Why consider California for your flexible circuit assembly? This guide explores its manufacturing advantages, key applications, top suppliers, and how to get a quote for FPC assembly.

Are you worried about these questions?

- Do your FPC assemblies often require multiple reworks due to insufficient precision, delaying product launch timelines?

- When supply chain fluctuations occur, can you quickly secure stable, high-quality flexible circuit components?

- Does yield instability from complex designs make cost control more challenging than expected?

As a Flexible circuit assembly manufacturer in China, EBest Circuit (Best Technology) can provide you service and solutions:

- Precision Process Assurance: Leverage fully automated precision alignment tech to achieve micron-level assembly accuracy, slashing rework rates.

- Agile Supply Response: Tap into California-based localized production clusters for 7-10 day rapid delivery, easing stockout risks.

- Manufacturability Optimization: Intervene early in design phases with structural tweaks to boost yield, cutting costs by 15%+.

Welcome to contact us if you have any inquiry for flexible circuit board assembly: sales@bestpcbs.com.

Why Choose Flexible Circuit Assembly Manufacturer in California?

Advantages of flexible printed circuit assembly manufacturer in California:

- Supply chain efficiency and logistics convenience: The state’s mature electronic manufacturing ecosystem and robust supplier network enable manufacturers to source raw materials rapidly, shorten production cycles, and mitigate supply chain disruption risks.

- Technical expertise and innovation support: California hosts advanced producers like San Francisco Circuits, equipped to handle everything from single-layer to multi-layer flexible circuits. They offer rapid prototyping (as quick as 24 hours) and tailored solutions to meet evolving client needs.

- Quality standards and certification compliance: Adherence to global norms such as IPC 6012/6013, ISO 9001, and AS9100 ensures product reliability for high-stakes sectors like military and medical applications.

- Geographic proximity and market access: As a global tech hub (home to Silicon Valley), California facilitates close collaboration, accelerated iterations, and reduced shipping costs, ideal for tech projects requiring frequent teamwork.

- Flexible production and cost efficiency: Providers like Glenair eliminate minimum order constraints and leverage local production to minimize outsourcing dependencies, optimizing total costs while maintaining operational agility.

Applications of Flexible Circuit Assembly Manufacturing in California

- Aerospace & Defense: California firms like Summit Interconnect (Irvine) and Ascent Circuits (San Diego) craft rigid-flex HDI PCBs for satellite comms, avionics, and military radar. These circuits endure extreme temps and vibration while slashing equipment weight and boosting signal integrity.

- Automotive Electronics: Tesla and other EV makers deploy California-made flex circuits in battery management systems, self-driving sensors, and vehicle displays. TTM Technologies (Santa Clara) supplies solutions tailored to vehicle lightweighting and smartification trends.

- Medical & Wearables: Stanford teams developed flex-based stretch sensors for biocompatible wearables, think health patches and smart bandages. Ascent Circuits supplies precision flex assembly for medical imaging tools like endoscopes.

- Consumer Electronics: MFLEX (Anaheim) provides flex circuits for smartphones and tablets, enabling foldable hinge connections and compact internal routing. These prioritize high-freq signal transmission and repeated flex durability.

- Renewable Energy: Flex circuits power solar array interconnections, such as Lockheed Martin’s (Sunnyvale) lightweight PV modules using copper-silver metallization to boost energy capture. California PV inverter firms use flex circuits to optimize power module cooling and layout.

- Industrial & IoT: Flex circuits support industrial sensor grids and robotic dexterous manipulation in smart manufacturing lines. Lenthor Engineering (Milpitas) offers custom flex assembly for varied production needs.

Top Flexible Circuit Assembly Manufacturers in California

- Sonic Manufacturing Technologies: Based in Fremont, this firm delivers flexible circuit assembly services focused on rugged electronics like smartphones and wearables. Their team excels at building circuits on flexible plastic substrates, enabling reliable bending and folding operations.

