In high-power electronics, heat management is one of the most important factors for ensuring long-term performance and reliability. When components operate at high temperatures, efficiency drops, solder joints weaken, and overall lifespan shortens. This is where Direct Thermal Path (DTP) Copper PCBs come in — they channel heat away from components quickly and efficiently.

However, the performance of a DTP PCB depends not only on its core structure but also on the surface finish. One popular choice is immersion tin, a cost-effective, lead-free finish with excellent solderability. In this article, we’ll explore what immersion tin is, how it works with thermal path copper PCBs, and why it’s worth considering for your next high-power design.

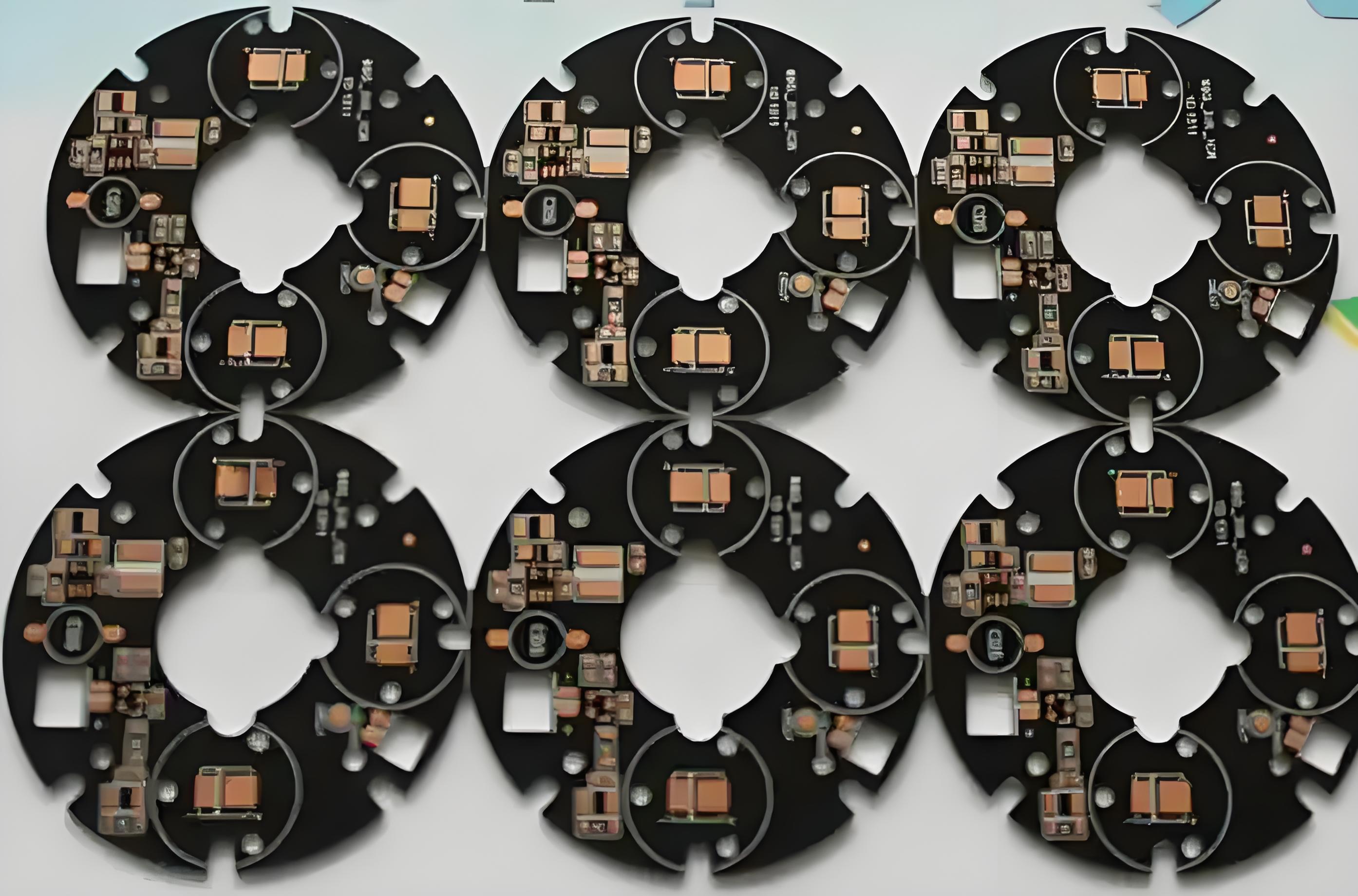

Immersion Tin Direct Thermal Path Copper PCB

What is Immersion Tin Surface Finish?

