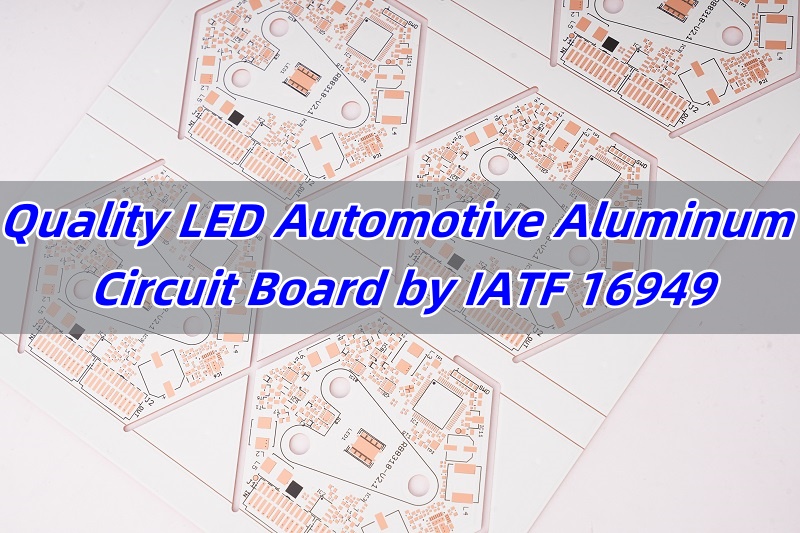

Led automotive aluminum circuit board is the first thing many engineers look for when designing reliable and high-efficiency vehicle lighting systems. These boards are not just about conducting electricityâthey solve real problems like heat buildup, limited space, and unstable performance. In todayâs automotive world, especially with the rise of EVs and smart lighting, stable and durable LED PCBs have become a core need. But not all suppliers can meet the strict quality, price, and delivery expectations of global buyers. With IATF 16949 certification and a strong focus on engineering support, EBest Circuit (Best Technology) helps customers avoid delays, reduce complaints, and achieve long-term success in a competitive market.

EBest Circuit (Best Technology) supplies quality LED automotive aluminum circuit board services to the more competitive market since 2006. You feel assured that each manufacturing process from our factory is in line with the IATF 16949. We gain the competitive edge by maintaining consistency in design, material procurement, prototype, fabrication, PCBA, inspection, and after-sales service.

We have the cutting-edge aluminum printed circuit boards manufacturing equipment and the technical capability, which will meet your multilayer, high-density, and high thermal dissipation performance needs. Reliability testing support includes thermal shock testing, vibration testing, solder joint strength testing, corrosion resistance testing, AOI, and X-ray to ensure long-term stability of products in harsh automotive environments. Pls send us an email at sales@bestpcbs.com for new questions or other support required.

What is LED Automotive Aluminum Circuit Board?

Led automotive aluminum circuit board refers to a specialized PCB used in vehicle lighting and electronic systems. It uses an aluminum core as the base material, known for its superior thermal conductivity. The typical structure includes three layers: a copper circuit layer, a thermally conductive insulating layer, and a solid aluminum base. This design helps quickly transfer heat away from high-power LEDs, protecting components and ensuring stable performance under continuous use.

In automotive applications, especially under the hood or near lighting systems, reliability is critical. Thatâs why these boards must meet strict automotive-grade standards, such as IATF 16949, to ensure they can withstand high temperatures, strong vibrations, and prolonged operation. Besides excellent heat dissipation, aluminum PCBs also offer good mechanical strength and corrosion resistance, making them ideal for use in headlights, control modules (ECUs), and other demanding environments found in vehicles.

What are the Features of LED Automotive Aluminum Circuit Board?

These boards offer several benefits. They are lightweight, durable, and resist vibration. Thermal management is a major strength. With better heat dissipation, they reduce overheating risks. Their structure supports high-brightness LED chips which are common in headlights and tail lamps.

What is the Led Automotive Aluminum Circuit Board Price?

The cost of a led automotive aluminum circuit board is influenced by several key factors:

- Layer Count, Size, and Surface Finish

- Basic elements that affect the base cost of the board.

- Aluminum Base Material

- Common grades like 5052 or 6061.

- Higher-grade aluminum offers better strength and corrosion resistance.

- Thermal Conductivity of the Dielectric Layer

- Standard values range from 1.0 to 3.0W/m·K.

- Higher conductivity ensures better heat dissipation but adds to cost.

