Why choose double sided aluminum PCB for motor? Let’s discover its benefits, application, design guide, thermal solution, cost and quality balance methods.

Are you worried about these issues?

- Is sustained high temperature causing a shortened motor lifespan?

- Traditional PCBs have poor heat dissipation, making efficiency difficult to achieve?

- Double-sided device layouts are complex, causing heat dissipation conflicts?

EBest Circuit (Best Technology) can provide solutions:

- Double-sided aluminum substrate with three-dimensional heat dissipation (aluminum substrates conduct heat from both sides, increasing heat dissipation efficiency by 60%)

- Highly thermally conductive insulation layer design (middle layer material withstands temperatures up to 180Ā°C, preventing heat accumulation)

- Optimized copper layer via arrays (increases vertical heat conduction speed by three times, resolving layout conflicts)

Welcome to contact us if you have any request for aluminum PCB: sales@bestpcbs.com.

Why Choose Double Sided Aluminum PCB for Motor?

Reasons why choose double sided aluminum PCB for motor:

āSuperior Heat Dissipationā

- Aluminum cores (e.g., 6061/5052 alloys) provide ā200W/mK thermal conductivityā, preventing overheating in high-power motor drivers.

- ā50% lower thermal resistanceā vs. FR4, ensuring stable performance under heavy loads.

āEnhanced Mechanical Durabilityā

- Matched CTE with motor components reduces āthermal stress fracturesā.

- ā30% higher bending strengthā than ceramic substrates, ideal for vibration-prone environments.

High-Density Circuit Designā

- Double-sided wiring via āvia metallizationā increases component density by ā60%ā compared to single-layer boards.

- Supports āfine-line etching (0.05mm)ā for complex motor control circuits.

āCost-Effective for High-Power Applicationsā

- Eliminates the need for bulky heatsinks, cutting āassembly costs by 20%ā.

- āLonger lifespanā in harsh conditions (e.g., EVs, industrial motors).

Signal Integrity Boostā

- Ā±5% impedance controlā minimizes EMI in PWM-sensitive motor control signals.

- Low dielectric constant (Īµr~4.5) ensures stable high-frequency performance.

Applications of Double Sided Aluminum PCB in Motor

- High-Efficiency Motor Drives: Enables 98%+ power conversion efficiency in BLDC/PMSM controllers via low-loss copper traces and thermal management.

- Electric Vehicle (EV) Traction Systems: Withstands 200Ā°C+ peak temperatures in inverter modules under continuous 100kW+ load. Such as Tesla Model 3ās motor controller adopts similar Al PCB for 30% smaller form factor.

- Robotics & Automation: Vibration-resistant design ensures stable operation in robotic joints (e.g., UR10eās 6-axis motors).

- Renewable Energy Motors: Wind turbine pitch control systems leverage Al PCBās UV resistance for outdoor reliability. Such as solar tracking motors show 20% longer MTBF with Al PCB.

- Aerospace & Defense: MIL-PRF-55182 certified for extreme environments (e.g., drone motor controllers at -55Ā°C~125Ā°C).

Motor Double Sided Aluminum PCB Design Guide

1. Requirement Analysis & Specification Lock

- Current/Voltage Mapping: Identify high-current zones (e.g., IGBT/MOSFET arrays) and voltage isolation needs.

- Thermal Profile: Define max operating temp (e.g., 125Ā°C for automotive ECUs) and ambient cooling.

- Space Constraints: Measure enclosure dimensions for PCB stacking (e.g., BLDC motor height <50mm).

2. Material Selection & Stack-up Design

Aluminum Core:

- Thickness: 0.5mm (compact motors) to 3.2mm (EV inverters).

- Coating: Anodized (corrosion resistance) or Ni-plated (solderability).

Dielectric Layer:

- High-Tg EpoxyĀ (Tg=170Ā°C, cost-effective for <100A).

- Low-Loss PTFEĀ (Dk=2.2, ideal for >200kHz PWM).

3. Layout Design: Thermal + Electrical Optimization

Thermoelectric Separation:

- Place power traces on top layer, thermal pads on bottom layer.

- Avoid crossing high-current paths with control signals.

Via Design:

- Thermal Vias: Laser-drilled (0.3mm diameter, 1.0mm pitch) under hot components.

- Stitching Vias: Connect ground planes to aluminum base (ā„5 vias/cmĀ²).

4. Manufacturing & Assembly Considerations

- Solder Mask Clearance: ā„0.2mm from aluminum edges to prevent mask cracking.

- Paste Stencil Design: Thicker stencil (0.15mm) for large ground pads.

- Wave Soldering: Avoid aluminum exposure to solder flux (use nitrogen atmosphere).

