Aluminium clad PCBÂ is widely chosen for applications that demand high thermal performance, durability, and stable operation under tough conditions. Whether you’re designing LED lighting systems or power converters, aluminium PCBs can offer better heat dissipation and mechanical support compared to traditional boards.

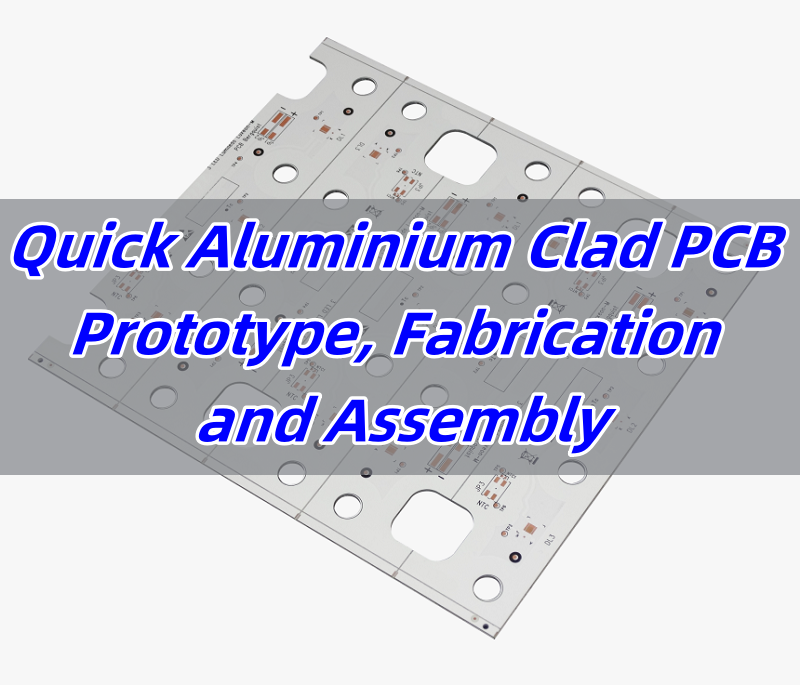

EBest Circuit (Best Technology) is the primary custom MCPCB manufacturer in China, providing quick aluminium clad PCB prototype, fabrication, and assembly services in a very large market. We have our factory conforming with ISO 9001, ISO 13485, IATF 16949, AS9100D, UL, REACH, and RoHS. We have a competitive edge in quality control through improved manufacturing processes as well as through sophisticated inspection equipment. It would be nice if you could share your request for new enquiries with our team at sales@bestpcbs.com, then we could share the quote specifically.

What is Aluminium Clad PCB?

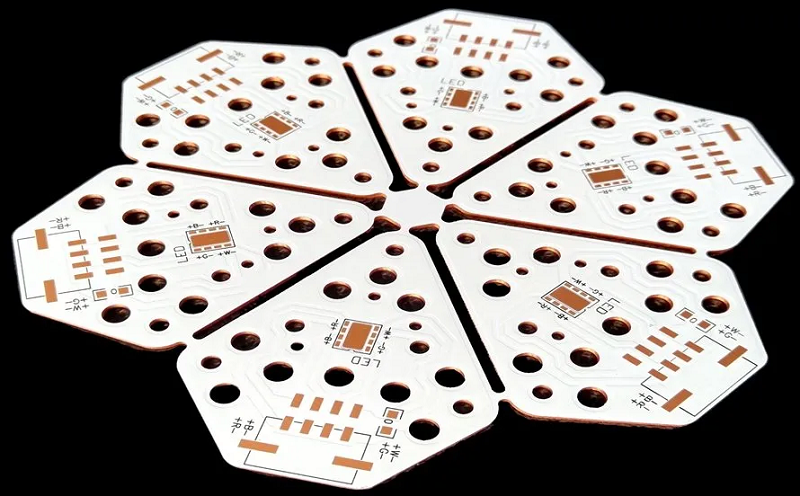

An aluminium clad PCB consists of a thin layer of thermally conductive dielectric material, laminated between a copper circuit layer and an aluminium base. This structure helps conduct heat away from critical components. It’s often used in high-power applications where heat control is essential.

What is the Difference: Aluminum PCB vs FR4?

FR4 is a standard fiberglass material used in many PCBs. In contrast, aluminium clad boards use metal for the base, offering superior heat conduction. Aluminium boards are more robust, but FR4 is flexible for complex layer designs. Choosing between them depends on your projectâs thermal needs and mechanical demands.

What is Aluminium Clad PCB Price?

Aluminium clad PCB price depends on board size, copper thickness, aluminum grade, and complexity. Although it may cost more than FR4 in raw material, it saves costs in heat sinks and boosts durability. For cost-effective prototypes and small runs, EBest Circuit (Best Technology) offers competitive pricing and fast delivery.

What are Metal Clad PCB Specifications?

Key specifications of metal clad PCBs can vary depending on the application, but the typical ranges include:

- Base Material: Commonly used aluminium alloys are 5052 and 6061, both offering good strength and thermal properties. While 3003 can be used, it is less typical due to its lower mechanical strength and thermal conductivity.

- Thermal Conductivity: Standard aluminium clad PCBs offer thermal conductivity between 1.0 to 2.0 W/mK. Higher values, such as 3.0 W/mK, are available but usually require special high thermal conductivity materials, which may increase cost.