Immersion tin is a metallic coating applied over the exposed copper areas of a PCB. Its primary purpose is to protect copper from oxidation before soldering and to provide a smooth, solder-ready surface.

Unlike hot air solder leveling (HASL), which deposits solder on copper pads, immersion tin uses a chemical displacement process. During manufacturing, the copper surface is immersed in a chemical bath containing tin ions. The tin replaces the copper atoms at the surface, creating a thin, uniform coating — typically 0.8–1.2 micrometers thick.

Key characteristics of immersion tin:

- Lead-free and RoHS compliant, meeting environmental standards.

- Flat and smooth surface — ideal for fine-pitch components.

- Good shelf life when stored in controlled conditions.

- Uniform coating even on small pads and vias.

Because it’s applied chemically, immersion tin creates a consistent and even finish across the PCB, which is important for solder joint quality in DTP designs.

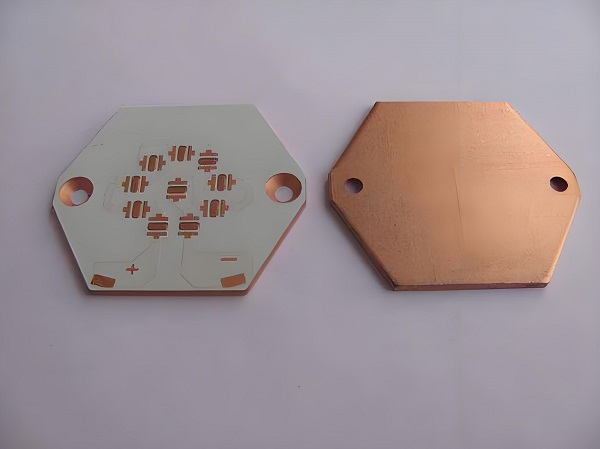

What is Direct Thermal Path Copper PCBs?

A Direct Thermal Path PCB is designed to give heat a straight path from heat-generating components to a metal base, usually copper or aluminum.

In a standard FR4 PCB, heat has to travel through dielectric layers before reaching a heat sink, which slows down dissipation. In a DTP design, thermal vias and copper cores bypass most of the insulating material, providing a low-resistance path for heat flow.

Typical DTP PCB structure:

- Copper circuitry layer for electrical connections.

- Dielectric layer with high thermal conductivity.

- Copper core or base acting as the main heat spreader.

- Thermal pads directly under high-power components.

This is especially useful for LED lighting, power electronics, and automotive modules, where thermal management is critical.

What is Direct Thermal Path Copper PCBs?

Advantages of Immersion Tin for Thermal Path PCBs

When you combine a DTP PCB with an immersion tin surface finish, you get a unique balance of thermal performance and solder reliability.

- Immersion tin bonds well with solder, creating strong and consistent joints — essential for high-reliability assemblies.

- Ideal for fine-pitch ICs and surface mount components, where accurate placement matters.

- Even on complex copper geometries, the tin layer is consistent, preventing uneven soldering.

- Maintains low contact resistance for both electrical signals and heat conduction.

- Fully meets RoHS environmental requirements.

- More affordable than ENIG (Electroless Nickel Immersion Gold) while still offering high performance.