- Multi-Fineline Electronix (MFLEX): Headquartered in Anaheim, MFLEX ranks among the world’s largest FPC and assembly solution providers. With global facilities in China and Malaysia, they meet high-quality demands in electronics through advanced tech and end-to-end solutions.

- Flex Interconnect Technologies (FIT): Located in Milpitas, FIT offers design, manufacturing, and assembly of flex circuits and rigid-flex boards. AS9100-certified and ITAR-registered, they scale from rapid prototyping to mass production, serving defense, aerospace, and medical sectors.

- San Francisco Circuits: With offices in San Mateo and San Diego, this firm has provided advanced PCB manufacturing and assembly since 2005. Their portfolio includes flex and rigid-flex PCBs, supporting rapid prototyping and turnkey solutions for medical and industrial systems.

- Sacramento PCB Assembly: Situated in El Dorado Hills, this company specializes in rigid-flex board assembly and custom design. Leveraging advanced inspection tech, they serve medical, renewable energy, and consumer electronics industries with a focus on client communication and tailored manufacturing.

- Lenthor Engineering: Based in Milpitas, Lenthor provides innovative flex circuit solutions including manufacturing and assembly. Decades of experience drive their focus on high-reliability applications like aerospace and automotive electronics.

- RUSH PCB Inc.: Headquartered in Milpitas since 1997, RUSH offers flex and rigid-flex PCB manufacturing. Their services span prototyping, assembly, and testing, catering to Silicon Valley’s high-tech needs, including HDI and microvia tech.

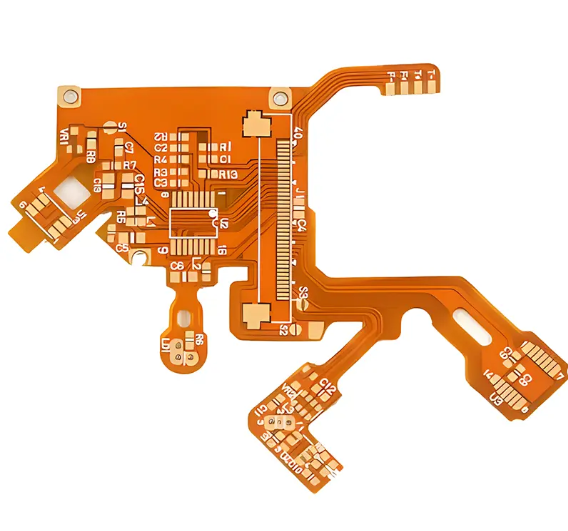

Flexible Circuit Board Assembly Manufacturing Process

1. Material Selection and Pretreatment

- Select polyimide (PI) or polyester (PET) flexible substrates paired with rolled copper foil or electrolytic copper foil as conductive layers. Clean surfaces chemically to remove oil, oxides, and impurities, followed by pre-baking (80–100°C for 4–8 hours, up to 125°C in special cases) to eliminate moisture and prevent delamination during reflow. Match copper foil thickness to design requirements (e.g., 1/3 oz for ultra-fine lines) and verify dimensional stability and bending resistance.

2. Circuit Pattern Formation

- Use laser direct imaging (LDI) or photolithography to transfer circuit patterns onto the substrate. Apply dry film, expose and develop to create precise graphics, then etch away excess copper with controlled etchant concentration and temperature to form high-precision conductive lines. Ensure line width/spacing meets specifications (e.g., 0.05mm for ultra-fine lines) to avoid shorts/opens, and use optical alignment for enhanced accuracy.

3. Lamination and Structural Reinforcement

- Bond multiple flexible layers with adhesive films (e.g., ACF, acrylic) under high temperature (160–200°C) and pressure (30–60 minutes). Apply segmented pressure control (low pressure to remove air bubbles, high pressure for curing) and manage heating rates (2–5°C/min) to prevent thermal stress warping. Match substrate CTE to ensure interlayer alignment deviation <50μm. Validate quality via ultrasonic scanning or X-ray inspection for bubbles/delamination.

