Taiwan PCB manufacturer plays a key role in the global electronics ecosystem, known for precision engineering and strong collaboration with international partners. This blog explores how Taiwan PCB manufacturer drives innovation in electronics, displays, and computers, and how its collaboration with leading Chinese manufacturers like EBest Circuit (Best Technology) enhances global production efficiency and reliability.

Even though Taiwan manufacturers excel in technology, you may face challenges such as:

- High cost pressure: Prototyping and small-batch orders from top-tier Taiwan suppliers can strain your budget and slow innovation cycles.

- Capacity bottlenecks: Urgent or flexible orders may be delayed due to fully booked production lines.

- Communication efficiency: Cross-region collaboration can sometimes result in slower technical support or design feedback.

- Limited attention to small orders: Low-volume projects may receive less engineering focus compared to large clients.

- Supply chain concentration risks: Relying solely on Taiwan for production increases exposure to regional disruptions.

As a Chinese PCB manufacturer specializing in PCB prototyping and SMT assembly, EBest Circuit (Best Technology) addresses these pain points with targeted solutions:

- Cost-effective production: With China’s efficient supply chain, we ensure fast, high-quality PCB delivery for prototypes and small-batch runs, keeping costs under control.

- Flexible capacity: Our agile production lines can accommodate urgent or medium-volume orders, ensuring timely project delivery.

- Efficient communication: Dedicated bilingual engineers provide one-on-one support, rapid DFM feedback, and real-time project updates.

- Equal support for small orders: High-complexity, low-volume projects receive full engineering resources, ensuring consistent quality.

- Supply chain resilience: Serving as a secondary or primary partner enables a ‚ÄúTaiwan design ‚Äď China manufacturing‚ÄĚ strategy, reducing risk and enhancing flexibility.

As an established printed circuit board factory in China, EBest Circuit (Best Technology) excel in providing outstanding quality different PCB prototype manufacturing, such as BGA PCB manufacturing, double-sided PCB, ceramic multilayer PCB, aluminum base PCB, and PCBA. We maintain core edges by offering wide variety of printed circuit boards, small batch support without MOQ, free DFM analysis, fast quoting, complete QC system and strict test means. Just feel free to send us a message via the right side of our Contact Page, or send us an email at sales@bestpcbs.com.

Taiwan PCB Manufacturer List

As a backbone of Asia’s electronics industry, Taiwan’s PCB manufacturers are globally trusted for their precision and reliability in advanced HDI and multilayer board production.

Companies such as Unimicron, Compeq Manufacturing, and Tripod Technology are at the forefront of Taiwan’s PCB industry.

- Unimicron Technology Corp.

Founded in 1990, Unimicron is a global leader specializing in HDI, rigid-flex, and substrate PCBs. The company supplies products for computers, smartphones, and automotive systems, operating advanced facilities that integrate surface treatment, micro-drilling, and plating technologies. - Compeq Manufacturing Co., Ltd.

Established in 1973, Compeq focuses on high-layer-count boards, flexible PCBs, and RF applications. With strong R&D capabilities, Compeq cooperates with major semiconductor and communication device manufacturers, maintaining strict control over copper trace uniformity and dielectric performance. - Tripod Technology Corporation

Tripod is known for its large-scale multilayer PCB production. It provides circuit boards to computing and automotive industries, with a strong emphasis on environmental sustainability and high-yield manufacturing processes.

In essence, these manufacturers reflect Taiwan’s technical depth and production strength, adhering to rigorous testing standards that meet high-speed and lead-free assembly requirements. Their diverse capabilities enable global clients to identify ideal partners across sectors, while continuous investments in automation and inspection systems sustain the worldwide supply of reliable PCBs.

Taiwan Electronics Manufacturing Companies

Taiwan’s electronics manufacturing industry is globally recognized for its efficiency and scale. Its major EMS (Electronic Manufacturing Services) providers depend heavily on the precision and quality of locally produced PCBs. Together, they form an ecosystem that drives innovation across consumer electronics, computing, and communication devices.

Leading electronics manufacturers such as Foxconn (Hon Hai Precision), Wistron Corporation, and Compal Electronics play essential roles in global product assembly and integration.

- Foxconn Technology Group (Hon Hai Precision Industry Co., Ltd.)