Our Immersion Tin Thermal Path PCBs

| Item | Parameter |

| Board Thickness | 1.6mm |

| Copper Thickness | 2OZ |

| Solder Mask | White |

| Thermal Conductivity | 398W/m.k |

| Voltage Resistance | AC2500-4000V |

| Testing | AOI & 100% open/short testing |

| Lead Time | 7-8 days for prototype |

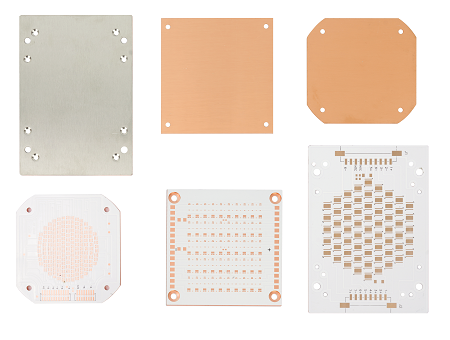

DTP PCB Design and Manufacturing

Designing and manufacturing Direct Thermal Path PCBs with immersion tin involves careful material and process choices.

1. Material Selection

- Copper core thickness can range from 0.5 mm to several millimeters, depending on the heat load.

- The dielectric must have high thermal conductivity (2–8 W/m·K or higher).

2. Thermal Simulation & Layout

- Engineers place components so that heat flows directly to the copper base.

- Thermal vias may be added under components to enhance the path.

3. Drilling and Plating

Mechanical drilling or laser drilling creates precise holes for both electrical and thermal transfer.

4. Applying Immersion Tin

After etching the copper circuitry, the exposed pads are cleaned and immersed in a tin bath.

This step happens late in the process to prevent oxidation before shipment.

Direct Thermal Path PCB Applications

DTP PCBs with immersion tin are used in industries where both high thermal performance and strong solderability are important:

- High-Power LEDs — Street lighting, stage lighting, and automotive headlights.

- Power Supply Modules — DC-DC converters, AC-DC adapters.

- Motor Controllers — Industrial automation and robotics.

- RF Power Amplifiers — Heat-sensitive high-frequency components.

- Electric Vehicles — Battery management systems (BMS) and onboard chargers.

By providing a direct copper heat path, these PCBs keep components cooler and extend their lifespan.

Comparing Immersion Tin with Other Surface Finishes

| Surface Finish | Solderability | Shelf Life | Cost | Thermal Path Suitability |

| Immersion Tin | Excellent | 6–12 months | Medium | Very Good |

| HASL (Lead-free) | Good | Long | Low | Fair |

| ENIG | Excellent | 12+ months | High | Excellent |

| OSP | Good | 6 months | Low | Good |

| ENEPIG | Excellent | 12+ Months | Higher | Excellent |

Immersion tin offers a strong middle ground — better performance than OSP or HASL for DTP boards, at a lower cost than ENIG.

EBest Circuit (Best Technology) – Your Reliable Direct Thermal Path PCB Partner

At EBest Circuit (Best Technology), we specialize in high-quality direct thermal path copper PCBs with immersion tin surface finish. Our advanced manufacturing lines ensure precise copper layering and uniform tin plating, delivering PCBs that meet stringent thermal and mechanical standards.

We provide:

- Custom DTP PCB design support

- State-of-the-art immersion tin plating

- Rigorous quality assurance, including thickness measurement and solderability testing

- Full RoHS and environmental compliance

- Expert customer service and flexible order volumes

Trust EBest Circuit (Best Technology) as your go-to partner for reliable, high-performance thermal path PCBs.

FAQs

Q1: What is the typical lifespan of an immersion tin surface finish?

A1: With proper storage, immersion tin surface finish can maintain solderability for up to 6 months, though this varies with storage conditions such as humidity and temperature.

Q2: Can immersion tin be used for high-frequency PCBs?

A2: Yes, immersion tin provides a smooth, flat surface ideal for high-frequency signals, minimizing signal loss and ensuring reliable connectivity.

Q3: How does immersion tin affect thermal conductivity?

A3: The tin layer is very thin (usually less than 0.5 microns), so it has minimal impact on the copper’s thermal conductivity, maintaining efficient heat dissipation.

Q4: Is immersion tin surface finish lead-free?

A4: Yes, immersion tin is a lead-free surface finish and complies with RoHS regulations, making it environmentally friendly.

Q5: What are the storage requirements for PCBs with immersion tin finish?

A5: PCBs should be stored in a clean, dry environment, preferably sealed with desiccants to minimize oxidation and prolong shelf life.

Tags: direct thermal path copper pcb, immersion tin copper pcb