4. Drilling and Via Processing

- Perform laser or mechanical drilling (diameter accuracy ±0.05mm), then deposit conductive layers on hole walls via electroless copper/electroplating for interlayer connections. Optimize drill selection (carbide/ceramic-based), speed (avoid burning/breaking), feed rate (prevent rough walls), and use air/suction for debris removal to avoid wall scratches. Reserve buffer zones in vias to mitigate stress concentration during bending.

5. Surface Plating and Protection

- Treat exposed copper lines with electroless nickel immersion gold (ENIG), organic solderability preservative (OSP), or immersion tin to enhance solderability and corrosion resistance. Control ENIG nickel thickness (3–5μm) and gold thickness (0.05–0.1μm), OSP film uniformity (0.2–0.5μm), and prevent tin whisker growth. Apply protective films (PI/PET) with smooth edges and validate adhesion via peel strength tests (>0.5N/mm).

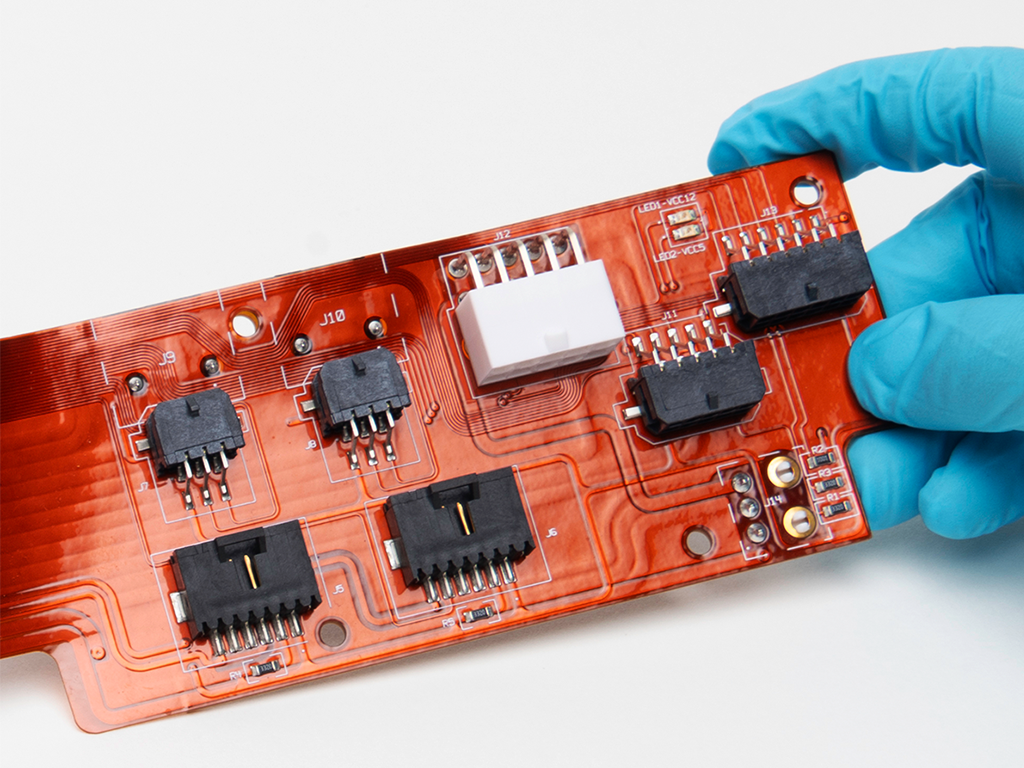

6. Component Mounting and Soldering

- Mount resistors, capacitors, ICs, etc., precisely using SMT machines (mid/high-speed) with optical MARK alignment (accuracy ±0.05mm). Use forced convection reflow ovens with temperature profiles (peak 220–240°C) to manage chain stability and airflow, preventing solder bridging/beading. For laser soldering, adjust power/time parameters to ensure robust joints without thermal damage.

