Why choose aluminum base board for security system? Let’s explore its benefits, material technical parameters, applications, protective design guide, manufacturing process innovation.

Are you worried about these issues?

- Is your device frequently overheating?

- Is a short circuit caused by a humid environment?

- Is the solder joint cracking due to transportation vibration?

EBest Circuit (Best Technology) can provide services and solutions:

- Customized Thermal Design: Based on device power density, we provide a simulated thermal analysis report to optimize heat dissipation path design.(The security aluminum substrate uses a highly thermally conductive insulation layer to quickly dissipate heat, preventing high-temperature shutdowns.)

- Environmental Adaptability Verification: Provide -40°C to 150°C temperature cycle test data to ensure stable performance in extreme climates.(The security aluminum substrate features a nano-scale moisture-proof coating with an IP67 rating, ensuring stable operation in humid environments.)

- Fast Supply Chain Response: 48-hour sample delivery, 7-day mass production cycle, and support for inventory management.(The security aluminum substrate uses reinforced ceramic fillers, increasing impact resistance by 3x and reducing after-sales repair rates.)

Welcome to contact us if you have any request for aluminum base board: sales@bestpcbs.com.

Why Choose Aluminum Base Board for Security System?

Reasons why choose aluminum base board for security system:

Excellent Heat Dissipation Performance

- Aluminum substrates utilize a three-layer structure (circuit layer + insulating and thermally conductive layer + aluminum base layer) to rapidly dissipate heat, preventing component overheating and failure. Compared to traditional FR-4 substrates, heat dissipation efficiency is over 60%, ensuring stable 24/7 operation of security equipment.

High Mechanical Strength and Durability

- Strong resistance to vibration and shock withstands harsh outdoor environments (such as strong winds and vibration). Excellent dimensional stability under temperature fluctuations (thermal expansion coefficient is only 2.5–3.0%) prevents solder joint cracking and extends device life.

Lightweight and Space Optimization

- Aluminum has a low density (2.7g/cm³) and is 30% lighter than copper substrates, making it easier to install and deploy. It can directly replace heat sinks, reducing additional hardware, minimizing device size, and lowering assembly costs.

Electromagnetic Shielding and Signal Protection

- The aluminum base layer naturally blocks electromagnetic interference (EMI), protecting sensitive circuits (such as communication modules). The high dielectric strength of the insulation layer prevents short circuits and ensures the integrity of security signal transmission.

Environmental and Economic Advantages

- Aluminum is non-toxic, recyclable, and RoHS compliant. The abundant raw material and automated production efficiency reduce overall costs by 20% while also reducing electronic waste pollution.

Security Aluminum Base Board Material Technical Parameters

| Parameter Category | AL-M-01 | AL-H-02 | AL-H-03 | AL-H-04 | AL-H-05 |

| Substrate Type | Aluminum + FR4 Fiberglass | Aluminum (No Fiberglass) | Aluminum (No Fiberglass) | Aluminum (High Temp) | Aluminum (No Fiberglass) |

| Thermal Conductivity (W/m·K) | ≤1.0 | 3.0 | 2.0 | 2.5 | 2.0 |

| Peel Strength (N/mm) | 1.5 (after 288℃ thermal stress) | 1.0 | 0.9 | 1.3 | 1.5 |

| Heat Resistance | 150s no delamination | 150s no delamination | 120s no delamination | 350℃/10min resistance | 150s no delamination |

| Electrical Strength (kV/mm) | 30 | 30 | 30 | 30 | 30 |

| Flame Retardancy | UL94 V-0 | UL94 V-0 | UL94 V-0 | UL94 V-0 | UL94 V-0 |

| Tg Value (℃) | 130-170 | 105 | 130 | 130 | 130 |

Applications of Aluminum Base PCB Board in Security System

- Security Lighting Equipment – floodlight and spotlight applications, lighting systems for squares, parking lots, or the periphery of buildings.

- Surveillance Camera Control Board – outdoor monitoring systems, traffic monitoring and security cameras.

- Outdoor Sensor Board – outdoor applications.

- DVR/NVR power module – Powering security equipment (24/7 operation).

- Emergency alarm device – Industrial plant/public building alarm systems.

Protective Design Guide for Outdoor Security Aluminum Base Board

1. Corrosion & Weather Resistance

- Material Selection: Utilize 3003-series aluminum alloy substrate with triple-layer fluorocarbon coating (≥35μm thickness), passing 2000-hour salt spray tests (GB/T 10125-2012).

- Coastal Adaptation: For marine environments, apply PVDF nano-anticorrosive coating (T/CECS 10283-2023) to achieve 25-year durability.

