Copper IMS PCBÂ costs can climb fast, especially in high-power or LED projects. Yet, you donât have to accept high pricing. This blog will walk you through practical ways to cut your copper IMS PCB costs by 25%, without losing quality.

EBest Circuit (Best Technology) is a leading IMS PCB manufacturer, delivering Copper IMS PCB and aluminum IMS PCB prototypes, fabrication, assembly, and box build service to the increasingly developing world of electronics. Most of our engineers have worked at EBest Circuit (Best Technology) for over 10 years. We can apply our empirical knowledge to do DFM reviews and recommend the most suitable material that meets your performance target.

Moreover, supporting low to medium volume orders and short lead times gives us a competitive edge in world markets. Per our company policy, there are normally 2-3 weeks for the complex boards, and we will adhere to this policy from the top down without any excuses. This saves you the headache of the MOQ barrier and unpredictable and long times. Whatever questions or enquiries you have about copper IMS PCB will be answered by our team, pls do call at +86-755-2909-1601 or sales@bestpcbs.com.

What is a Copper IMS PCB?

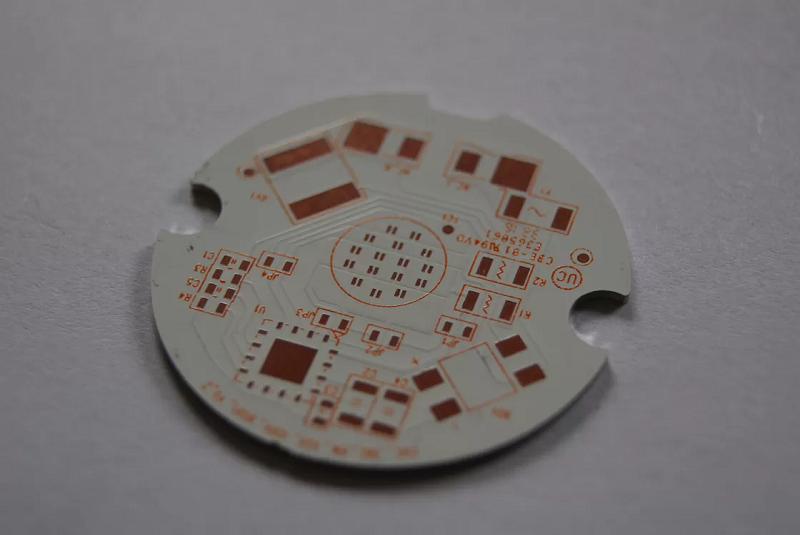

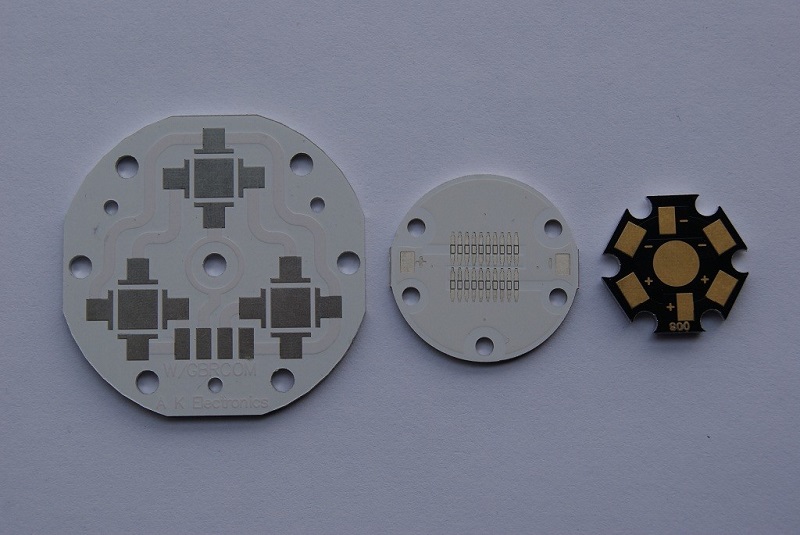

A copper IMS PCB stands for insulated metal substrate circuit board with a copper base. Unlike aluminum IMS boards, copper offers better thermal conductivity. These boards are used in power electronics, LED lighting, and automotive systems where heat control matters most.

