Automotive copper substrate PCB 8W plays a significant role in enhancing heat dissipation and reliability in advanced automotive electronic systems. In this blog, we will discuss the definition, features, application for the automotive copper substrate PCB 8W, as well as how to choose and where to get it.

Have you faced these problems?

- Performance and reliability problems, such as poor stability in high temperatures, poor signal transmission stability, and inadequate mechanical strength

- The complexities of cost and manufacturing, such as the high difficulty of high-precision manufacturing, and the limitation of material selection

- Poor customer support and the service, such as the inferior technical support and the slow after-sales response

EBest Circuit (Best Technology) has the broad experience to tackle these issues.

- Improve the PCB performance and the reliability: apply the high-performance material, optimize the design and the process, and double test and the verification.

- Optimize the manufacturing and the cost control: employ the automation equipment to improve the production efficiency, and lower the labor costs. Besides, we will optimize the material to lower the material cost and keep the performance through material replacement and design optimization.

- Improve the customer support and the service: EBest Circuit (Best Technology) provides tailored technical service and solutions according to the customers’ requirements. Moreover, we provide quick response from our technical support team. Finally, we accumulate the customer feedback on a regular basis, aiming to improve our PCB and our service.

EBest Circuit (Best Technology) is a qualified PCB manufacturer in China, providing the automotive copper substrate PCB 8W, heavy copper PCB, aluminium core PCB, ceramic PCB, and PCB assembly service to a very large market for over 19 years. If you need an automotive copper substrate PCB 8W, just come to EBest Circuit (Best Technology) via sales@bestpcbs.com to get the wide support and the quote.

What Does Automotive Copper Substrate PCB 8W Mean?

To put it simply, the automotive copper substrate PCB 8W is specialized for automobile electricity, frequently used in high power circuits for cars, such as the LED lighting, radar, battery management system, and electric driver. Since its copper substrate could quickly dissipate the heat to ensure stability. It is known that different applications may require different copper-based PCBs. For example, the rigid copper substrate is used for vehicle-mounted fixed equipment. Whereas the flexible copper substrate is suitable for the complex wiring needs. Last but not least, ā8Wā commonly refers to the PCB heat dissipation capability (like thermal resistanceā¤8W/mĀ·K) or its rated power (like 8W/cmĀ²). The specific parameters vary from manufacturer to manufacturer.

Does Automotive Copper Substrate PCB 8W Mean Heavy Copper PCB or Aluminium Core PCB?

This is a common question. The Automotive Copper Substrate PCB 8W typically falls under the category ofĀ heavy copper PCBsĀ rather than aluminium core PCBs. The significant ways to adjust if the automotive copper substrate PCB 8W is a heavy copper PCB or an aluminium core PCB are as follows:

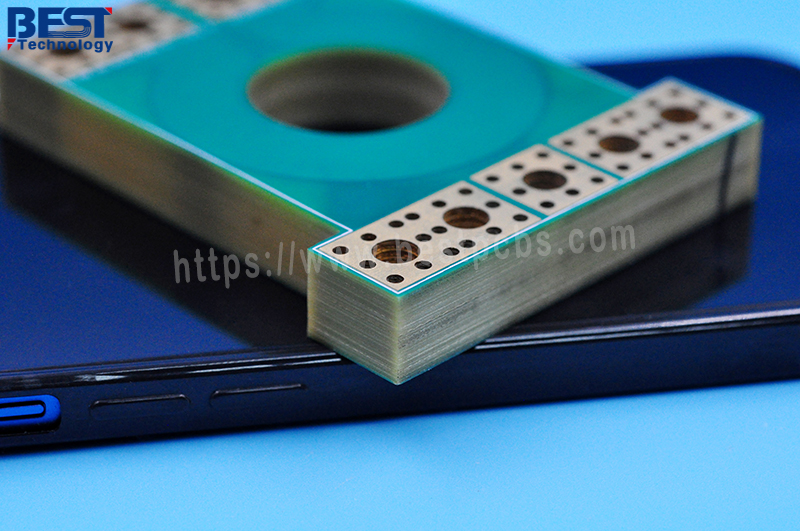

If 8W specifically refers to the copper foil thickness of 8oz, which is in the category of heavy copper PCB. If the PCB applies the aluminum substrate and the copper foil thickness up to 8W, which is a special type of heavy copper aluminum PCB. This board features include high thermal conductivity and high current-carrying capacity. These are great for some thermal management applications, but heavy copper PCBs excel in high-current environments found in many automotive power electronics. It is useful to note that if the sectional structure is a pure copper substrate, such as the copper clad laminate or aluminum substrate compound board.