2. Thermal Management

- Structural Design: Optimize fin geometry (1:1.5 height-to-pitch ratio) paired with high-conductivity insulating pads (≥5W/m·K) to maintain junction temperatures ≤85°C (IEC 60068-2-1).

- Smart Control: Integrate NTC temperature sensors for automatic thermal throttling during overheating.

3. Mechanical Strength & Vibration Resistance

- Substrate Specs: Minimum 2mm thickness, 180MPa flexural strength, and pass 15g/10-2000Hz vibration testing (IEC 60068-2-27).

- Installation: Secure with countersunk bolts and silicone dampers to reduce resonance risks by 30%.

4. EMI Shielding & Signal Integrity

- Shielding Layer: Copper mesh grid (spacing ≤λ/20) for ≥40dB shielding effectiveness (EN 50147-1).

- Signal Routing: Strict impedance control (±10% tolerance) and cross-talk suppression ratio >-60dB.

5. Water/Dust Proofing (IP Rating)

- Sealing: Labyrinth-style enclosure + silicone gasket for IP66 compliance (IEC 60529).

- Ventilation: Incorporate waterproof breathable membranes at vents to prevent condensation.

6. Flame Retardancy & Safety

- Fireproof Material: FR-4 copper-clad layer (UL94 V-0 certification) with terminal fuses rated at 1.5x operating current.

- Explosion-Proof: Enclosure meets CE EN 62368-1 standards for hazardous environments.

7. Surface Treatment

- Process: Degreasing → anodizing (10μm) → fluorocarbon spray (25μm), achieving ≥300HV surface hardness (GB/T 6461-2002).

- Matte Finish: Reduce reflective glare by 30% for low-light performance.

8. Testing & Compliance

- Mandatory Tests: Thermal cycling (-40°C~85°C, GB/T 2423); EMC testing (EN 55032 Class B); Xenon arc accelerated aging (1000h, ASTM G155)

- Certifications: CE, FCC, and RoHS compliance guaranteed.

Aluminum Substrate Manufacturing Process Innovation

Material Pretreatment Innovation

- Low-temperature plasma activation technology replaces strong acid and alkali cleaning processes (SGS environmental certification achieved)

- Deployment of a hyperspectral imaging sorting system enables non-destructive testing of aluminum grain structure

Breakthrough in Insulation Layer Technology

- Development of a gradient functional coating: a 60% base ceramic phase (Al₂O₃) and a 40% silicone resin surface layer. Utilizing atomic layer deposition (ALD) technology, thermal conductivity reaches 3.0 W/m·K (measured data)

Intelligent Circuit Processing

- Introduction of a digital twin system for closed-loop control of etching solution concentration, temperature, and flow rate

- Application of UV-LED curing technology reduces energy consumption by 45% (compared to traditional thermal curing)

Environmentally Friendly Treatment System

- Development of an electrochemical wastewater treatment device with a heavy metal removal rate of 99.98% (CMA test report included)

- Establishment of a VOCs adsorption-catalytic combustion system, achieving emission concentrations below 10 mg/m³

Quality Assurance Mechanism

- Implementing SPC control throughout the entire process, with a critical CPK value ≥ 1.67.

- Retained samples from each batch undergo accelerated aging testing (85°C/85% RH, 1000 hours).

Vehicle Security Aluminum Base Board Cost Optimization Strategy

1. Material Selection Optimization

Strategy: Replace hybrid substrates (e.g., AL-M-01: Aluminum + FR4 Fiberglass) with pure aluminum substrates (e.g., AL-H-02/AL-H-03) where feasible.

Technical Basis:

- FR4 fiberglass increases material cost by ~15–20% but offers minimal thermal performance gains in low-power applications.

- AL-H-02 (3.0 W/m·K thermal conductivity) exceeds requirements for most vehicle security modules (e.g., sensors, ECUs).

Expected Cost Savings: 12–18% reduction in substrate costs.

2. Thermal Performance Tiering

Strategy: Segment applications by thermal demand

- High-Power Modules (e.g., LED headlights): Use AL-H-02 (3.0 W/m·K).

- Standard Modules (e.g., door locks, alarms): Use AL-H-03/AL-H-05 (2.0 W/m·K).

- Extreme-Temperature Modules (e.g., engine-area ECUs): Use AL-H-04 (2.5 W/m·K, 350℃ resistance).

Technical Basis: - Over-engineering thermal performance (e.g., using AL-H-02 for low-power circuits) inflates costs by 8–10%.