- Automotive-Grade Compliance

- IATF 16949 certification increases reliability, with added cost for compliance.

- Copper Foil Thickness

- Typically 1oz or 2oz; thicker copper improves current capacity and thermal performance.

- Circuit Design Complexity

- High-frequency signals and fine-pitch layouts require tighter tolerances and increase production difficulty.

- Board Structure

- Multi-layer boards with advanced stack-ups are more expensive than simple single-layer types.

- Production Volume

- Large-volume orders offer better pricing per unit compared to low-quantity prototypes.

Finally, a basic single-layer board using standard materials can cost below $1 per piece in bulk. Complex or multi-layer automotive-grade PCBs with strict specs will cost more depending on requirements. At EBest Circuit (Best Technology), we go beyond pricing transparency. Every quote includes design-for-manufacturing (DFM) review to help you avoid costly errors early in the process. We also perform essential reliability testingâsuch as thermal shock, vibration resistance, and solderability checksâto ensure long-term performance in harsh automotive environments. Whether you’re ordering prototypes or full production runs, our pricing reflects quality, safety, and thoughtful engineering built into every board.

How Many Aluminium PCB Board for LED are in a Car?

The number of LED aluminum PCBs in a car varies based on the type and configuration of the vehicle:

- Traditional Fuel Vehicles

- Typically use 8 to 15 aluminum PCBs.

- Common applications include:

- Headlights

- Tail lights

- Daytime running lights

- Turn signals

- Fog lamps

- Dashboard backlighting

- Electric Vehicles (EVs)

- Require more than 20 boards in many cases.

- Additional boards are used in systems like:

- Battery Management System (BMS)

- Internal lighting modules

- Display units and digital clusters

- High-End or Premium Vehicles

- May include 2 to 3 extra control boards.

- These support advanced functions such as:

- Adaptive high beam systems

- Matrix LED lighting

- Smart lighting control linked to vehicle sensors

As automotive technology evolves, both the quantity and complexity of LED aluminum PCBs continue to growâespecially in EVs and intelligent lighting systems.

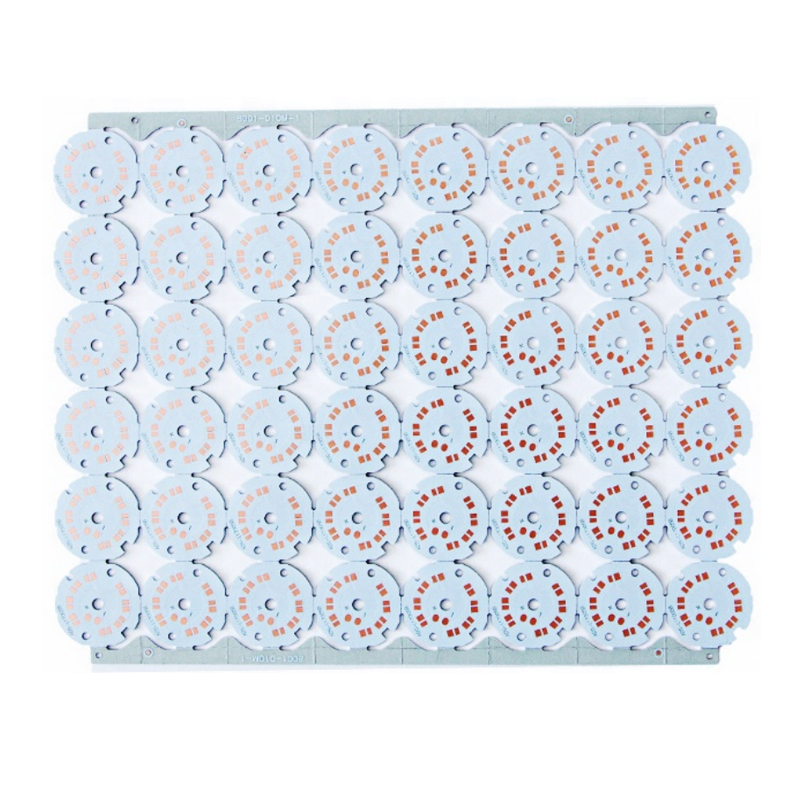

Does the Color of an Aluminum Circuit Board Matter?

Yes. White solder mask is widely used in LED lighting. It reflects light better and gives consistent color tone. Though colors donât impact function, the right choice supports design and visual appeal. EBest Circuit (Best Technology) offers various mask colors for your needs.

How to Make an Aluminum Foil Circuit Board?