Foxconn is the world’s largest electronics manufacturer, assembling products for brands like Apple, Dell, and HP. The company relies on Taiwan’s PCB industry for high-performance boards used in smartphones, servers, and communication modules. - Wistron Corporation

Wistron specializes in ICT (Information and Communication Technology) products and system integration. Its partnership with local PCB suppliers allows flexible customization for notebook and IoT device designs. - Compal Electronics Inc.

Compal produces laptops, tablets, and smart devices for major global brands. By collaborating with Taiwan PCB suppliers, it achieves stable product yields and faster prototyping cycles.

In brief, these EMS companies work hand-in-hand with PCB factories to improve design manufacturability and ensure smooth transitions from prototyping to volume production. The success of Taiwan’s electronics manufacturing sector is inseparable from its PCB foundation. With close coordination between OEMs, ODMs, and PCB suppliers, the industry continues to deliver reliable and competitive solutions to global clients.

Taiwan Display Manufacturers

Taiwan’s display manufacturing sector is another pillar of its electronics economy. Known for high-resolution panels and durable optical components, display companies rely on precise PCB technology to achieve accurate signal transmission and heat management.

Key display manufacturers such as AU Optronics (AUO), Innolux Corporation, and Chunghwa Picture Tubes (CPT) represent the core of Taiwan’s display ecosystem.

- AU Optronics Corporation (AUO)

AUO is one of the world’s leading display panel producers. It uses fine-line and thermal-resistant PCBs to support LED backlight systems and power drivers in large-format displays. - Innolux Corporation

Innolux provides TFT-LCD and AMOLED solutions for TVs, automotive screens, and portable devices. Its reliance on aluminum-based PCBs enhances heat dissipation in compact modules. - Chunghwa Picture Tubes Ltd. (CPT)

Although smaller than AUO and Innolux, CPT focuses on specialized industrial displays and touch modules. It collaborates with local PCB makers to develop thin, high-signal boards for niche products.

These display manufacturers continuously innovate their PCB integration to improve reliability, energy efficiency, and optical performance.

Overall, the synergy between Taiwan’s display manufacturers and PCB suppliers keeps the island at the forefront of global display technology. By merging precision electronics with advanced materials, Taiwan continues to set new standards in visual performance and production excellence.

What Computers Are Made in Taiwan?

Taiwan has long been recognized as a hub for computer manufacturing, producing both consumer and industrial devices that are sold worldwide. The country’s PCB industry plays a crucial role in this ecosystem, ensuring that motherboards, graphic cards, and peripheral devices meet high standards of reliability and performance.

Several well-known computer brands and ODMs operate in Taiwan, relying heavily on local PCB manufacturers to support their products:

- ASUS

ASUS designs laptops, desktops, and motherboards for gaming, professional, and consumer markets. Their reliance on precise multilayer PCBs allows high-speed data transfer, stable power distribution, and thermal efficiency in compact laptop designs. - Acer

Acer produces a wide range of notebooks, desktops, and servers. Collaboration with Taiwan PCB suppliers enables Acer to implement advanced signal routing and power management features for both consumer electronics and business solutions. - MSI (Micro-Star International)

MSI specializes in gaming laptops, graphics cards, and industrial PCs. High-quality PCBs are essential for handling complex circuits and high-frequency signals, ensuring performance under heavy computational loads.

To wrap up, this close collaboration streamlines prototyping, enhances quality, and accelerates product launches, allowing Taiwanese computer makers to leverage advanced PCB technology to maintain a global competitive edge.

The Role of Taiwan PCBs in Electronics, Displays, and Computers

Across different industries, the role of PCBs remains the same ‚ÄĒ connection, signal integrity, and reliability. Taiwan PCBs have proven their strength in three main areas.

- In electronics, PCBs ensure stable current flow for smartphones, routers, and automotive control systems.

- In display modules, they help distribute power and manage temperature during continuous operation.

- In computers, they carry complex multilayer circuits that handle high-speed data transmission.

Taiwan’s experience shows how essential PCB manufacturing is for any electronic product. It also demonstrates the growing collaboration among Asian suppliers, especially with mainland China, where the speed and flexibility of production have become a new advantage.

