PCB contract manufacturing plays a key role in todayâs electronics industry, especially during prototyping. It bridges the gap between design and actual production, helping teams launch new hardware faster and with fewer mistakes. If you’re struggling with design flaws, delays, or inconsistent quality, youâre not alone. Many companies face the same issuesâand thatâs where a reliable PCB partner becomes a game-changer.

At EBest Circuit (Best Technology), our prospects and regular customers get superb quality PCB contract manufacturing from Prototypes to PCBA. Providing superb quality, high mix, fast delivery, and no MOQ turnkey PCB assembly to an increasingly competitive market is our market positioning. You can enjoy our technical capability for customizing a variety of PCBs, such as single-sided PCBs, multilayer PCBs, HDI PCBs, extra-thin PCBs, high-speed PCBs, and so on. If you have any inquiries regarding PCB fabrication services or PCBA contract manufacturing, just shoot us an email at sales@bestpcbs.com.

What is PCB Contracting?

PCB contracting refers to a collaborative business model where a company outsources the production and assembly of printed circuit boards to a professional third-party under a contractual framework. It typically encompasses both PCB contract manufacturingâfocused on fabrication and assembly executionâand engineering collaboration, such as DFM (Design for Manufacturability) optimization and material selection consulting. While the terms are often used interchangeably, PCB contracting emphasizes the strategic partnership aspect, whereas contract manufacturing focuses on process delivery.

In a typical setup, the client submits finalized design filesâlike Gerber, BOM, and ODB++âand the contractor takes over fabrication, component sourcing, assembly (including SMT, through-hole, or hybrid), functional testing, and even certification compliance (such as RoHS, REACH, or UL).

This model is increasingly adopted across high-demand sectors such as automotive electronics, aerospace systems, 5G communication infrastructure, AI computing platforms, and industrial automation. The reason is simple: it reduces internal overhead, enhances speed-to-market, and provides immediate access to advanced capabilities without investing in in-house facilities.

With the right PCB contract partner, companies benefit from much more than just manufacturingâthey gain co-engineering insight, proactive design validation, and a scalable supply chain that accelerates product launch while minimizing risk.

Does PCB Assembler Provide Services from Prototype to PCBA?

Yes. A capable PCB assembler usually provides support from prototyping to full PCBA. EBest Circuit (Best Technology), for example, offers design reviews, prototyping, component sourcing, fabrication, PCBA, and testing, streamlining every step. Our early collaboration tools and strict DFM reduce common prototype failures like thermal blind spots and impedance errors.

What Does PCB Fabrication Services Include?

PCB fabrication services cover everything needed to produce bare boards. This includes material selection, layer stack-up planning, copper etching, drilling vias, solder mask application, and surface finishing. Quality fabricators like EBest Circuit (Best Technology) go further by offering impedance control, zero-void microvias, and warpage control to avoid delamination and BGA defects in prototypes.

How to Ensure Quality During PCBA Contract Manufacturing?

Ensuring quality during PCBA contract manufacturing requires a combination of advanced inspection tools, robust process control, and traceable component sourcing. At EBest Circuit (Best Technology), we integrate a multi-stage quality management protocol aligned with industry best practices:

- Incoming Inspection

Our quality process begins at the gate. In addition to XRF spectroscopy for verifying metal content in surface finishes (such as ENIG or immersion silver), we conduct visual inspections, dimensional checks, and dielectric resistance validation on laminate materials. This ensures compliance with IPC-4101 and IPC-6012 standards before production even starts. - In-Process Control

During SMT and through-hole assembly, we utilize 3D AOI (Automated Optical Inspection) paired with cutting-edge defect recognition software. While our internal defect detection rate is over 99.7%, we still apply manual review stations at critical checkpoints. This hybrid approach helps catch subtle issues such as tombstoning, skewed components, and incomplete solder joints, which automated systems alone may miss. - Final Testing & Validation

Before delivery, every board undergoes comprehensive testing based on its design class. These include:- TDR (Time Domain Reflectometry): For impedance validation in high-speed circuits.

- Thermal Shock Testing: Simulates environmental stress across -40°C to +125°C cycles.