- Copper Thickness: The copper layer usually ranges from 1oz to 6oz. The 1oz to 3oz range is most common, but higher thickness is possible for heavy current applications.

- Board Thickness: Standard thickness ranges from 0.8mm to 3.2mm, but thinner boards, such as 0.6mm, can also be manufactured based on project needs.

- Surface Finish: Typical surface treatments include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative). The choice depends on the specific assembly process and performance requirements.

These specifications allow metal clad PCBs to deliver efficient heat management and maintain structural integrity under demanding conditions. However, values should be tailored to suit the productâs real-world operating environment for best results.

What is Delamination on an Aluminum Clad PCB?

Delamination refers to the separation between layers. On aluminium boards, it can happen due to poor lamination or thermal stress. Using high-quality bonding materials and strict process control helps avoid this issue. EBest Circuit (Best Technology) uses advanced lamination techniques and thermal cycling tests to ensure reliability.

What is the Purpose of Clad Aluminum?

Clad aluminum serves two key purposes: mechanical strength and heat management. It acts as a heat sink, drawing heat away from components. It also adds rigidity, which is helpful in high-stress environments such as automotive and industrial controls.

What are the Advantages of Aluminum PCB Material?

Aluminium PCB material offers several benefits:

- Excellent thermal conductivity

- Improved durability and support

- Reduced need for additional heat sinks

- Cost-effective in high-power applications

- Lightweight yet strong structure

These advantages make aluminium PCB board ideal for LED lighting, power electronics, and automotive sectors.

What is Aluminium PCB Board Used For?

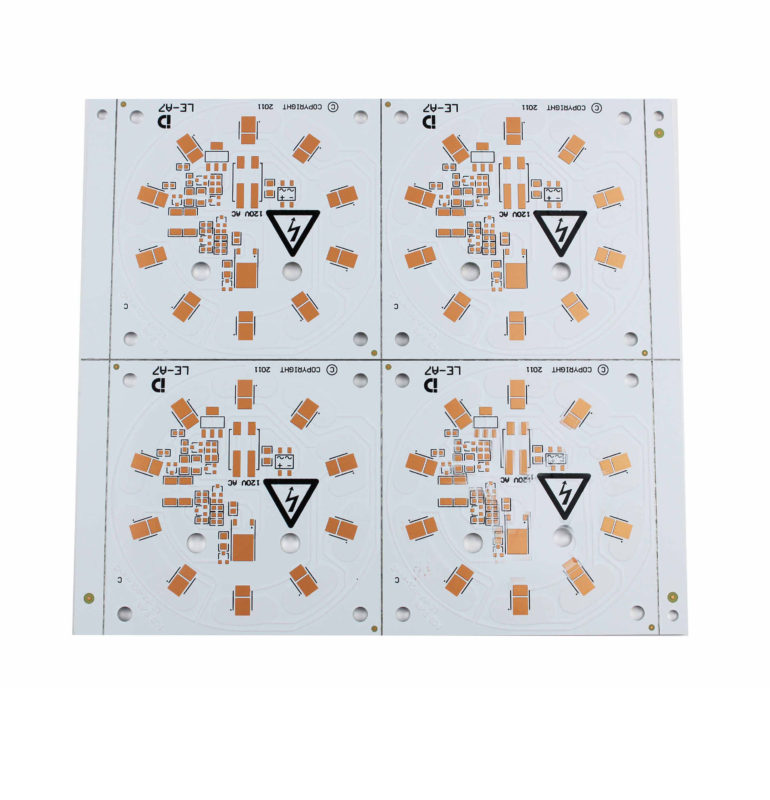

Common uses include:

- LED lighting systems

- Power supplies and inverters

- Automotive lighting and control systems

- Solar panels and power modules

The aluminium PCB board for LED is especially popular due to its ability to manage high heat from LED chips efficiently.

How to Ensure Quality During Aluminium PCB Manufacturing Process?

Quality control is key. Steps include:

- Material inspection â Ensure consistent aluminium quality

- Precise drilling and etching â Maintain tight tolerances

- Thermal testing â Validate heat transfer capabilities

- Visual inspection â Check for delamination or cracks

EBest Circuit (Best Technology) uses MES systems for full traceability. Our in-process monitoring ensures every board meets strict quality standards, reducing defects and customer returns.

Why Choose EBest Circuit (Best Technology) for Aluminium PCB Board for LED?

Customers often face issues like delayed delivery, unstable quality, or poor communication from suppliers. At EBest Circuit (Best Technology), we address these problems with clear solutions:

- Fast Prototyping: Quick turn services to meet tight deadlines

- Stable Quality: Certified by ISO9001, ISO13485, and IATF16949

- 24/7 Technical Support:Â English-speaking engineers and responsive support

- Customization:Â Flexible for small or large volume, special designs welcomed

We offer aluminum PCB enclosures, full assembly, box build, and testing services to simplify your project workflow. With over 1700 satisfied global clients, weâve built a reputation for on-time delivery and reliable product performance.

In closing, choosing the right partner for your aluminium clad PCB needs can make or break your project timeline and budget. EBest Circuit (Best Technology) offers a complete solution â from prototype to final assembly. We understand your need for speed, quality, and clear communication. With rigorous quality control and stable manufacturing process, we help reduce risks and support your success. If you have enquiries concerning aluminium clad PCB, just let us know at sales@bestpcbs.com or +86-755-2909-1601. We will try our best to meet your requirements. Any enquiry made always gets our response quickly.

Tags: Aluminium Clad PCB