How China and Taiwan Strengthen the PCB Supply Chain

The global PCB industry thrives on the combined strengths of Taiwan PCB Manufacturer and best PCB manufacturer in China, each playing complementary roles. Imagine manufacturing a high-end electronic product‚ÄĒlike a server or a smartphone‚ÄĒas constructing a skyscraper: Taiwan acts as the top-tier architect and supplier of critical materials, while China serves as the vast, highly efficient construction site capable of large-scale production.

Taiwan’s Strengths: Design and Key Materials

Taiwan excels in advanced technology and premium PCB materials. Leading manufacturers such as Unimicron, Zhen Ding Technology, and Tripod Technology focus on HDI boards, IC substrates, and high-frequency, high-speed PCBs. Their contribution ensures:

- Handling complex designs: Advanced PCBs for demanding applications are reliably produced.

- Maximizing performance: Products that require extreme precision and stability benefit from Taiwan’s technical depth.

China’s Strengths: Manufacturing and Scale

Mainland China complements Taiwan’s expertise with enormous production capacity, cost efficiency, and full-service manufacturing ecosystems. Advantages include:

- Cost reduction: Large-scale production lowers unit cost, improving price competitiveness.

- Speed and flexibility: From prototypes to volume orders, Chinese manufacturers deliver rapid turnaround.

- One-stop production: Regions like the Yangtze River Delta and Pearl River Delta provide complete PCB-to-SMT solutions in a single supply chain.

Among these Chinese manufacturers, EBest Circuit (Best Technology) represents a new generation of precision-driven PCB makers. By combining advanced engineering, flexible production capabilities, and a customer-focused MES tracking system, EBest Circuit (Best Technology) allows clients to leverage China’s manufacturing scale without sacrificing quality or technical expertise.

Taiwan and China reinforce the PCB supply chain in three key ways:

- Technology-Led, Manufacturing-Focused:

Taiwanese companies conduct cutting-edge R&D and pilot runs, while mass production takes place in China. With partners like EBest Circuit (Best Technology), customers can access advanced PCB technology at competitive costs and with fast delivery. - Vertical Supply Chain Integration:

Many Taiwan PCB manufacturers establish factories in China, bringing upstream suppliers like copper-clad laminates, chemicals, and equipment. EBest Circuit (Best Technology), operating within this ecosystem, ensures consistent quality and smooth coordination across all production stages. - Talent and Knowledge Exchange:

Cross-border collaboration encourages frequent movement of engineers and managers, spreading best practices across both regions. EBest Circuit (Best Technology) integrates these insights into its design and manufacturing processes, giving clients reliable results and modern engineering approaches.

Understanding these dynamics helps you make strategic decisions:

- Scenario A ‚Äď High-Performance, Complex Boards: Opt for Taiwanese manufacturers or their Chinese branches. EBest Circuit (Best Technology) can provide technical support and engineering guidance for HDI, IC substrate, or high-frequency PCBs.

- Scenario B ‚Äď Cost-Effective, High-Volume Production: Chinese PCB suppliers like EBest Circuit (Best Technology) offer speed, efficiency, and pricing advantages for consumer electronics and IoT devices.

- Scenario C ‚Äď Balanced Approach: Companies that integrate Taiwan expertise within China‚Äôs manufacturing network‚ÄĒsupported by EBest Circuit (Best Technology)‚ÄĒdeliver both sufficient technology and competitive costs.

Don‚Äôt rely on a single region. A flexible strategy‚ÄĒChina handling bulk production, Taiwan or Taiwanese-managed China factories focusing on R&D and high-end PCBs‚ÄĒcontrols costs while preserving access to advanced technology. With EBest Circuit (Best Technology) as a reliable manufacturing partner, clients can achieve both efficiency and innovation in their PCB supply chains.

EBest Circuit (Best Technology) ‚Äď Your Reliable PCB Partner in China

As a professional PCB manufacturer and assembler in China, EBest Circuit (Best Technology) provides complete solutions for global customers.

- Wide Product Offering: Our product range includes FR4 PCBs, metal core boards, ceramic substrates, and flexible circuits.

- Rigorous Quality: Every order, from prototype to mass production, follows strict quality control under ISO 9001, ISO 13485, IATF 16949, and AS9100D certifications.

