Why choose Colorado PCB assembly? This blog analyzes reasons for choosing Colorado, types and process workflow and recommended PCB assembly manufacturers.

Are you troubled with these questions?

- Is fragmented component procurement leading to uncontrolled costs?

- How can traditional factories cope with rapid iteration and sample verification cycles?

- Can small- to medium-batch orders enjoy professional-grade process assurance?

As a Global PCB assembly manufacturer, EBest Circuit (Best Technology) can provide you service and solutions:

- Supply Chain Collaboration Optimization: Integrating resources from hundreds of certified global suppliers, we provide centralized component procurement and consignment warehousing services, effectively reducing overall material costs by 25%.

- Agile Manufacturing System: Dedicated rapid-response production lines enable the entire sample production process, from surface mount technology (SMT) to testing, to be completed within 96 hours, supporting multiple engineering optimizations during the design phase.

- Layered Quality Control: For different fields such as consumer electronics and industrial equipment, we have built a multi-level inspection network from SPI to AOI, maintaining a stable first-pass yield of over 99.1% for key processes.

Welcome to contact us if you have any request for PCB assembly: sales@bestpcbs.com.

Why Choose Colorado PCB Assembly?

Advantages of Colorado PCB Assembly:

- Rapid Delivery Capability: Provides rapid prototyping and small-batch assembly services, shortening product development cycles and helping designers validate designs and bring them to market faster.

- Flexible Production Models: Supports various order sizes from prototypes to low-to-medium batches, meeting the needs of designers at different stages.

- One-Stop Component Procurement Service: Offers turnkey solutions, with a professional team responsible for component procurement, verification, and matching, reducing the burden of supply chain management.

- Strict Quality Standards: Follows industry standards such as IPC-A-610 and IPC-J-STD-001 to ensure reliable soldering and assembly quality.

- International Service Experience: Products have been exported to South Asia, North America, Europe, and other regions, possessing the language communication and logistics support capabilities to serve global customers.

- Competitive Pricing: Providing designers with cost-effective solutions by optimizing processes and controlling costs through supply chain management while ensuring quality.

- Technical Support and Collaboration: Having an experienced team of engineers who can provide professional support such as design optimization and manufacturability analysis to help improve the first-time success rate of products.

Types of Colorado PCB Assembly Services

- Surface Mount Technology (SMT): Components are directly mounted on the PCB surface. Suitable for high-density, miniaturized designs, ideal for mass production in consumer electronics, communication equipment, etc.

- Through-Hole Technology (THT): Component leads are inserted into drilled holes in the PCB and secured by soldering. Offers high mechanical strength and is commonly used in industrial, medical, and defense products with high reliability requirements.

- Hybrid Technology Assembly: Combines SMT and THT on the same PCB, balancing high density and strong mechanical connections. Suitable for complex or high-reliability electronic devices.

- Fast Turnaround Assembly: Provides short-cycle PCB assembly services for clients with urgent prototype needs, accelerating product development and verification.

- Turnkey Service: The service provider handles everything from component procurement and PCB manufacturing to assembly and testing, reducing the client’s supply chain management burden.

- Small Batch Assembly: Suitable for startups or customized projects, supporting small to medium batch orders and flexibly responding to market demands.

- Integrated PCB Manufacturing and Assembly: Providing end-to-end services from PCB fabrication to component assembly, ensuring consistency from design to finished product.

Top Colorado PCB Assembly Manufacturers in 2025

Advanced Circuits (AdvancedPCB)

- Business: Offers end-to-end PCB manufacturing and assembly from prototype to volume production, supporting single-layer, double-layer, multi-layer (up to 10-layer standard), HDI, and high-frequency PCBs.

- Strengths: US-based manufacturing with advanced facilities in Aurora, Colorado. Provides same-day/standard lead times, free design verification software, and no minimum order quantity. Certified under ISO 9001 and IPC-A-610 standards, with rapid customer service response.

Colorado PCB Assembly

- Business: Specializes in rapid-turnaround, small-batch, and turnkey assembly services, covering PCB manufacturing, component procurement, and assembly.

- Strengths: Located in Centennial, certified under RoHS and ISO standards. Emphasizes flexibility in quick prototyping and low-volume production, ideal for R&D and small-to-medium-scale projects.

Circuits West

- Business: Standard and custom PCB design, manufacturing, and assembly, including multi-layer (up to 18 layers) and double-sided boards.

- Strengths: Over 30 years of experience, ITAR-registered, and ISO 9001:2015 certified. Serves high-reliability sectors like medical and industrial, providing one-stop solutions from design to assembly.