So, Automotive Copper Substrate PCB 8W primarily implies a heavy copper PCB designed to meet rigorous automotive standards, rather than an aluminium core PCB.

What is the Automotive Copper Substrate PCB 8W Price?

Now, let’s discuss what factors will impact the automotive copper substrate PCB 8W price. Let’s take the MCPCB type as an example.

- First, the material and process cost plays an essential role. The metal core PCB, such as copper clad laminate, has the thermal conductivity of up to 8W/(mĀ·K), which is higher than the common FR-4 PCB board price. Besides, the circuit finness, such as 25/25Ī¼m line width and the line distance, and the layers, such as the single layer, double layer, will impact the manufacturing costs significantly.

- Another fundamental role is the application difference. The Copper-based heat sink between the automobile high-power LED lighting board and the radar/BMS PCB exists a difference. Moreover, the rigid board and the flexible board quotes are having up to 30%-50% gap.

- The final crucial factor is the marketing fluctuation and the customization. The growth rate is about 15.6% for the automobile electronic PCB market in 2025. It is important to note that bulk purchasing can lower the unit price further.

If you want to know more information about the automotive copper substrate PCB 8W price, it would be greatly appreciated if you provide the specific parameters, such as size, copper thickness, and the heat dissipation requirements. So that we could quote you the exact price.

What is the Difference Between 5 Layer PCB Stackup and 8-Layer PCB Stackup Example?

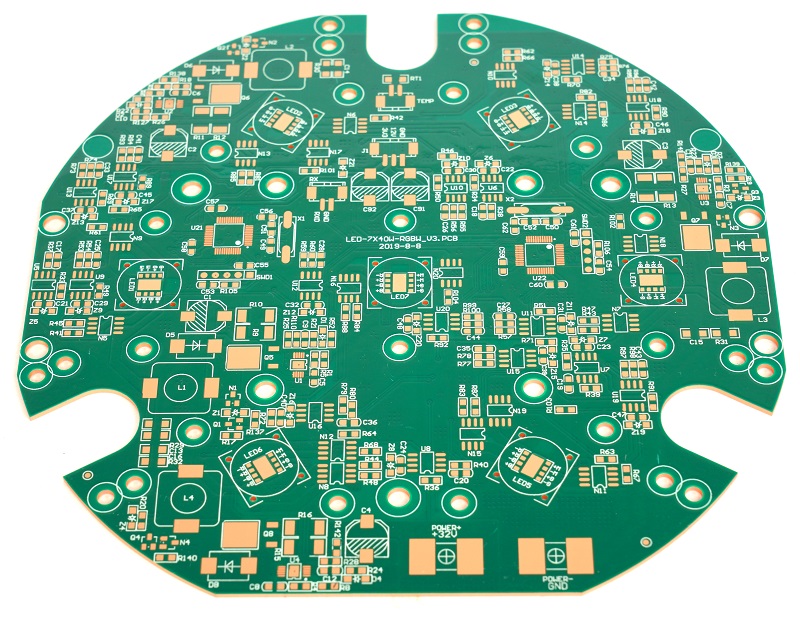

It is significant to note that the core difference between a 5-layer PCB stackup and an 8-layer PCB stackup lies in the layers, signal completeness, and the power allocation strategy.

- First, the difference in layer structure. A 5-layer PCB stackup commonly applies 3 signal layers, 1 power plane, and 1 ground plane design. It is necessary to use adjacent signal layers sharing a reference plane to realize impedance control. However, an 8-layer PCB stackup is mainly 4 signal layers, 2 power planes, and 2 ground planes, like signal1/ground1/signal2/power1/ground2/signal3/power2/signal4. Pls note that every signal layer has an independent reference plane.

- Second, the signal completeness performance. The intermediate signal layer of a 5-layer board is easily disturbed by the adjacent signal layer. And it achieves the low-loss microstrip propagation through the surface layer only. However, the 8-layer board is a through structure like signal2/ground2/signal3, to form two optimal stripline routing layers. The disturbance rate is lower than 40dB above.

