What Is a UV LED Circuit Board?

A UV LED circuit board is a specially engineered printed circuit board designed to mount, power, and cool ultraviolet light-emitting diodes (UV LEDs). Unlike visible-light LEDs, UV LEDs emit light in the ultraviolet spectrum, typically between 200nm and 400nm, and are divided into:

- UV-A (315–400nm) – Used in curing, fluorescence, counterfeit detection.

- UV-B (280–315nm) – Used in medical therapy and photobiology.

- UV-C (200–280nm) – Used in sterilization and germicidal applications.

The PCB acts as:

- Electrical Pathway – Delivering stable current to each UV LED.

- Mechanical Support – Keeping LEDs securely mounted and aligned.

- Heat Dissipation Platform – Managing excess heat that UV LEDs generate during operation.

Because UV LEDs are sensitive to both heat and current fluctuations, the choice of PCB material and design directly impacts performance, lifespan, and light output efficiency.

Why Choose Copper PCB for UV LED?

A copper PCB for UV LED is considered the premium choice for high-power and long-life UV LED applications. Compared to aluminum or standard FR4, copper offers exceptionally high thermal conductivity—up to 400 W/m·K, nearly twice that of aluminum—and superior electrical conductivity.

Key Advantages:

- Superior Thermal Management

UV LEDs produce more heat per watt than standard LEDs. Excessive heat shortens lifespan, causes wavelength drift, and lowers light efficiency. Copper PCBs transfer heat more efficiently to heat sinks or cooling systems, ensuring LEDs operate within safe temperature ranges.

- Better Electrical Conductivity

Copper’s low electrical resistance means minimal power loss, consistent brightness, and stable performance across all LEDs on the board.

- Higher Current Carrying Capacity

Copper can carry higher currents without overheating, enabling higher-density LED arrays for powerful UV output.

- Durability in Harsh Conditions

UV applications often involve high-intensity light, heat, and sometimes chemical exposure. Copper’s mechanical and chemical stability makes it more reliable than aluminum in such conditions.

- Precision Circuit Etching

Copper allows for finer traces, tighter spacing, and complex multi-layer designs, ideal for compact high-power UV LED modules.

Key Design Considerations for Customized UV LED PCBs

When designing a custom UV LED circuit board, engineers must carefully address several critical factors:

1. Thermal Management Strategy

- Use heavy copper layers (2oz to 6oz) for better heat spreading.

- Integrate thermal vias to move heat from LED pads to the back side for dissipation.

- Use copper-core PCBs or hybrid constructions with metal heat spreaders for extreme cases.

2. Copper Thickness Selection

- Low-power UV LEDs: 1oz copper may be sufficient.

- High-power UV LEDs: 2oz to 6oz copper layers recommended for optimal heat conduction.

3. UV-Resistant Materials

- Use solder masks that resist yellowing, cracking, or degradation from UV exposure.

- Avoid plastics or laminates that break down under UV light.

4. Circuit Layout Optimization

- Even LED spacing for uniform light output.

- Minimized trace length between LEDs to reduce resistive loss.

- Isolated power zones for multi-wavelength UV LEDs.

5. Surface Finish Selection

- ENIG (Electroless Nickel Immersion Gold): Corrosion-resistant and suitable for fine-pitch LED pads.

- Immersion Silver: Excellent conductivity and thermal transfer.

- Avoid finishes prone to oxidation under UV exposure.

6. Heat Sink Integration

- Ensure PCB design matches mechanical interfaces for active or passive cooling solutions.

- For high-output UV modules, forced-air or liquid cooling may be required.

Typical Applications of UV LED Copper PCBs

Due to their durability and heat-handling capabilities, copper PCBs for UV LEDs are used in:

- UV Curing Systems

- Water, Air, and Surface Sterilization

- Medical & Dental Equipment

- Counterfeit Detection & Security

- Photolithography & PCB Fabrication

- Industrial Printing & Coating Systems

Copper PCB vs. Aluminum PCB for UV LED

| Feature | Copper PCB for UV LED | Aluminum PCB for UV LED |

| Thermal Conductivity | ~400 W/m·K | ~200 W/m·K |

| Electrical Conductivity | Excellent (low resistance) | Moderate |

| Current Capacity | High (supports high-power LEDs) | Medium |

| Durability | Excellent (heat & chemical resistance) | Good |

| Cost | Higher | Lower |

| Ideal Use | High-power, high-density, long-lifespan UV | Medium-power, budget-friendly UV |

Summary: If you need maximum efficiency, lifespan, and performance—especially in high-intensity UV applications—copper PCB is the clear winner despite the higher cost.

Why Partner with EBest Circuit (Best Technology) for Your Customized UV LED PCB?

EBest Circuit (Best Technology) has over a decade of expertise in designing and manufacturing custom UV LED circuit boards and copper PCBs for UV LED applications.

Our advantages:

- Custom Engineering Support – From schematic design to thermal simulation.

- High-Capacity Manufacturing – Heavy copper up to 10oz, single- or multi-layer designs.

- Material Expertise – Selection of UV-stable laminates and solder masks.

- Strict Quality Standards – IPC Class 2/3 compliance, 100% electrical and thermal testing.

- Fast Prototyping – Rapid turnaround from design to delivery.

We ensure every PCB is optimized for thermal stability, optical efficiency, and long-term reliability in demanding UV environments. If you want to know more about copper PCB or aluminum PCB, welcome to contact us at sales@bestpcbs.com.

FAQs

Q1: Can copper PCBs handle high-power UV LEDs?

Yes. Copper’s high thermal conductivity ensures heat is quickly removed from LED junctions, preventing overheating and extending lifespan.

Q2: What copper thickness is recommended for UV LED boards?

2oz to 6oz copper is ideal for high-power UV LEDs. Low-power designs may use 1oz copper.

Q3: Is copper PCB always better than aluminum for UV LEDs?

For high-performance, long-life, and high-power applications, copper is superior. Aluminum is acceptable for budget-conscious, medium-power designs.

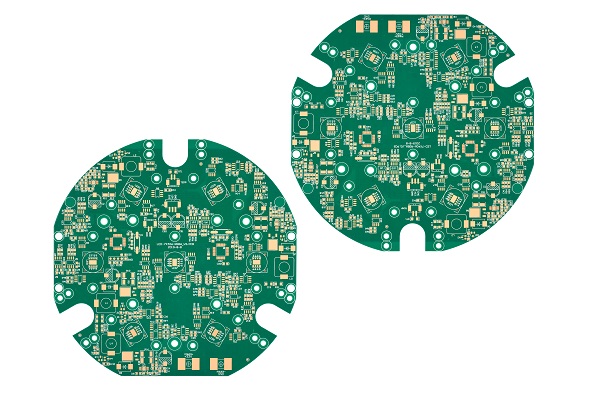

Q4: Can UV LED PCBs be customized in shape and size?

Yes. We offer full customization in dimensions, cutouts, LED arrangements, and connector placements.

Q5: How does UV light affect PCB materials?

Prolonged UV exposure can degrade some solder masks, plastics, and adhesives. We use UV-resistant materials to ensure long-term durability.