PCB Prime

- Business: Printed circuit board manufacturing and supply, supporting prototype and medium-batch orders.

- Strengths: Based in Aurora, certified under ISO 9001:2015, UL, and RoHS. Focuses on cost-effectiveness and fast delivery, suitable for startups and mid-sized clients.

Rocky Mountain Circuits

- Business: PCB manufacturing and assembly, focusing on industrial, defense, and aerospace applications.

- Strengths: Operates a facility in Longmont, ITAR-registered, and ISO 9001 certified. Since 1972, delivers high-quality PCBs, specializing in complex multi-layer boards and environmentally resistant designs.

PNC Inc.

- Business: Full-cycle PCB assembly from concept to finished product, including design, manufacturing, component sourcing, and testing.

- Strengths: Owns in-house production lines, supports up to 40-layer board manufacturing. Offers online instant quoting, ideal for OEM/ODM projects requiring full process control.

NOVA Engineering

- Business: Full-service PCB assembly, including turnkey and consigned modes, from prototype to volume production.

- Strengths: Established in 1979, located in Denver. Equipped with three fully automated production lines and a dedicated prototyping line. Skilled in customized assembly across multiple industries, adhering to IPC standards.

Printed Circuit Board Assembly Processes

1. Material Preparation and Documentation Standards

- Core Documentation: Provide complete PCBA documentation including BOM (Bill of Materials), Gerber files, PnP (Pick-and-Place) files, test procedures, and assembly drawings. Documents must specify silkscreen markings, component polarity, test points, version control, and adhere to international standards (e.g., Extended Gerber RS-274X).

- Environmental Compliance: Substrates, components, and soldering materials must meet RoHS 3.0 (restricting 10 hazardous substances including lead, mercury, cadmium) and REACH regulations. Avoid chemicals containing Substances of Very High Concern (SVHC).

- Supply Chain Management: Source components from certified suppliers to ensure quality and traceability. Avoid counterfeit parts. Plan production schedules and budgets considering lead times, especially for high-demand scenarios.

2. SMT (Surface Mount Technology) Process

- Solder Paste Application: Apply solder paste evenly to PCB pads via screen printing, controlling thickness and precision to prevent bridging or cold solder.

- Component Placement and Reflow Soldering: Use high-speed pick-and-place machines to accurately position components (e.g., resistors, capacitors, ICs). Pass PCBs through reflow ovens to melt solder paste, forming reliable joints. Optimize thermal profiles (e.g., ramp rate, peak temperature) to balance solder quality and component safety.

- AOI Inspection: Automated Optical Inspection (AOI) scans solder joints to detect defects (e.g., insufficient solder, shorts, component misalignment).

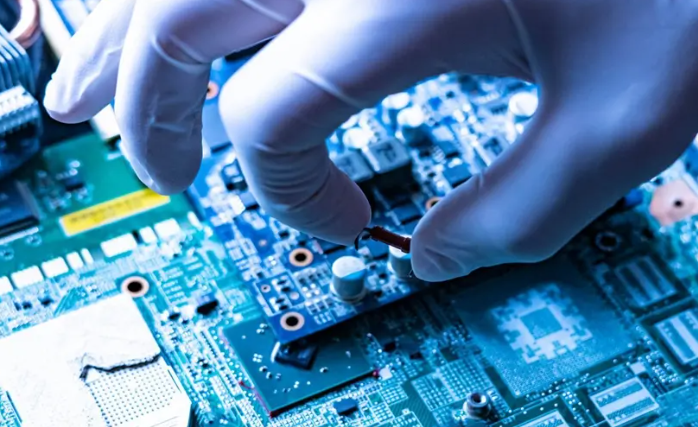

3. DIP (Dual In-line Package) Process

- Through-Hole Component Insertion and Wave Soldering: Insert through-hole components (e.g., electrolytic capacitors, connectors) manually or via automated machines. Wave soldering fills holes with molten solder, ensuring mechanical and electrical connections. Maintain component spacing (e.g., â¥10mil for discrete parts, 30mil preferred) to avoid soldering conflicts.

- Manual Soldering: For specialized components (e.g., large modules, sensitive devices) or low-volume production, manual soldering ensures flexibility. Control solder fillet shape and wetting.

4. Testing and Quality Control

- In-Circuit Testing (ICT): Use probe-based systems to test for opens, shorts, and component value deviations, ensuring electrical functionality.