Creating an aluminum foil circuit board at home is a feasible DIY method for low-voltage, low-current prototypes or educational projects. However, it’s important to understand its limitations and that it’s not suitable for automotive or high-reliability use. Hereâs a basic step-by-step process:

- Materials Required:

- Thin aluminum foil (e.g., kitchen-grade foil, ~0.02mm thick)

- Adhesive (such as spray glue or epoxy resin)

- Insulating substrate (commonly cardboard, plastic sheet, or FR4 board)

- Permanent marker or etch-resistant pen

- Etching solution (such as a sodium hydroxide solution or hydrochloric acid mixtureâused with extreme caution)

- Procedure:

- Clean and dry the insulating substrate thoroughly.

- Apply adhesive evenly and press the aluminum foil onto the surface without wrinkles.

- Draw the circuit pattern using a permanent marker, leaving only the traces you want to keep.

- Submerge the board in the etching solution to remove excess foil.

- Rinse and dry the board, then check continuity with a multimeter.

- Limitations:

- Current capacity is very low due to foil thickness (usually <0.03mm).

- Heat resistance is poor, as kitchen foil lacks the durability of industrial copper or aluminum-clad laminates.

- Precision is limited, making it unsuitable for fine-pitch components or multi-layer layouts.

- Why Itâs Not for Automotive Use:

- Automotive environments demand high thermal conductivity, mechanical strength, and vibration resistance.

- Certified materials and processes like those used in IATF 16949-compliant aluminum PCBs are required to meet safety and reliability standards.

- DIY boards canât provide traceability, consistent dielectric strength, or verified insulation resistance.

So while aluminum foil circuit boards are great for learning or very simple circuits, they cannot replace engineered aluminum PCBs in critical fields like automotive, medical, or industrial applications.

How to Ensure the Quality When Doing LED Circuit Board Replacement?

Ensuring quality during LED circuit board replacement requires careful attention to several critical steps:

- Check Part Compatibility

- Verify that the replacement board matches the original in size, layout, and electrical specifications.

- Confirm component footprints and connector types to avoid misfits or connection failures.

- Avoid Overheating During Desoldering

- Use temperature-controlled soldering tools to prevent damage to the PCB and nearby components.

- Apply heat only as long as necessary to avoid warping or delamination of the board.

- Clean the Pads Thoroughly

- Remove residual solder, flux, and contaminants from the pads before installing the new board.

- Proper cleaning ensures good solder joint formation and reliable electrical contact.

- Use High-Quality Replacement Boards

- Choose replacement PCBs from trusted suppliers like EBest Circuit (Best Technology), which provide boards tested to meet automotive standards such as IATF 16949.

- Such boards undergo rigorous quality control and reliability testing, ensuring long-term performance.

- Post-Installation Inspection

- After replacement, perform visual and electrical inspections to confirm solder joint integrity and functional correctness.

- Testing under real operating conditions helps verify the boardâs performance before full deployment.

Following these steps helps avoid common pitfalls such as poor solder joints, component failure, or premature board degradation. Partnering with experienced manufacturers ensures your replacement LED circuit boards maintain the reliability required in demanding automotive environments.

Why Should You Choose EBest Circuit (Best Technology) as Your Reliable Aluminum Printed Circuit Boards Supplier?

At EBest Circuit (Best Technology), we understand how delays and poor quality can hurt your business. Thatâs why we offer:

- Quick Response:Â Fast quotes and engineering feedback to keep your projects moving. Any inquiries or technical problems will be answered within 4 hours. Our engineering and sales teams are always available to assist you 24/7.

- Certified Quality:Â Our IATF 16949, ISO 9001, ISO 13485, AS9100D certification means full control over automotive production processes.

- Traceability:Â MES systems track every step. Youâll always know what happened and when.

- Custom Support:Â From single-layer to complex multilayer boards, we tailor solutions to meet your goals.

- Stable Delivery:Â Whether itâs prototypes or volume production, we deliver on time with strict quality control. EBest Circuit (Best Technology) has a high on-time delivery rate of up to 97%.

Many clients switch to us after facing poor response and inconsistent quality from other suppliers. We work to solve that problemâone board at a time.

In summary, the led automotive aluminum circuit board is a key part of modern vehicle electronics. Its thermal performance and durability help automotive LEDs shine longer and brighter. If you need a reliable, professional partner to handle your LED PCB needs, EBest Circuit (Best Technology) is here. We help you avoid delays, miscommunication, and poor quality. Reach out to us at sales@bestpcbs.com for any further inquiry or support.