7. Functional Testing and Quality Inspection

- Verify reliability via AOI (line defects), flying probe (continuity/insulation), bending tests (>10,000 cycles at ≤5mm radius), thermal shock (-40°C to 125°C cycles), and environmental tests (85°C/85% RH for humidity/salt spray). Measure dimensions (outline/hole accuracy), impedance (±10% tolerance), and inspect solder pads for oxidation/print clarity under microscopes. Final products undergo full FQC checks to meet IPC-6013 standards, ensuring no shorts/opens/delamination.

8. Packaging and Storage

- Package in anti-static bags/foam boxes to prevent compression, impact, or static interference. Store in dry (40–60% RH), ventilated, corrosion-free environments at 20±5°C to avoid moisture absorption and deformation. Secure pallets during transport to prevent component shifting.

How to Choose Flexible Circuit Board Assembly Manufacturer in California?

California Flexible circuit board assembly manufacturers selection guide:

1. Technical Capability and Equipment Sophistication

- Core Equipment and Processes: Prioritize manufacturers equipped with high-precision board-making devices (e.g., laser drilling machines, plating lines), automated production lines, and precision testing instruments. For example, Stanford University’s Bao Group utilizes maskless flexible microelectronics direct-write devices for minute-level design iteration and complex structure preparation, suitable for wearable epidermal electronics and flexible sensors.

- Cutting-edge Technology Cases: NASA employs Yixin Tech equipment to fabricate wearable CO₂ sensors; cases like fully printed seven-layer flexible zinc-magnesium batteries and ultrahigh-resolution microscale 3D chip interconnections validate technical maturity. Equipment requires real-time closed-loop pressure feedback, optical layer alignment, and AI-assisted functions to ensure adhesion and conductivity on complex substrates (silicone, paper, textiles).

2. Quality Management and Certification Systems

- International Certification Standards: Must pass CEC California Energy Efficiency Certification (Title 20/24), ISO9001, IATF16949, and comply with RoHS/CQC environmental requirements. CEC certification mandates product energy efficiency metrics, testing methods, and phased implementation plans; failure results in inability to sell in California. For instance, external power supplies must meet no-load power ≤0.5W and average efficiency ≥85%.

- Full-process Control Details: Strict standards from raw material procureure to final inspection, including incoming IQC, in-process IPQC, and final FQC. Cover film/layer deviations controlled below ±0.3mm, adhesive flow penetration <0.2mm, and minimum annulus width ≥0.05mm. Post-humidity test (40°C/90%/96h) ensures voltage resistance and bending performance compliance.

3. Client Cases and Reputation Evaluation

- Success Case Verification: CelLink’s collaboration with Lear enhances electric vehicle battery pack performance by reducing wiring harness weight by 70% and improving range. Yixin Tech equipment applies to NASA’s wearable CO₂ sensors, fully printed seven-layer flexible zinc-magnesium batteries, and biomedical/textile wearable electronics.

- Client Satisfaction Data: Third-party evaluations (e.g., international institutions) show premium manufacturers achieve <2% error rates in sample consistency (e.g., impedance, thickness) and >95% on-time delivery. Avoid low-price traps and substandard substrates like FR4 replacing high-frequency materials.

4. Geographic Location and Supply Chain Advantages

- Location Convenience: California, on the U.S. West Coast, offers direct flights from China, efficient logistics, and high Chinese community density for cross-cultural communication. Silicon Valley’s dense tech enterprises and active venture capital (top in U.S. for financing ease) foster technology collaboration and resource sharing. For example, CelLink in San Carlos leverages California’s innovation ecosystem for rapid design changes and mass production.

- Industry Cluster Effects: Flexible supply chains via diversified supplier networks and smart logistics reduce inventory costs and enhance response speed. Data indicates optimized supply chain management improves inventory turnover by 30% and cuts transportation costs by 20%.