- ICT (In-Circuit Test): Detects shorts, opens, and passive value deviations.

- FCT (Functional Circuit Test): Verifies logic performance and power integrity under load.

- Component Integrity & Traceability

To counter component substitutionâespecially during global shortagesâwe implement a dual-layer approach:- Vendor Qualification: We source only from authorized distributors with RoHS/REACH-compliant declarations.

- Blockchain-Linked BOM Tracking: A secure digital ledger ties each part to its supplier, batch number, and inspection record. This safeguards against counterfeit components and ensures end-to-end traceability.

Our closed-loop SPC (Statistical Process Control) system continuously monitors process deviations and initiates AI-driven corrections in real-time. Through this ecosystem, weâve reduced prototype-related defects by up to 78%, helping customers meet tight timelines without sacrificing reliability.

Is Turnkey PCB Assembly Difficult?

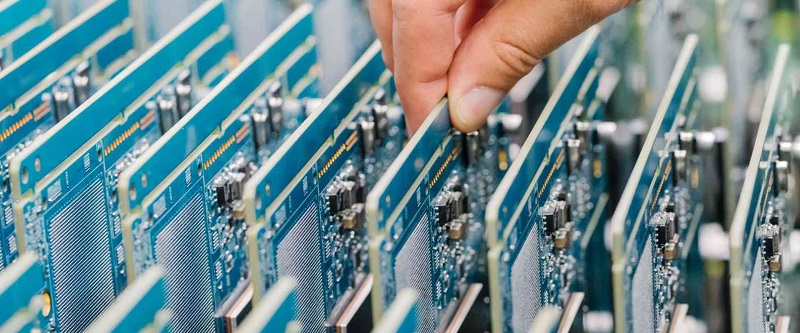

Not with the right partner. Turnkey PCB assembly means the contractor handles fabrication, sourcing, assembly, and testing. It may sound complex, but EBest Circuit (Best Technology) simplifies it using integrated systems. Their Component Bank Network provides common stocked items, reducing sourcing delays. We also use a three-shift production model for faster deliveryâmost prototypes ship in 5 days.

Why Might a Company Choose PCB Contract Manufacturing?

There are many reasons companies prefer contract manufacturing:

- Cost Efficiency: Avoids large capital investment in manufacturing facilities.

- Speed: Speeds up prototype iterations and reduces launch delays.

- Expertise: Gains access to experienced engineers and technicians.

- Risk Reduction: Minimizes design-induced and process-based errors.

Ultimately, outsourcing enables companies to focus on design innovation while specialists like EBest Circuit (Best Technology) take care of the rest.

Why Choose EBest Circuit (Best Technology) for PCB Contract Manufacturing?

EBest Circuit (Best Technology) goes far beyond just assembling boards. Our strengths are rooted in solving the most common and costly customer needs during prototyping. Hereâs how they lead the market:

- Design-Manufacturability Support: Our advanced DFM tools and early collaboration portal catch thermal gaps, impedance issues, and unclear markings before production.

- Advanced Manufacturing: From 20-layer HDI with tight impedance control to surface prep, we support even complex builds.

- High-mix PCB lines: Our PCB portfolio includes FR4, semi rigid-flex PCB, FPC, MCPCB, ceramic PCB. All PCBs support the full service from PCB prototypes to SMT PCBA.

- End-to-End Traceability: MES integration gives full transparency and trust.

- Speed: With 3-shift lines and additive hybrid processes, lead times drop by up to 85%.

- Certifications: AS9100D, ISO 13485, and IATF 16949 ensure compliance across critical sectors.

Prototyping is not just about quick buildsâitâs about building it right the first time. PCB contract manufacturing can either simplify or complicate your workflow depending on the partner you choose. EBest Circuit (Best Technology) helps eliminate 78% of common prototype issues by combining engineering collaboration, certified manufacturing, and lightning-fast production. From 1-layer boards to aerospace-grade 20-layer stacks, weâre more than just a supplierâweâre a co-engineering partner. If you have any questions or need any help, please contact us via email at sales@bestpcbs.com.