Why choose aluminum base PCB for electric vehicle controller? This guide covers definition, technical specs, EV applications, thermal management, cost-reliability balance for aluminum base PCB.

Are you troubled with these issues?

- Traditional PCBs experience thermal degradation under high loads in electric vehicle controllers.

- Vehicle vibrations can cause circuit board connections to fail.

- Improving heat dissipation requires high-cost materials, squeezing profits.

Copper Base PCB can solve these problems:

- Copper has three times the thermal conductivity of aluminum, preventing heat accumulation.

- Copper has twice the tensile strength of aluminum and remains stable in vibration environments.

- Hybrid material design balances heat dissipation and cost.

EBest Circuit (Best Technology) can provide service and solutions:

- Copper substrate with superconducting heat dissipation: Thermal conductivity 398W/m·K (three times that of aluminum), temperature drop ≥50%.

- Vibration-resistant copper substrate: Tensile strength twice that of aluminum, laser micro-hole welding passes 500,000 vibration tests.

- Copper substrate cost-effective solution: Use copper substrate for critical areas and FR4 for non-critical areas, reducing costs by 30% and increasing performance by 200%.

Welcome to contact us if you have any request for aluminum base PCB: sales@bestpcbs.com.

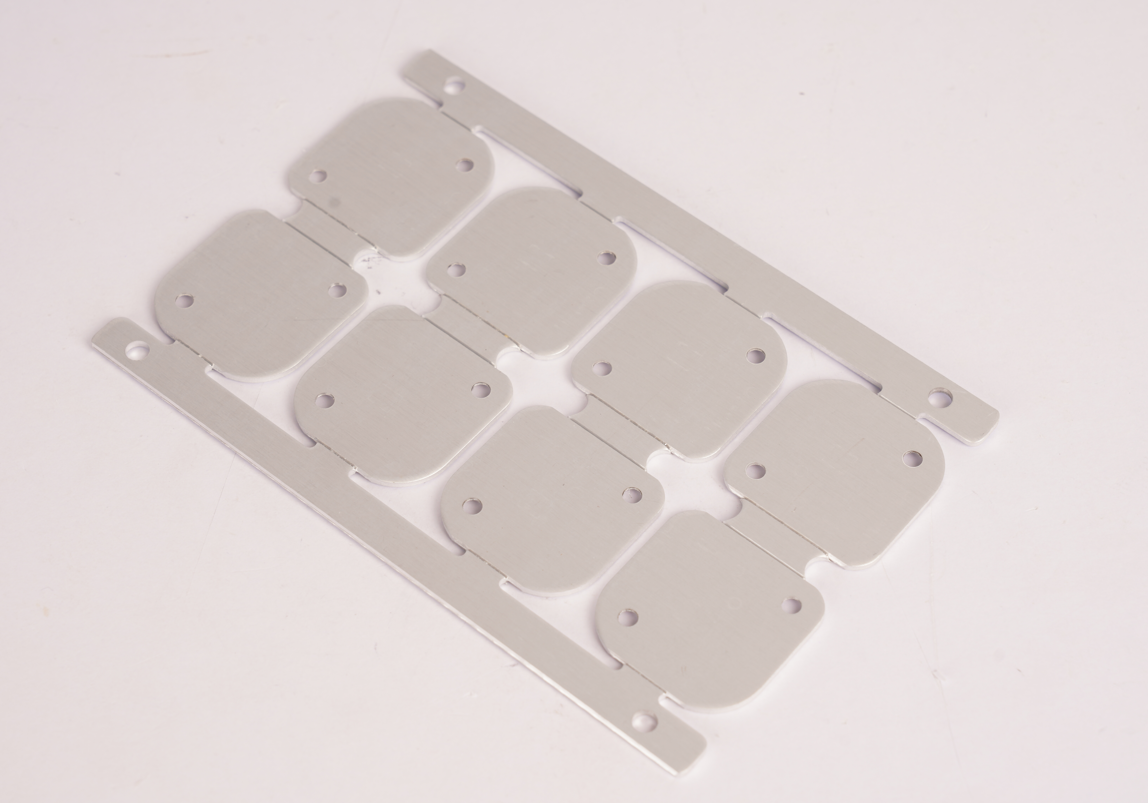

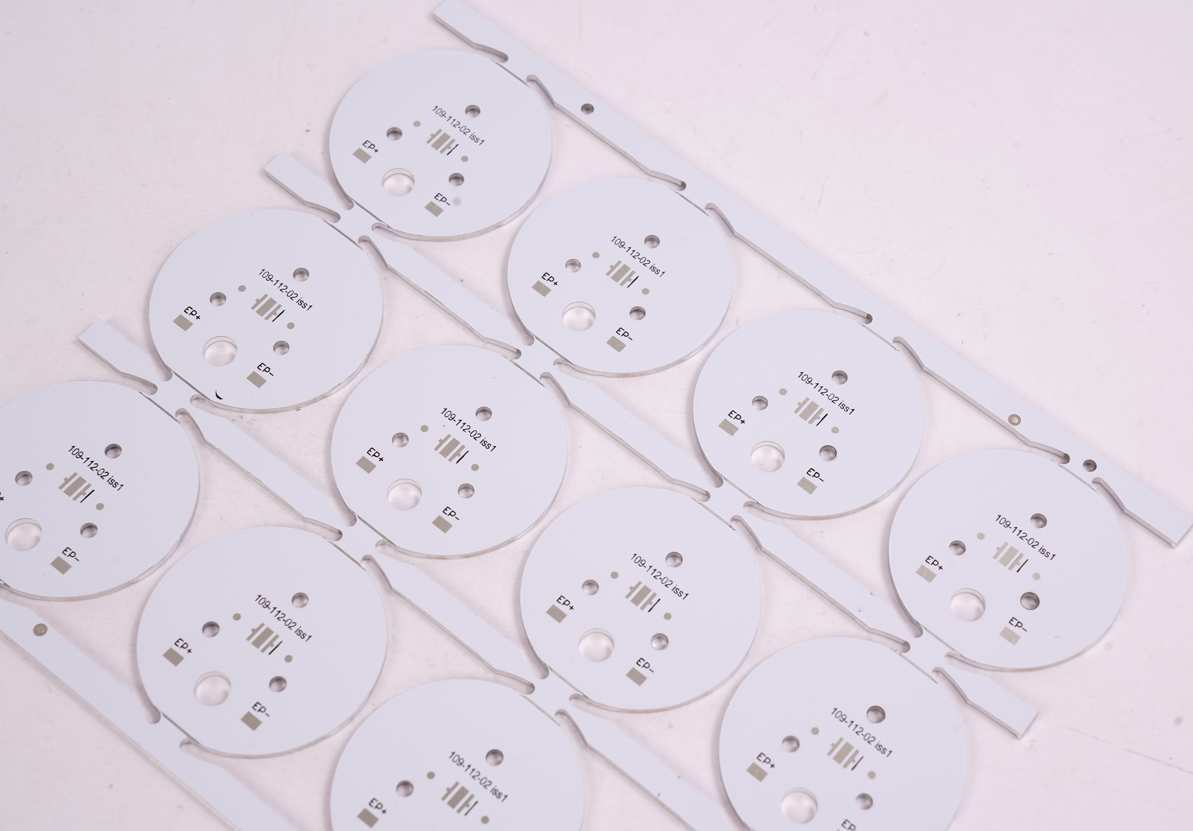

What Is Aluminum Base PCB?

Aluminum Base PCB (also referred to as aluminum substrate PCB) is a circuit board built with an aluminum core substrate, designed for efficient heat dissipation. Its structure includes three layers: an aluminum base layer for thermal management, a dielectric insulating layer, and a copper circuit layer for electrical functionality.

Compared to traditional PCBs, aluminum base PCBs excel in high-power applications (e.g., LED lighting, power supplies) by rapidly transferring heat away from components, reducing overheating risks and extending device lifespan. The aluminum core also enhances mechanical rigidity and dimensional stability, making them durable in harsh environments.

