A custom LED board is a tailored printed circuit board designed specifically to support LED arrays, offering optimized performance for high-power applications. This article explains how custom LED boards enhance thermal management, reliability, and efficiency in high-power systems, from automotive lighting to commercial signage.

Are you struggling with heat-related issues in your high-power LED projects? Many users face common challenges when using standard boards for demanding applications.

- βHeat accumulationβ causing rapid LED degradation and reduced lifespan.

- βInefficient thermal dissipationβ in FR-4 boards leading to brightness loss.

- βThermal resistance problemsβ resulting in unstable performance under high loads.

- βLimited customizationβ for unique shapes or power requirements.

- βHigh failure ratesβ due to poor heat handling in generic PCBs.

To overcome these issues, custom LED PCB boards integrate advanced thermal management solutions.

- βMetal Core PCBs (MCPCB)ββ using aluminum or copper bases improve heat conduction.

- βHigh-thermal-conductivity materialsβ minimize thermal resistance.

- βVacuum lamination processesβ ensure robust layer bonding.

- βCustomized layoutsβ optimize heat pathways for even distribution.

- βHigh-temperature solderingβ enhances durability under prolonged use.

As a premium metal core PCB manufacturer, BEST Technology specializes in custom LED boards, leveraging expertise in metal-core substrates and thermal design to deliver reliable solutions for high-power systems. Pls feel free to contact us at sales@bestpcbs.com for projects requiring precision and performance.

What is Custom LED Board?

A custom LED board is a purpose-built circuit board that hosts LED components in a layout tailored to specific applications, such as automotive lighting or signage. Unlike off-the-shelf boards, these are engineered to address unique power, size, and thermal needs.

- βDefinition: It typically includes a substrate (e.g., FR-4 or metal-core), conductive traces, and LED placements optimized for efficiency.

- βApplications: Used in custom LED sign boards, custom truck LED light boards, and custom LED tail light boards, where standard boards fall short.

- βAdvantages: Customization allows for better heat handling, which is critical for high-power systems.

In summary, a custom LED board provides a foundation for LEDs to operate reliably under demanding conditions.

How to Build Custom LED Board?

Building a custom LED board involves design, material selection, and manufacturing steps focused on thermal performance.

- βStep 1: Design the circuitβ β Create a LED circuit board diagram using software, considering power distribution and heat spots.

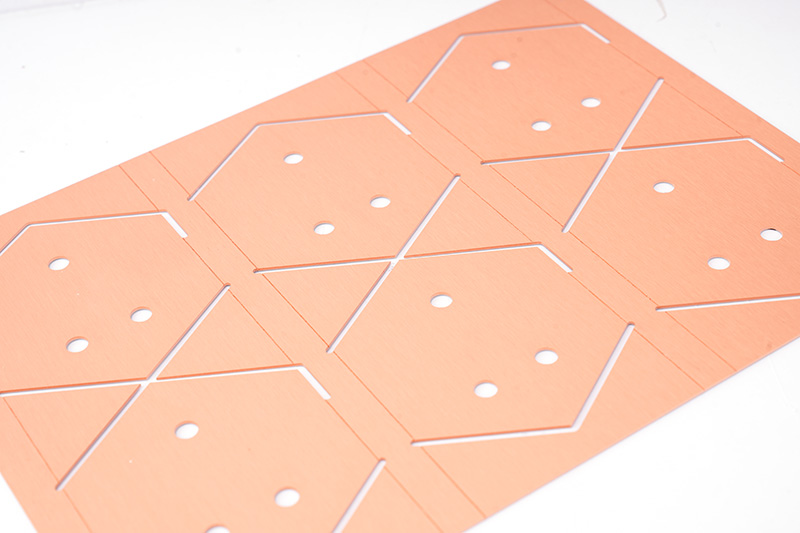

- βStep 2: Choose substratesβ β Opt for MCPCBs (e.g., aluminum-based) for high-power projects to enhance cooling.

- βStep 3: PCB fabricationβ β Processes like etching and plating form the traces; for SMD LED PCB designs, precision placement is key.

- βStep 4: Assemblyβ β Solder LEDs using high-temperature methods to withstand heat.

- βStep 5: Testingβ β Verify thermal performance and brightness stability.

This process ensures the board meets specific needs, such as a custom LED panel for car or outdoor custom LED sign board.

How to Remove LED Ring Board Custom Arena?

Removing a custom LED ring board, often used in arenas or decorative signs, requires care to avoid damage.

- βPower downβ β Disconnect electricity to ensure safety.

- βDetach mounting hardwareβ β Unscrew or unclip the board from its frame.

- βDisconnect wiringβ β Gently remove connectors from the LED circuit board.

- βUse tools cautiouslyβ β Avoid prying to prevent breaking the custom LED light board.

Proper removal allows for upgrades or repairs, maintaining the integrity of high-power systems.

What Can You Do with a Custom LED PCB Board?

Custom LED PCB boards enable versatile applications by offering tailored solutions.

- βAutomotive upgrades: Create custom LED board for car designs, like DRLs or tail lights, for better visibility.

- βSignage: Build customizable LED message boards for shops or trade show displays custom LED board.

- βIndustrial use: Develop LED array PCB for high-power lighting in factories.

These boards support innovation while ensuring efficiency, thanks to optimized thermal management.

Why Many Car Owners Choose Custom Made LED Tail Lights for Better Visibility?

Custom made LED tail lights enhance safety through superior design and performance.