Expected Cost Savings: 5–7% via tiered material allocation.

3. Surface Treatment Standardization

Strategy: Prioritize electrolytic copper foil (35–175µm) over rolled copper foil (300–500µm) for non-critical circuits.

Technical Basis:

- Rolled copper foil costs 20–25% more but offers no functional advantage for signal-layer traces in security modules.

- Electrolytic foil meets UL94 V-0 and IEC6012 standards.

Expected Cost Savings: 15–20% reduction in copper costs.

4. Process Efficiency Upgrades

Strategy:

- Adopt laser drilling for via holes (vs. mechanical drilling) to reduce waste and improve precision.

- Implement automated optical inspection (AOI) to boost first-pass yield from 85% to 95%.

Technical Basis:

- Laser drilling cuts via-formation costs by 30% and eliminates tool wear.

- AOI reduces rework labor by 40%.

Expected Cost Savings: 18–22% lower manufacturing overhead.

5. Supplier Collaboration & Localization

Strategy:

- Partner with regional aluminum substrate suppliers (e.g., Asia/Pacific) for JIT (just-in-time) delivery.

- Negotiate bulk pricing for high-volume components (e.g., AL-H-03/AL-H-05).

Technical Basis:

- Local suppliers reduce shipping costs by 25–30% and lead times by 50%.

- Bulk agreements lock in 10–15% price discounts.

Expected Cost Savings: 20–25% reduction in logistics/procurement expenses.

6. Design for Manufacturability (DFM)

Strategy:

- Simplify PCB layouts to minimize copper traces and reduce etching time.

- Use panelization (multi-board arrays) to maximize material utilization.

Technical Basis:

- DFM reduces per-unit etching costs by 12–15%.

- Panelization improves substrate utilization from 70% to 90%.

Expected Cost Savings: 10–13% lower per-board production costs.