5. Testing & Certification

- Thermal Cycling: -40Ā°C to 150Ā°C, 100 cycles (ISO 16750-4).

- EMC Compliance: CISPR 11 radiated emissions (for medical/automotive).

- Vibration Resistance: 5ā500Hz, 2hrs (IEC 60068-2-6).

Motor Double Sided Aluminum PCB Thermal Solution

1. Material Selection and Structural Optimization

- Double-Sided Aluminum PCB Design: A double-sided aluminum cladding structure (adjustable thickness 0.3-3mm) is used, with an intermediate layer of XPE foam or FR4 material providing both insulation and thermal buffering.

- Copper Layer Thickness: 1oz/2oz copper layers are recommended. Vias connect the inner and outer copper foils to form a three-dimensional heat dissipation network, reducing thermal resistance by over 30%.

- Surface Treatment: Hot Air Leveling (HAL) or Organic Solderability Preservative (OSP) processes are preferred to prevent heat dissipation degradation caused by silver migration.

2. Heat Dissipation Path Design

- Double-Sided Liquid Cooling Integration: Drawing on automotive power module technology, coolant channels are reserved on the back of the PCB. This dual-sided heat dissipation improves thermal density by 40%.

- Thermal Via Array: 0.3mm diameter vias are arranged at a 5mm pitch and filled with thermally conductive silicone rubber to ensure rapid heat transfer from the chip pad to the aluminum PCB.

- Copper Foil Extension: A star-shaped copper plating design is used around the motor driver IC, with trace widths increased according to IPC-2221 standards (7mm width required for 10A current).

3. Manufacturing Process Control

- Lamination: Vacuum lamination technology is used to ensure bubble-free contact between the aluminum substrate and the insulation layer, with a thermal conductivity of ā„2.0W/mĀ·K.

- Laser Cutting: UV laser shaping is used to eliminate burrs, ensuring a heat dissipation surface flatness of ā¤0.1mm.

- Temperature Rise Testing: Full-load operating conditions are monitored using an infrared thermal imager, with a temperature rise of ā¤25Ā°C for key components.

Motor Double-Sided Aluminum PCB Quality-Cost Optimizationā

- Material Tieringā: Use standard-grade aluminum (6061) for low-power applications and premium alloys (7075) for high-performance motors, reducing material costs by 15-20% without compromising thermal performance.

- Via Optimizationā: Standardize via sizes to 0.3-0.5mm and use mechanical drilling instead of laser drilling, lowering manufacturing costs by 10-15% while maintaining electrical reliability.

- Surface Finish Selectionā: Prioritize OSP (Organic Solderability Preservative) over ENIG (Electroless Nickel Immersion Gold) for cost savings of 30-40%, with proven solderability for motor control applications.

- Design for Testability (DFT)ā: Integrate test points during layout to minimize post-production testing time, reducing QA costs by 20% without sacrificing defect detection rates.

- Thermal Management Efficiencyā: Use staggered thermal via patterns instead of dense arrays, achieving 25% better heat dissipation with 15% fewer vias, saving fabrication time and material.

- Bulk Component Sourcingā: Partner with suppliers for standardized capacitor and resistor values, reducing procurement costs by 10-20% through volume discounts.

- Automated Optical Inspection (AOI)ā: Implement AOI at critical process steps to catch defects early, reducing rework costs by 30% and improving yield.

- Layer Stack Simplificationā: Use 2-layer designs wherever possible instead of 4-layer, cutting material and lamination costs by 25% for non-critical motor control circuits.