What Are Technical Parameters of Aluminum Substrate PCB?

| Parameter | Specification |

| Base Material | Aluminum (e.g., 5052, 6061) |

| Thickness | 0.8mm–3.2mm (standard: 1.6mm) |

| Copper Foil Thickness | 1oz (35μm) – 3oz (105μm) |

| Dielectric Layer | Epoxy-based or ceramic-filled polymer |

| Thermal Conductivity | 1.0W/m·K – 3.0W/m·K |

| Dielectric Voltage | ≥1.5kV AC (between copper & aluminum layers) |

| Operating Temperature | -40°C – +120°C (continuous) |

| Minimum Line Width/Space | 0.15mm/0.15mm (6mil/6mil) |

| Surface Finish | HASL, ENIG (Ni 3-5μm, Au 0.05-0.1μm) |

| Impedance Control | ±10% (for high-speed signal traces) |

Applications of Aluminum Base PCB in Electric Vehicle (EV) Controllers

- Power Module Thermal Management: Directly mount high-power components (e.g., IGBT, SiC MOSFET) on aluminum base PCBs.

- High-Current Trace Design: Use thick copper layers (2oz–4oz) on aluminum base PCBs to support high-current paths (e.g., battery management, motor drive).

- Mechanical Rigidity & Vibration Resistance: Employ aluminum base PCBs as structural components in EV controllers to withstand mechanical stress, vibrations, and thermal expansion mismatches.

- Compact Layout Optimization: Integrate power electronics, control circuits, and sensors on a single aluminum base PCB.

- Electromagnetic Interference (EMI) Mitigation: Utilize the aluminum layer as a ground plane or EMI shield for high-speed switching components (e.g., inverters).

Why Choose Aluminum Base PCB for Electric Vehicle Controller?

- Superior Heat Dissipation: Thermal conductivity of 1.0-5.0 W/m·K ensures efficient heat transfer from power components (e.g., IGBTs/MOSFETs), reducing thermal throttling and extending controller lifespan.

- Vibration Resistance: High flexural strength (≥150MPa) withstands road-induced vibrations, preventing solder joint failures in harsh automotive environments.

- Compact Design: Eliminates bulky heat sinks, saving up to 30% space in EV controller housings while maintaining thermal performance.

- Cost Efficiency: Combines PCB and heat sink functions, reducing bill-of-materials (BOM) costs compared to traditional FR-4 + heatsink solutions.

- Temperature Resilience: Operates reliably across -55℃~150℃, handling extreme weather conditions and regenerative braking heat spikes.

- Power Density Boost: Enables higher current capacity (1oz copper ≈35A/mm²) for compact high-power motor controllers.

- Reliability Enhancement: Matched CTE (23-50 ppm/°C) minimizes thermal stress on power components during temperature cycling.

- Weight Reduction: Lighter than copper-core alternatives, contributing to overall EV weight savings for improved range.

Aluminum Base PCB Thermal Management Solution for EV Controller

1. Direct Component Mounting on Aluminum Substrate

- Method: Mount high-power devices (e.g., SiC MOSFETs, IGBTs) directly onto the aluminum layer using thermal interface materials (TIMs).

- Implementation: Use aluminum-core PCBs with ≥2.0W/m·K thermal conductivity. Apply low-thermal-resistance TIMs (e.g., silicone-based pads, thermal grease).

- Effect: Reduces thermal resistance by 30–50% compared to traditional FR4 boards.

2. Thick Copper Layer Design for High-Current Paths

- Method: Use 3oz–4oz copper layers for power traces (e.g., battery-to-motor paths).

- Implementation: Widen traces to ≥2mm for currents >50A; Add thermal vias (diameter ≥0.5mm, pitch ≤1.5mm) under high-current areas.

- Effect: Lowers trace temperature rise by 15–20°C under full load.

3. Integrated Aluminum Heat Sink Structure

- Method: Design the aluminum substrate as part of the controller’s heat sink.

- Implementation: Machine the aluminum PCB edge into fins (fin height ≥8mm, thickness ≥1.5mm); Anodize the surface for corrosion resistance.

- Effect: Increases heat dissipation area by 40–60% without additional components.

4. Forced Air Cooling Integration

- Method: Combine aluminum PCB with a low-profile blower fan (airflow ≥50CFM).

- Implementation: Position the fan to direct airflow across high-temperature zones (e.g., MOSFET arrays); Use aluminum PCB fins as secondary heat exchangers.

- Effect: Maintains component temperatures ≤85°C in 40°C ambient environments.

5. Phase Change Material (PCM) Embedment

- Method: Embed PCM (e.g., paraffin-based) within the dielectric layer.

- Implementation: Select PCM with melting point ≤70°C; Use vacuum impregnation to fill PCM into dielectric pores.

