal vs. background noise; SINR (Signal-to-Interference-and-Noise Ratio) includes intentional interference (adjacent Wi-Fi channels). SINR is key for crowded wireless PCBs, while SNR matters for controlled environments (medical sensors).

Q3: How does temperature affect SNR in PCBs?

Thermal noise increases with temperatureâevery 10°C rise boosts noise by ~1.5x. Best Technologyâs MCPCBs and thermal management designs stabilize SNR in -40°C to 125°C industrial environments.

Q4: Can I improve SNR in existing PCBs without redesign?

Yesâadd shielding, rework grounding, or use software filtering. For best results, our component sourcing and rework service optimizes existing PCBs to boost SNR by 5-10 dB.

Q5: How do you validate SNR for certified PCBs (ISO 13485, AS9100D)?

We use calibrated noise figure meters and spectrum analyzers, paired with third-party testing, to ensure SNR meets certification standards. Every batch of medical/aerospace PCBs includes a SNR validation report.

Q6: What PCB material is best for maximizing SNR?

Ceramic PCBs minimize 1/f noise, MCPCBs reduce thermal noise, and high-frequency materials (PTFE) lower EMI. Best Technology recommends materials based on your SNR goals and application.

Partner With Best Technology for Superior SNR-Focused PCB Solutions

When it comes to signal to noise ratio (SNR), your PCB design is the foundation of reliable performanceâand Best Technology is your trusted partner to get it right. Founded in 2006, we bring 19+ years of expertise in one-stop PCB solutions, from low-noise design and prototyping to mass production (260,000 square feet monthly capacity) and box-build assembly. Our ISO 9001:2015, ISO 13485:2016, AS9100D, and IATF 16949 certifications ensure your PCBs meet strict SNR and industry standards, whether for medical devices, aerospace systems, or consumer electronics. We offer 24-hour expedited service for urgent projects, global component sourcing, and personalized support to tailor every PCB to your SNR needs. Stop wasting time troubleshooting noise-related failuresâlet our team of PCB and SNR experts design a solution that delivers clear signals, consistent performance, and compliance. Contact us today for a free consultation, and turn your SNR challenges into high-quality, market-ready products.

Tags: SNR