What Are Other Names for Copper IMS PCB?

Besides copper IMS PCB, people call them copper core PCBs, copper metal core boards, or copper-based IMS boards. Sometimes, they are referred to as thermal copper PCBs due to their role in heat dissipation.

Are IMS Printed Circuit Boards Made of Copper?

Not all IMS printed circuit boards use copper. Many are made with aluminum. However, when thermal demand is high, copper is preferred for its superior conductivity and durability. So, copper IMS PCB is often used in demanding environments.

What Is the Difference: Copper IMS PCB vs Copper MCPCB?

Many people think copper IMS PCB and copper MCPCB are the sameâbut they are not exactly equal. Letâs break it down.

Key Differences:

| Feature | Copper IMS PCB | Copper MCPCB |

|---|---|---|

| Meaning | Copper board with insulation layer | Copper board, may or may not have insulation |

| Structure | 3 layers: Circuit + Insulation + Copper Base | May have only Copper Base and Circuit |

| Focus | Highlights heat control + insulation | Highlights metal core |

| Usage | High voltage, high power (e.g., LED, power) | General applications, lower insulation need |

| Relationship | A type of MCPCB with insulation | Broader group, includes IMS boards |

Simple Summary:

- Copper IMS PCB = special copper MCPCB that must have an insulation layer.

- Copper MCPCB = copper metal board, not always insulated.

- So, every copper IMS PCB is a copper MCPCB, but not every copper MCPCB is an IMS PCB.

This difference matters when your project needs both heat control and electrical insulationâthen, go for copper IMS PCB.

What Temperature to Solder Copper IMS?

Copper IMS PCBs have great heat-spreading ability, but careful control during soldering is still necessaryâmainly to protect the insulation layer. Here are the key points to know:

- Typical Temperature Range

Soldering temperatures usually fall between 220°C and 280°C. This matches well with most lead-free solders, which melt at around 217°C to 250°C. However, always check the exact type of solder you’re using and adjust the temperature accordingly. - Insulation Layer Protection

While copper spreads heat fast, the insulation layer (often made from polyimide or similar materials) can only handle 200°C to 250°C for short periods. If the temperature is too high or held too long, the insulation may delaminate or even carbonize, leading to long-term failure. - Peak Temperature Control

Keep the peak soldering temperature no more than 30°C to 40°C above the solderâs melting point. For example, if your solder melts at 240°C, aim for 270°C to 280°C. This range helps prevent damage while ensuring proper solder flow. - Soldering Time

Limit the soldering time to 2â4 seconds at peak temperature. But itâs not just about timeâalso manage your temperature curve, including preheating and cooling. A smooth curve helps reduce thermal stress on the insulation. - Testing Is Essential

Before starting mass production, run tests. Methods like TGA (Thermogravimetric Analysis) or DSC (Differential Scanning Calorimetry) help confirm how well the insulation layer handles heat. These tests can catch weak points early.

To conclude, copper IMS PCBs need careful soldering, even though they manage heat well. Protect the insulation layer by controlling temperature and time, and always validate your process before full production. This ensures long-term reliability without hidden risks.

What Is a Copper Pour in IMS Printed Circuit Board?

In copper IMS PCBs, a copper pour is a large area of copper applied across parts of the board. It plays a key role in heat spreading and grounding, but thereâs more to understand. Hereâs what matters:

- Types of Copper Pour

There are two common types:

- Solid Pour â a fully filled copper area, ideal for thermal management.

- Grid Pour â a mesh-like pattern, mainly used to reduce EMI (electromagnetic interference) but less effective for heat.

In IMS PCBs, solid copper pour is preferred because it transfers heat better.