- Functional Circuit Testing (FCT): Simulate real-world operating conditions to validate system-level performance (e.g., signal integrity, power management). Develop custom test fixtures and software.

- AOI/X-ray Inspection: AOI detects surface defects; X-ray inspection visualizes internal solder joints (e.g., BGA packages) to identify voids, cracks, or other hidden defects.

- Environmental and Safety Testing: Include solderability tests, contamination analysis (e.g., flux residue), and EMC compliance (e.g., CE/FCC standards).

5. Final Assembly and Packaging

- Hardware Integration: Install heat sinks, enclosures, connectors, and other components per customer specifications. Ensure mechanical stability and precision.

- Cleaning and Packaging: Use ultrasonic cleaning to remove solder residues and contaminants. Package products with anti-static, moisture-resistant, and shock-resistant materials. Include clear labeling and tracking information compliant with international logistics standards.

6. Special Requirements for International Clients

- Certification Compliance: Obtain certifications such as ISO 9001 (Quality Management), ISO 14001 (Environmental Management), UL (Safety), and IPC (Process Standards) to meet target market regulations.

- Recyclability Design: Adhere to WEEE Directive guidelines. Use modular designs, separable soldering materials, and eco-friendly substrates to enhance recyclability (e.g., â¥85% PCB recovery rate, â¥50% material reuse).

- Regulatory Adherence: Comply with EU directives (RoHS, REACH, Low Voltage, EMC) to ensure products are hazard-free, safe, and electromagnetically compatible, avoiding market access risks.

7. Design and Manufacturing Optimization

- DFM (Design for Manufacturability): Integrate manufacturing feasibility into PCB layout (e.g., component spacing, polarity markings, thermal management for large components, test point accessibility). Minimize rework costs through early-stage design optimization.

- Supply Chain Collaboration: Coordinate with component suppliers, PCB fabricators, and assembly houses to ensure seamless design-to-production transitions, enhancing efficiency and product quality.

Case Studies of Our Colorado PCB Assembly Projects

Project Background

- The client is a medical device manufacturer in Colorado requiring high-reliability, small-batch PCB assembly for the core module of a new monitoring device.

- Key requirements include rapid delivery, zero defect rate, and compliance with medical-grade EMC and safety certifications.

Solutions

- Customized Design Optimization: Re-planned power layout and shielding structure to address low-power consumption and signal integrity needs, using impedance-controlled routing to reduce signal attenuation.

- Rapid Prototyping and Iteration: Initiated Quick-Turn assembly process to complete first prototype and deliver testable PCBA within 5 working days after receiving design files.

- Full-Process Quality Control: Implemented AOI and X-Ray inspection points across SMT, reflow soldering, and testing stages to ensure soldering quality and component placement accuracy.

- Specialized Testing Validation: Added medical device-specific EMC testing and Environmental Stress Screening (ESS) to simulate long-term operational stability under temperature-humidity cycling and vibration conditions.

Results

- Delivery Timeliness: All batches delivered on schedule with 98.3% on-time delivery rate.

- Quality Metrics: First Pass Yield (FPY) improved to 99.8% with 0% field failure rate reported by the client.

- Cost Efficiency: Unit cost reduced by approximately 20% during small-batch phase through material procurement and process parameter optimization.

- Client Outcomes: Device successfully cleared FDA 510(k) clearance, shipped â¥5,000 units to market with zero PCBA-related recalls.

Why Colorado Clients Trust EBest Circuit (Best Technology) for PCB Assembly?

Reasons Why Colorado Clients Trust EBest Circuit (Best Technology) for PCB Assembly:

- 19 Years of PCBA Technology Accumulation, Industry Benchmark Strength Guaranteed: With 19 years of dedicated focus on PCB assembly, we have accumulated a massive process database and solutions to complex problems, ensuring efficient implementation of highly complex designs, avoiding trial production waste, and reducing overall development costs.

- 99.2% On-Time Delivery Rate, Precise Supply Chain Management: Leveraging a global collaborative supply chain network, we achieve precise management across the entire chain, from component procurement to finished product delivery, ensuring project progress and avoiding lost market opportunities.

- Free DFM Analysis, Pre-Design Risk Prevention: Our professional engineering team provides free Design for Manufacturability (DFM) analysis, identifying design defects in advance and providing optimization suggestions, reducing revisions, shortening development cycles, and lowering hidden costs.

- 24/7 Online Professional Engineer Response, Efficient and Seamless Technical Communication: Our multilingual professional engineering team seamlessly connects with designers through instant messaging tools, quickly resolving design questions and process adjustment needs, ensuring smooth project progress.