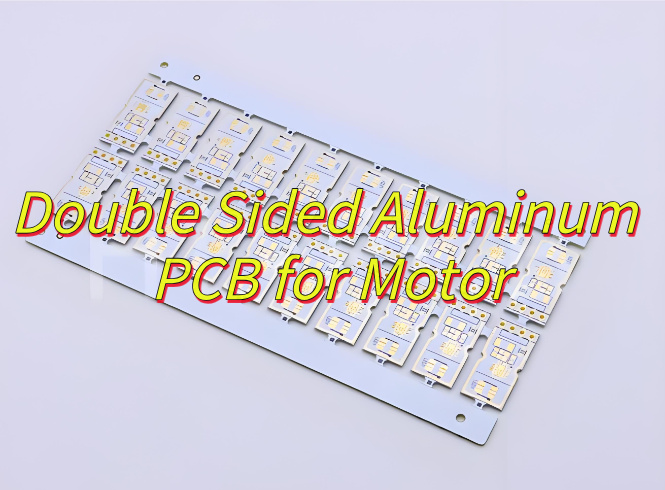

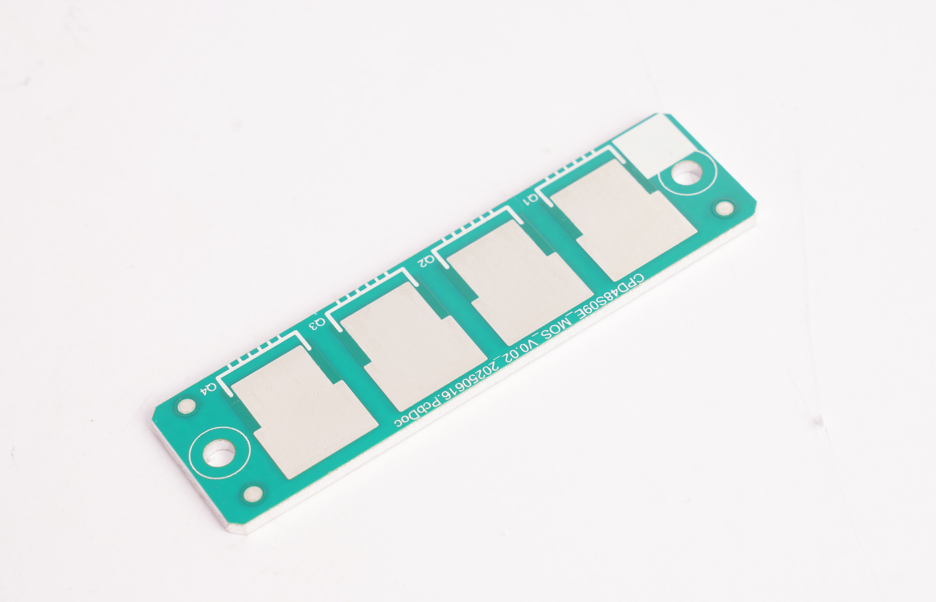

Our Motor Double Sided Aluminum PCB Case Studies

At EBest Circuit (Best Technology), we have been deeply engaged in the motor double-sided aluminum PCB field for 19 years, successfully delivering hundreds of motor aluminum PCB projects. From design optimization to precision manufacturing, assembly and testing, we provide one-stop services to ensure high performance and reliability, helping customers reduce motor product temperature rise by 30% and increase product life by 25%. Here is a photo of our motor double sided aluminum PCB case:

| Product Nameā | Ā Motor Double-Sided Aluminum PCB |

| Base Layer Ā | 1060 Aluminum Alloy |

| Copper Foil Ā Ā | 1oz (35Ī¼m) Electrolytic Copper (Double-Sided) |

| Thicknessā | 1.6mm (Ā±0.1mm) |

| Solder Maskā | White Solder Mask (High Temperature Resistance, 260ā/10s) |

| Marking | Silk-Screen Marking (Black, Minimum Line Width: 0.15mm) |

| Surface Finish | HASL (Lead-Free) |

| Key Processes | Laser Drilling (Min. Hole Diameter: 0.2mm) |

| ApplicationsāĀ Ā Ā Ā | Motor Drivers (Industrial & Automotive) |

Why Choose EBest Circuit (Best Technology) as Aluminum PCB Manufacturer?

- Ultra-High Current Capacity: Supports 100ā800A+ currents (EV inverters, industrial drives) via 2ā4oz copper layers. Eliminates 2ā3 FR-4 PCB layers, cutting costs by 30% and space by 40%.

- Exceptional Thermal Conductivity: Aluminum core (200+ W/mK) dissipates heat 10x faster than FR-4. Reduces component junction temps by 35ā45%, extending motor lifespan to >50,000 hours.

- Precision Signal Integrity: Low-loss PTFE dielectric (Dk=2.2ā3.5) ensures clean PWM signals up to 500kHz. Passes EMC standards (CISPR 11) without additional shielding, savingĀ 500ā1,500 per unit.

- Vibration & Shock Resistance: CTE-matched design (23 ppm/Ā°C) prevents solder joint fatigue. Survives 5ā500Hz vibration tests (IEC 60068-2-6), reducing field failures by 60%.

- Cost-Effective Scalability: 30% cheaper than ceramic substrates at similar performance. Lowers prototyping costs byĀ 2,000ā5,000, accelerating R&D cycles.

- ISO-Certified Compliance: Pre-qualified for automotive (IATF 19649) and medical (ISO 13485) standards. Exempts secondary testing, cutting compliance costs by 30% and time by 50%.

- Free DFM Optimization: AI-driven layout analysis flags trace spacing, via placement, and material mismatches. Reduces redesigns by 80% and material waste by 25%.

- Rapid Prototyping (24-Hour Turnaround): In-house laser drilling and plating lines enable same-day fabrication. Shortens R&D cycles by 50%, accelerating time-to-market by 4ā6 weeks.

Welcome to contact us if you have any request for aluminum PCB: sales@bestpcbs.com.