- Advanced Tracking System: We integrate advanced MES systems for real-time tracking and maintain transparent production reports for every client.

- Comprehensive Technical Support: Our engineers communicate directly with customers to review design files, offer DFM guidance, and ensure manufacturability.

- Full EMS Service: EBest Circuit (Best Technology) also supports quick-turn PCB prototyping and SMT assembly, helping companies reduce development cycles and speed up market launch.

With a balanced combination of quality, speed, and competitive pricing, we have become a trusted partner for clients from electronics, automotive, medical, and aerospace industries. For global brands seeking consistent reliability and responsive service beyond Taiwan, EBest Circuit (Best Technology) is a dependable manufacturing partner from China.

Cases of Collaboration with Taiwan Clients by EBest Circuit (Best Technology)

Over the past years, EBest Circuit (Best Technology) has supported multiple Taiwanese companies across electronics and display sectors. These collaborations highlight our flexibility and engineering depth.

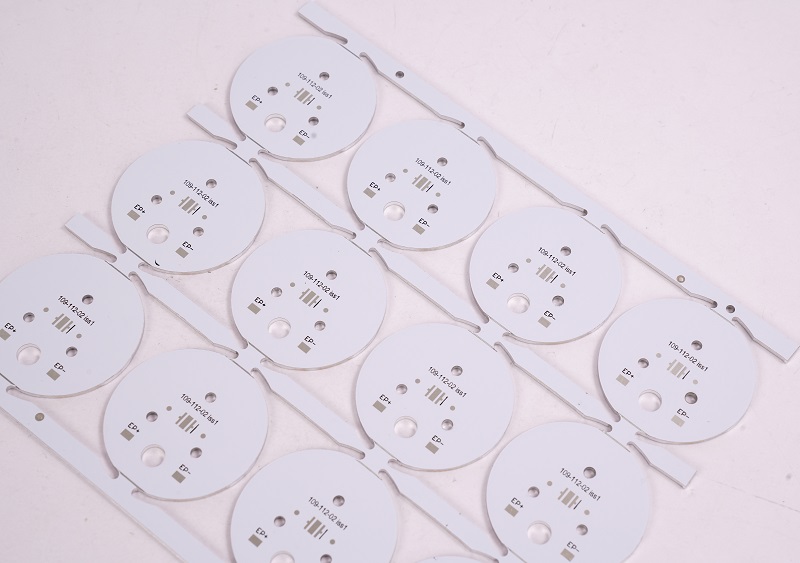

LED Display Industry: We provided aluminum-based PCBs with enhanced thermal conductivity for backlight modules, improving long-term brightness stability.

PCB Specification (Metal Core PCB)‚Äč‚Äč

- ‚ÄčBoard Type:‚Äč‚Äč Double-sided Aluminum Base (Aluminum Core PCB)Ôľõ

- ‚ÄčFinished Thickness:‚Äč‚Äč 1.6 mm ¬Ī10%Ôľõ

- ‚ÄčThermal Conductivity (Dielectric Layer):‚Äč‚Äč 1.0 W/m¬∑KÔľõ

- ‚ÄčCopper Thickness (Inner/Outer):‚Äč‚Äč 1 OZ (35 őľm)Ôľõ

- ‚ÄčSolder Mask Color:‚Äč‚Äč WhiteÔľõ

- ‚ÄčLegend/Silkscreen Color:‚Äč‚Äč BlackÔľõ

- ‚ÄčSurface Finish:‚Äč‚Äč Electroless Nickel Immersion Gold (ENIG)Ôľõ

- ‚ÄčPanel Separation:‚Äč‚Äč V-score (V-cut)Ôľõ

- ‚ÄčV-score Depth:‚Äč‚Äč 1/3 of board thickness from top and bottom (approx. 0.53mm each side)Ôľõ

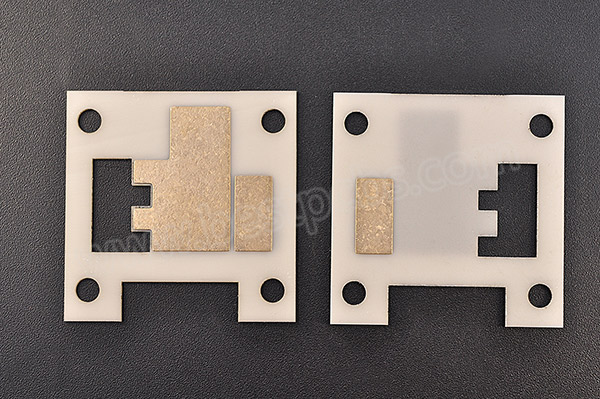

Optoelectronic Devices: Ceramic PCBs were supplied for high-temperature sensor systems used in optical control applications.