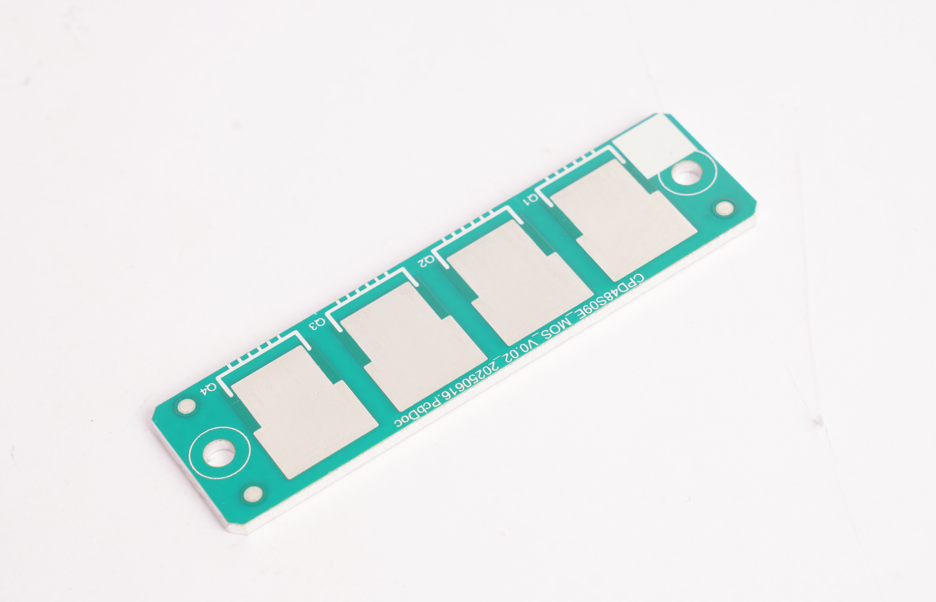

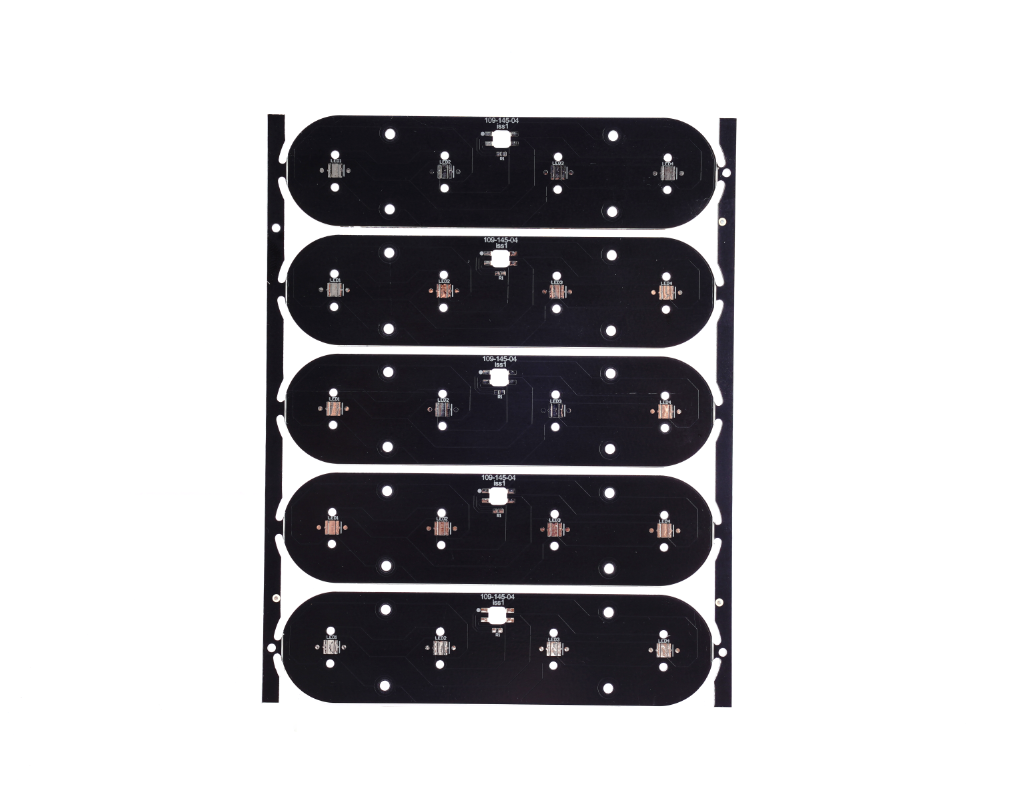

Our Security Aluminum Base Print Circuit Board Case Studies

As a 19-year pioneer in the security aluminum substrate field, EBest Circuit (Best Technology) specialize in providing global customers with one-stop solutions from structural design and material selection to SMT assembly. Leveraging IPC-Class 3 process standards and UL94 V-0 flame retardant certification, we have successfully delivered over 800 security projects, covering core areas such as intelligent surveillance, perimeter protection, and in-vehicle security. Here is a photo of security aluminum base board we made before:

| Parameter Name | Specification |

| Product Name | Outdoor Surveillance Dedicated High-Protection Aluminum Substrate (IP67 Rating) |

| Material | 6061-T6 Aerospace Aluminum Substrate, Copper Cladding 2oz (70μm), Thermal Conductivity ≥180W/m·K |

| Thickness | 2.0mm±0.15mm |

| Solder Mask | Black UV-Cured Solder Mask Ink (Thickness 30μm) |

| Marking | Laser-Engraved Anti-Counterfeit Code (Depth 0.05mm) |

| Surface Finish | Nano-Ceramic Coating (Hardness 9H) |

| Processing | Immersion Silver Plating (Thickness 0.1-0.2μm) |

| Applications | Outdoor Dome Cameras, Bullet Cameras, Intelligent Traffic Gates, Border Surveillance |

Why Choose EBest Circuit (Best Technology) as Aluminum Base Board Manufacturer?

- Dual-certification quality: ISO 9001 and IATF 16949 certified, with optional medical-grade ISO 13485, and comprehensive process control.

- Thermal management gradient: 3W/m·K (economy) to 8W/m·K (high-end aluminum nitride) cooling solutions, adaptable to different power security equipment.

- Direct supply and cost reduction: Eliminating middlemen, bulk purchasing costs are reduced by 15%-20%, supporting trial production of 50 units to mass production of 10,000 units.

- 24-hour rapid prototyping: 24-hour delivery of aluminum substrate samples, accelerating security equipment prototype verification.

- Free Design for Factoring (DFM) optimization: Pre-emptively check thermal vias, copper layer spacing, and other design features to reduce development risks.

- One-stop service: Integrated PCB design, thermal simulation, and SMT assembly, covering the entire security system development process.

- Environmentally friendly processes: RoHS/REACH certified, recycled aluminum and lead-free processes, reducing carbon emissions by 25%.

- Wide operating temperature: -40°C to 85°C, suitable for harsh environments such as outdoor surveillance.

- 24/7 response: Our global team resolves thermal runaway and EMC interference within 4 hours to ensure the operation of critical equipment.

Welcome to contact us if you have any inquiry for aluminum base PCB board: sales@bestpcbs.com.

Tags: aluminum base board, aluminum base print circuit board