- Effect: Absorbs transient heat spikes (e.g., during motor startup), reducing peak temperatures by 10–15°C.

How to Balance Cost and Reliability of EV Controller Aluminum Base PCB?

Measures to Balance Cost and Reliability for EV Controller Aluminum Base PCBs

1. Material Optimization

- Select aluminum substrates with thermal conductivity ≥2.0 W/(m·K) for core heat dissipation areas, while using lower-cost 1.5 W/(m·K) materials in non-critical zones.

- Use 2oz copper foil (instead of 3oz) where current density ≤15A/mm², reducing material costs by 20-30% without compromising conductivity.

2. Design Simplification

- Reduce via density by 30% through optimized routing (e.g., busbar integration), lowering drilling/plating costs.

- Implement hybrid insulation layers: ceramic-filled polymer (high-thermal zone) + standard FR4 (low-thermal zone), cutting dielectric costs by 15%.

3. Process Efficiency

- Adopt laser direct imaging (LDI) for fine-pitch traces (≥50µm), eliminating photoresist film costs and improving yield by 10%.

- Use vacuum lamination for aluminum-dielectric bonding, reducing voids by 50% and avoiding rework.

4. Testing Strategy

- Perform accelerated thermal cycling (ATC) only on critical nodes (e.g., IGBT mounting areas) instead of full-board testing, cutting test time by 40%.

- Validate reliability via computational fluid dynamics (CFD) simulations for heat dissipation, reducing physical prototyping costs by 25%.

5. Supplier Collaboration

- Partner with aluminum substrate manufacturers to customize roll-to-roll production for EV controller dimensions, reducing material waste by 18%.

- Negotiate volume-based pricing for dielectric prepregs, achieving 12% cost savings at ≥5k pcs/order.

6. Standard Compliance

- Design to IPC-6012D Class 3 (automotive) standards upfront, avoiding costly redesigns for certification (e.g., UL, CQC).

- Use AOI (Automated Optical Inspection) for 100% solder joint inspection, reducing field failures by 7% and warranty costs.

7. Lifecycle Cost Analysis

- Trade off initial costs: Spend 15% extra on high-Tg (170°C+) dielectrics to avoid $120k/year in field repairs from thermal degradation.

- Prioritize ENIG surface finish (vs. HASL) for RoHS compliance and SMT reliability, reducing rework labor by 20%.

- Implementation Priority: Material Optimization → Process Efficiency → Supplier Collaboration → Design Simplification.

- Cost-Reliability Ratio: Achieve 25% cost reduction while maintaining >95% reliability (vs. baseline 80% reliability at 30% lower cost).

Why Choose EBest Circuit (Best Technology) as Aluminum Base PCB Manufacturer?

With 19+ years of deep domain expertise, we specialize in high-power projector development, delivering cutting-edge solutions that balance performance, reliability, and cost efficiency. Our advantages include:

- Rigorous Quality Certifications: Compliant with ISO 9001 (quality management), ISO 13485 (medical devices), and IATF 16949 (automotive standards), ensuring global regulatory alignment and product consistency.

- Custom Thermal Management Solutions: Advanced heat dissipation designs extend projector lifespan and enhance reliability, critical for high-brightness applications in demanding environments.

- Competitive Pricing with Transparency: Premium quality at accessible pricing, ideal for cost-sensitive projects without compromising performance.

- 24-Hour Rapid Prototyping: Accelerate time-to-market with ultra-fast prototype delivery, meeting urgent production timelines.

- Free DFM (Design for Manufacturability) Services: Proactive design reviews identify potential issues early, reducing rework costs and development cycles by up to 30%.

- Stringent Quality Control: 100% Automated Optical Inspection (AOI) for mass production orders, ensuring zero defects and long-term operational stability.

- Stable Supply Chain: Strategic material sourcing and inventory management minimize delays, guaranteeing consistent production and on-time delivery.

- Full Turnkey Solutions: End-to-end services from concept design to final delivery, integrating materials, processes, and thermal engineering. Simplify supply chains, mitigate risks, and achieve superior thermal performance.

- 24/7 Global Technical Support: Dedicated engineering team providing real-time troubleshooting and design optimization, minimizing downtime for critical projects.

Welcome to contact us if you have any request for aluminum base PCB: sales@bestpcbs.com.