- βBrightness: Custom LED boards use high-output LEDs for clearer visibility in all conditions.

- βDurability: MCPCBs in custom LED tail light board designs reduce heat-related failures.

- βAesthetics: Tailored shapes, like custom LED chevron boards, improve vehicle appearance.

This makes them a popular choice for automotive enthusiasts seeking reliability.

What Makes a Custom LED Sign Board Stand Out for Shops and Events?

Custom LED sign boards attract attention with their adaptability and efficiency.

- βVisibility: High-power LEDs on custom LED sign boards remain bright over time.

- βCustomization: Options like personalized LED board designs fit brand themes.

- βThermal management: MCPCBs prevent dimming, crucial for outdoor custom LED board use.

Thus, they stand out by combining aesthetics with longevity.

Why a Custom Truck LED Light Board Is Popular for Automotive Upgrades?

Custom truck LED light boards are favored for their robustness and functionality.

- βPower handling: They support high-wattage LEDs without overheating.

- βCustom fits: Designs like custom truck LED light board football themes add personalization.

- βReliability: Metal-core PCBs ensure performance in rugged conditions.

This popularity stems from enhanced safety and customization options.

Why High-Power Projects Prefer Custom LED Circuit Boards with Better Heat Performance?

High-power LED projects require superior thermal management to maintain performance.

βHeat challenges: High-power LED modules generate significant heat, causing standard FR-4 boards to accumulate temperature, leading to light decay.

βMCPCB advantage: Custom LED circuit boards often use Metal Core PCBs (aluminum or copper) to improve heat paths and reduce thermal resistance.

Custom LED circuit boards’ Suppliers like EBest Circuit (Best Technology) employ high-thermal-conductivity materials, vacuum lamination, and high-temperature soldering to ensure LEDs stay bright and stable. This focus on heat performance makes custom boards ideal for demanding applications.

Why Choose EBest Circuit (Best Technology) for Custom PCB LED Board Manufacturing?

When you choose a partner for custom PCB LED board manufacturing, you need more than a standard PCB supplierβyou need a factory that understands heat, brightness stability, and long-term performance. EBest Circuit (Best Technology) specializes in delivering LED-focused MCPCB solutions that improve thermal balance, power efficiency, and reliability across a wide range of lighting applications.

1. Specialists in LED Thermal Management Materials

Heat control is the key factor for LED brightness and lifespan. EBest Circuit (Best Technology) focuses on the materials that deliver optimal thermal paths for LED boards.

Metal Core PCBs (Aluminum & Copper MCPCB)

- Ideal for high-power LEDs, automotive tail lights, custom LED arrays, and signage backlighting.

- Thermal conductivity options: 1.0β3.0 W/mΒ·K standard, higher values available on request.

- Supports single-layer, 2-layer, and hybrid stack-ups commonly used in LED modules.

High-Reflection White Solder Mask

- Boosts LED lumen output by improving light reflection.

High-TG FR4 for Cost-Sensitive LED Strips

- For low heat LED strips or decorative lighting where cost efficiency matters.

2. Precision Manufacturing for Consistent Light Output

Custom LED boards require tight control over copper distribution, impedance, and heat spreading. Our engineering focuses on LED-specific design rules.

Fine-Pitch LED Placement

- Achieves 2.5/2.5 mil line/space for dense LED arrays and LED display modules.

Controlled Copper Thickness

- 1β3 oz outer copper for LED strips, LED bars, and high-current segments.

Uniform Solder Mask & Surface Finish

- ENIG, Immersion Silver, and OSP optimized for LED solderability and brightness consistency.

Color Options for Aesthetic Needs

- White (high reflectivity) for lighting

- Black for automotive DRL/tail lights and signage

3. Quality You Can Trust for Lighting & Automotive Applications

LED boards operate under continuous heat, vibration, and sometimes outdoor conditions. EBest Circuit (Best Technology) delivers stable performance through:

- ISO 9001 β General quality assurance

- IATF 16949 β Automotive-grade LED PCBs (tail lights, DRL, headlights)

- UL Certification β Safety compliance for lighting modules

LED-focused inspections include:

- AOI for LED pad accuracy

- X-Ray for metal core structure

- Thermal testing for heat propagation

4. From Samples to Mass Production with Full Turnkey Solutions

We support LED customers who need fast development and reliable repeat production.

- Prototype MCPCB in 48β72 hours

- Stable mass production for LED strips, LED modules, sign boards, and automotive LED assemblies

- Assistance with LED pad design, thermal vias, and heat simulation

- Component sourcing for LEDs, drivers, connectors

5. Reliable Delivery for Lighting, Automotive, and Display Projects

LED projects often run on tight schedulesβespecially automotive upgrades, signboard installations, and custom lighting systems.

We maintain:

- 97% on-time delivery rate

- Real-time WIP tracking

- Dedicated engineering support for every order

Whether youβre building a custom LED tail light board, backlit display, LED strip, or large-area LED array, EBest Circuit (Best Technology) provides a stable and professional manufacturing process from start to finish.

Custom LED boards are essential for maximizing the efficiency and lifespan of high-power systems through dedicated thermal design. This article has highlighted their role in various sectors, from automotive to commercial lighting. BEST Technology offers expertise in metal-core PCBs, HDI, and thick-copper boards, ideal for high-power LED, automotive, backlight, and advertising projects. For inquiries, pls feel free to reach us at sales@bestpcbs.com.

Tags: Custom LED Board, Custom LED Circuit Boards, Custom PCB LED Board