PCB Specification (AlN Ceramic Substrate)‚Äč‚Äč

- ‚ÄčMaterial:‚Äč‚Äč Aluminium Nitride (AlN)

- ‚ÄčBoard Thickness:‚Äč‚Äč 0.50 mm

- ‚ÄčPanel Size:‚Äč‚Äč 109.2 mm √ó 54.5 mm

- ‚ÄčTop Layer Cu Thickness:‚Äč‚Äč 65 ¬Ī 15 őľm

- ‚ÄčBottom Layer Final Cu Thickness:‚Äč‚Äč 200 ¬Ī 50 őľm

- ‚ÄčTop Side, 1st Layer:‚Äč‚Äč Solder Dam, Steel shim thickness 500 +50/-0 őľm

- ‚ÄčTop Side, 2nd Layer:‚Äč‚Äč Step Copper, thickness 200 +30/-0 őľm

- ‚ÄčBottom Side Solder Mask:‚Äč‚Äč Green

- ‚ÄčSurface Finish:‚Äč‚Äč Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG); Ni > 3.0 őľm, Pd > 0.05 őľm, Au > 0.05 őľm

- ‚ÄčPanelization:‚Äč‚Äč 1 Panel = 10 √ó 5 array (50 pieces per panel)

- ‚ÄčShipping:‚Äč‚Äč Panels shipped with pre-scoring (V-cut)

- ‚ÄčBow and Twist:‚Äč‚Äč < 0.8 mm

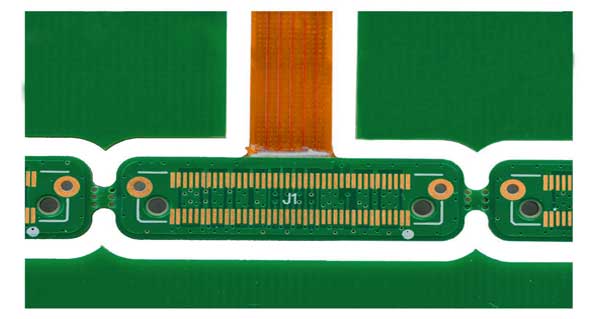

Computer Peripherals: Rigid-flex PCBs were customized for compact mechanical structures, ensuring reliable signal transmission in small form factors.

PCB Specification (Rigid-Flex PCB)‚Äč‚Äč

- ‚ÄčLayer Count/Type:‚Äč‚Äč 6-Layer Rigid-Flex PCBÔľõ

- ‚ÄčBoard Thickness:‚Äč‚Äč 1.6 mmÔľõ

- ‚ÄčCopper Weight:‚Äč‚Äč 1 OZ (35 őľm) finishedÔľõ

- ‚ÄčBase Material:‚Äč‚Äč FR-4, Tg 170¬įCÔľõ

- ‚ÄčSurface Finish:‚Äč‚Äč Electroless Nickel Immersion Gold (ENIG)Ôľõ

- ‚ÄčSolder Mask:‚Äč‚Äč GreenÔľõ

In each project, our engineering team worked closely with the client’s design department, reviewing Gerber files, optimizing copper balance, and verifying impedance before production. This collaborative workflow reduced revisions and improved first-pass yield.

Finally, Taiwan PCB Manufacturer sets a global benchmark in quality and innovation. Yet the real strength of Asia‚Äôs PCB ecosystem comes from collaboration ‚ÄĒ Taiwan‚Äôs design expertise and China‚Äôs manufacturing flexibility working side by side. EBest Circuit (Best Technology) supports clients from Taiwan and beyond with dependable PCB fabrication, fast assembly, and professional engineering support. Feel free to get in touch with us via sales@bestpcbs.com for any PCB or SMT assembly supports.

Tags: Taiwan PCB Manufacturer