- Third, the power system design. The 5-layer board is difficult to support several voltage pressure areas with the power plane only. Since the power impedance is higher. but the 8-layer double power layer can achieve zoned power distribution with 20Ī¼m heavy copper. The immediate current load is improved by 66%.

- Finally, the EMI shielded capability. A 5-layer board is only 1 complete ground plane. The high-frequency radium is weak. Whereas the 8-layer has a 3-ground plane design, such as ground1/power1/ground, which achieves the Faraday cage effect, enhancing geomagnetic absorption capacity by 300%. The extra layers in an 8-layer PCB enable better control of electromagnetic interference (EMI) and allow for higher-speed signal routing. For automotive copper substrate PCB 8W designs, this is often essential to manage heat and power delivery in high-performance modules.

How to Choose the PCB Material for High Temperature?

Common choices for automotive copper substrate PCB 8W include heavy copper substrates paired with advanced epoxy or ceramic-based laminates. It is interesting to know how to choose the PCB material for high temperatures. Here, I will take the automotive copper substrate PCB 8W as a case. There are 3 aspects we would like to discuss.

- The first basic role is the heat conductivity coefficient requirement. The automotive copper substrate PCB 8W should choose the dielectric layer material whose heat conductivity coefficient is over 3.0W/mK. And it is critical to note that the heat conductivity coefficient could be up to 200W/mK if using the ceramic(like AIN) to fill the aluminum substrate board. And the copper layer thickness is recommended to be over 2oz, which, if working together with over 1.5mm aluminum substrate, will achieve the heat dissipation effectively.

- The second factor is the heat-resistance grade match. If in the engine compartment environment, the long-term operation temperature of the board’s material needs to be over 150āļ¼ and the short-term operation temperature should be up to 300ā (such as the urgent speed work situation)

- Finally, the main factors are vibration reliability and electrical insulation assurance. First, the material should pass the reliability test at random, such as the 20G mechanical shock test and the 10-2000Hz random vibration verification. Second, to ensure the electrical insulation, we recommend using the UL94V-0 flame-retardant grade materials.

Where is Automotive Copper Substrate PCB 8W Used?

Automotive Copper Substrate PCB 8W finds applications across various automotive sectors, particularly in power electronics and thermal management areas:

- Battery management system (BMS): This is an innovative application. In the electrical car batteries, an 8W copper substrate PCB is used to get the modules of the current sensor circuit. It is noted that the premium copper electrical conductivity ensures the sampling precision.

- Smart Cabin System: The automobile infotainment motherboard of the GPU heat dissipation module adopts the compound structure of the copper substrate and the vapor chamber, which tackles the problem of 4K monitor heat dissipation.

- High-power automobile lighting: The copper substrate is designed for LED lighting, which can avoid lumen depreciation through a thermal conductivity of 8W/mK, managing the heat generated by high-brightness lighting.

Where to Get the Best Automotive Copper Substrate PCB 8W?

EBest Circuit (Best Technology) has provided high-quality automotive copper substrate PCB 8W to a very strong market for over 19 years.

- Full Turnkey Support: We have a strong R&D team to tackle your technical problems throughout the entire EMS turnkey manufacturing process, such as high-temperature PCB material procurement, prototypes, fabrication, assembly, box build, and final delivery.

- Fast Delivery: With our fast delivery policy, we will proceed with your order and shorten the lead time within 2-3 weeks, no matter how complex your metal core PCB board is.

- Great Prompt service: No matter when you sent the inquiry or technical questions to us, we will find a way to give you a quick response. Our sales team is not a message sender; they are semi-engineers. We can give you professional and fast support.

- Certified factory: EBest Circuit (Best Technology) is an original manufacturer of metal core PCB, heavy copper PCB, and ceramic PCB. Our PCB profile is abroad to meet your different project needs and provide our viable solutions. Our factory is fully compatible with ISO 9001, ISO 13485, IATF 16949, AS9100D, UL, REACH, and RoHS. There is no need to worry that your boards are being manufactured by an unstandardized factory.

All in all, understanding what is the automotive copper substrate PCB 8W is greatly helpful when doing the related projects. EBest Circuit (Best Technology) helps a variety of customers tackle different issues for their automotive PCB projects. We welcome inquiries to discuss your unique PCB needs and help you find the optimal automotive copper substrate PCB 8W solution. Just send us an email at sales@bestpcbs.com.