5. Environmental Sustainability Practices

- Green Production Standards: Adopt non-chemical processes, low-metal-intensity designs, and recyclable materials to meet California’s strict environmental regulations. For example, Yixin Tech’s process reduces waste by 30% and lowers carbon emissions by 40% compared to traditional methods for CEC-certified products. California’s Proposition 65 requires warning labels for lead/cadmium-containing products; non-compliance risks lawsuits.

- Energy Efficiency Compliance: CEC mandates ≥85% operational efficiency for hair dryers by 2025 and ≤0.3W no-load power for adapters. Firms must update testing standards per regulatory changes, e.g., IEC 62301’s strict airflow (≤0.5m/s) and temperature control (23°C±5°C).

6. Cost-Benefit and Lead Time Guarantees

- Cost Transparency: Avoid quotes 20% below market rates; clarify included processes (laser drilling, plating), material specs (copper foil thickness), and after-sales terms. Raw material price volatility (copper foil, CCL) hedged via long-term agreements or futures markets.

- Delivery Time Assurance: Premium manufacturers achieve 7-14 day lead times via smart scheduling systems and <24-hour emergency response. For instance, CelLink shortens traditional 30-day lead times to 7 days with automated lines while maintaining >99% yield.

7. Confidentiality and Compliance Management

- Trade Secret Protection: Require NDAs, file management, employee training, and non-public information safeguards. Examples include encrypted data transmission systems and physically isolated production zones to prevent design/parameter leaks.

- Regulatory Adherence Cases: Manufacturers must familiarize with California’s CEC energy standards, UL certifications (e.g., UL817 for plugs, UL60950-1 for adapters), and federal DOE regulations. Non-UL1581-certified cables face market entry bans; violations risk $5,000 fines per unit.

Typical Delivery Time for California Flexible Circuit Assembly

The delivery time for flexible printed circuit board (FPC) assembly manufacturers in California is typically influenced by order complexity, quantity, and priority. Standard FPC assembly bulk projects generally have a delivery period of 15 to 30 days, covering the full process from design confirmation to mass production. For urgent bulk assembly needs, some manufacturers offer expedited services with delivery times of 5 to 10 days, though this requires additional expedited fees.

For high-complexity or aerospace-grade rigid-flex printed circuit boards, the total lead time may extend to 11 to 17 weeks. This is due to the need for more rigorous testing and inspection processes, including specialized validations such as thermal cycling tests, salt spray testing, and X-ray microvia inspection.

Overall, California manufacturers balance quality assurance with flexible delivery solutions to meet diverse customer requirements. This includes adapting production schedules, optimizing manufacturing processes, and ensuring both rapid response capabilities for small-batch prototypes and stable delivery for large-scale production volumes.

How to Get A Quote For Flexible Circuit Assembly Project?

List of materials required for quotation:

- Design Files: Submit Gerber files, BOM list, circuit schematics, and 3D design models (if available) to ensure manufacturers understand circuit layout, component placement, and interface specifications.

- Material Specifications: Specify substrate type (e.g., polyimide/polyester film), thickness, copper foil thickness, surface treatment (e.g., ENIG/HASL/OSP), and solder mask color, which directly affect processing costs and process selection.

- Assembly Requirements: Clarify soldering type (SMT/through-hole/mixed), layer count, special process needs (e.g., BGA packaging, blind/buried vias, laser cutting), whether component sourcing is required, and SMT placement accuracy requirements.

- Quantity and Lead Time: Provide batch quantity, sample quantity, production batch division, and desired delivery cycle. Urgent orders must indicate urgency level (e.g., 24 hours/3 days/1 week).

- Quality and Testing Standards: Comply with IPC-A-610 standards, specify testing items (AOI inspection, X-ray inspection, functional testing), environmental certifications (RoHS/REACH), and reliability tests (e.g., thermal cycling, flex testing).

- Special Requirements: Include packaging methods (vacuum packaging/anti-static bags), shipping methods (air/ground), and special process handling (e.g., selective plating, adhesive application).

Welcome to contact us if you have any request for flexible circuit assembly project: sales@bestpcbs.com.