- Rigorous quality control system, transparent and reliable quality traceability: Adopting the IPC-A-610 standard certification and testing process, equipped with advanced equipment such as AOI and X-ray, and implementing 18 full inspection processes, each PCB is assigned a unique traceability code, and quality data is available for real-time tracking, ensuring product reliability.

- Outstanding cost competitiveness, transparent pricing: Reducing unit costs through large-scale procurement, lean production, and automated production lines, providing competitive pricing, promising no hidden fees, ensuring budget control, and improving project profit margins.

- Stringent environmental standards, meeting global certification requirements: Using lead-free processes and environmentally friendly materials, achieving international environmental certifications such as RoHS and REACH, meeting the stringent requirements of target markets for green manufacturing, and facilitating successful market access audits.

- Flexible production capabilities, rapid switching between multiple product types: Supporting all stages from prototype verification to mass production, equipped with rapidly adjustable automated production lines, achieving seamless transitions between small-batch orders and large-volume production, meeting the flexible project needs of designers.

- Localized supply chain support reduces logistics risks: Warehousing and service centers in North America and Europe provide localized logistics solutions, shortening delivery cycles, reducing international shipping losses, and improving supply chain stability and responsiveness.

- Successful case studies and proven reputation demonstrate strength: Having served over 500 well-known global electronics brands across communications, medical, and industrial control sectors, we possess a wealth of verifiable case studies and customer testimonials, proving ourselves as a trustworthy partner with tangible results.

Our PCB Assembly Manufacturing Capabilities

| Item | Capabilities |

| Placer Speed | 13,200,000 chips/day |

| Bare Board Size | 0.2 x 0.2 inches – 20 x 20 inches/ 22*47.5 inches |

| Minimum SMD Component | 01005 |

| Minimum BGA Pitch | 0.25mm |

| Maximum Components | 50*150mm |

| Assembly Type | SMT, THT, Mixed assembly |

| Component Package | Reels, Cut Tape, Tube, Tray, Loose Parts |

| Lead Time | 1 – 5 days |

How to Get A Quote for PCB Assembly Project?

All Documents Required for PCB Assembly:

- Gerber files: Contain geometric information for each layer of the PCB (copper traces, pads, solder mask, silkscreen, etc.), in .gbr format, and are the fundamental data for manufacturing.

- PCB design/engineering drawings: Include schematics, layout diagrams, interlayer wiring diagrams, 3D models, etc., clearly defining dimensions, hole positions, layer stack-up structures, and special process requirements (such as blind/buried vias, impedance control).

- Drilling files (.drl/.xin): Provide drilling coordinates, hole diameter, and dimension information to ensure drilling accuracy.

- Detailed BOM: Lists the model, specifications, quantity, supplier, brand, and procurement information of all components for cost estimation and procurement coordination.

- Special component specifications: Such as the size specifications of non-standard components, alternative material solutions, or environmental requirements (such as RoHS/ITAR compliance).

- Surface treatment standards: Such as HASL (Hot Air Leveling), ENIG (Electrochemical Nickel Gold), OSP (Optical Sterile Plating), immersion gold thickness, etc., directly affecting cost and quality.

- Testing Process: Includes AOI (Automated Optical Inspection), X-ray, ICT (In-Circuit Testing), flying probe testing, and functional testing to ensure product reliability.

- Assembly Process: Detailed requirements such as soldering temperature, surface mount accuracy, V-cut/stamp hole separation, and solder mask color (e.g., green solder mask/white lettering).

- Order Quantity and Annual Requirements: Clearly define the initial order quantity, batch size, and subsequent batch plans, affecting unit price and production schedule.

- Delivery Cycle: Initial order delivery date, expedited fees for urgent orders, and standard delivery time (usually 3 days to several weeks, depending on process complexity).

- Special Process Specifications: Such as through-hole pads, embedded components, laser direct forming (LDS), and high-frequency materials (e.g., Rogers 4350B).

- Quality Certifications and Standards: ISO, IPC, automotive/military/aerospace standards (e.g., TS16949, AS9001) to ensure compliance with industry specifications.

- Samples or Reference Boards: Used by the manufacturer to verify design feasibility, quality standards, and process compatibility.

- Contracts and Change Documents: Such as Engineering Change Notices (ECNs) and version control records, ensuring transparency in design iterations.

Welcome to contact us if you have any request for PCB assembly: sales@bestpcbs.com.

Tags: Colorado PCB Assembly, Colorado PCB Assembly Manufacturers