- How It Works

The copper pour connects to the copper base through thermal vias or directly, depending on design. It reduces thermal resistance, helping heat flow from hot components into the copper base. The insulation layer, typically with 1â3 W/m·K thermal conductivity, also aids this process. - Benefits for Current Flow

Besides heat, copper pour can improve current flow by reducing resistance pathsâespecially useful in high-power circuits. - Cost Saving Potential

By designing a smart copper pour, you may reduce or even avoid extra heat sinks. But this depends on your component layout and power density. If components are spread out, the pour helps spread heat more evenly. - EMI Consideration

Copper pour also affects electromagnetic interference. A well-designed pour can shield signals and lower EMI, but poor design might cause noise issues. So, it’s important to balance thermal and electrical needs.

In a nutshell, copper pour in IMS PCBs is more than just extra copper. Itâs a tool for better thermal control, grounding, and possibly cost reduction. Using solid pour for heat and careful layout helps you get the most out of your copper IMS PCB design.

What Are the Price Differences: Copper IMS PCB vs PCB?

Copper IMS PCB is more expensive than standard FR4 PCB. The reasons include the cost of copper, complex fabrication, and thicker insulation layers. Yet, when you compare performance, especially in thermal control, copper IMS PCB often justifies its price. In the long run, it prevents failures and reduces rework costs.

What Is the Primary Role of Copper in PCB?

Copper in PCB handles both signal transmission and heat transfer. In copper IMS PCBs, copper mainly moves heat away from components. This prevents overheating and boosts lifespan. It also ensures power flows efficiently across the board.

How to Cut Copper IMS PCB Costs?

Hereâs how you can save up to 25% without losing quality:

1. Optimize Board Design

Efficient layouts cut material waste. Using the right copper thickness and pour design can save money and improve heat flow. Avoid over-designing areas where itâs not needed.

2. Use Standard Panel Sizes

Non-standard sizes increase costs. By designing copper IMS PCB that fits common panel sizes, you save on material and labor.

3. Choose the Right Manufacturer

A reliable IMS PCB manufacturer offers better pricing with quality. EBest Circuit (Best Technology) offers cost-effective solutions thanks to its streamlined process and MES tracking. This prevents delays and errors, saving your time and money.

4. Order in Bulk

Higher volumes reduce unit cost. Plan your orders to maximize economies of scale.

5. Avoid Excessive Tolerances

Unneeded tight tolerances add cost. Confirm which tolerances are essential for function, and where you can relax specs.

6. Select the Right Finish

Some finishes cost more than others. Choose one that meets your needs without overpaying. HASL or ENIG may be enough for most copper IMS PCBs.

7. Plan Ahead for Assembly

Working closely with your assembler ensures smoother processes. Avoid late changes which can drive up rework costs. Early design for manufacturing reviews helps prevent this.

Why Choose EBest Circuit (Best Technology) as Your Original IMS PCB Manufacturer in China?

EBest Circuit (Best Technology) solves key customer problems in copper IMS PCB production.

- 24/7 Technical Customer Service: Many buyers face delays, inconsistent quality, or unclear communication. Our team ensures prompt support and fast feedback within 12 hours.

- Premium Qualityâ IMS Board PCB: We utilize the ISO9001, IATF16949, and AS9100D systems to ensure total quality control.

- Cutting-edge Material Management System: Our MES (Manufacturing Execution System) ensures complete traceability of components, preventing any mix-ups. Clients trust us for consistent quality, even in complex builds.

- NO MOQ: We support both small and large volume orders with fast turnaround. Whether you need copper IMS PCBs for LED lighting or automotive, we deliver without MOQ. Our technical team works with you from start to finish, offering effective solutions instead of just the boards.

In short, EBest Circuit (Best Technology) doesnât just make copper IMS PCBsâwe help you succeed in your projects with the right solutions, on time and budget.

All in all, cutting copper IMS PCB costs doesnât mean cutting corners. By focusing on smart design, choosing standard panel sizes, and partnering with the right manufacturer, you can reduce costs by up to 25%âwithout sacrificing quality or reliability. However, many buyers struggle with slow responses, poor quality control, and unclear communication. These issues not only delay projects but also lead to higher costs in the long run.

At EBest Circuit (Best Technology), we help you avoid these problems. Our professional team offers quick feedback, strict quality control, and full traceability through MES systems. We support both small and large volume orders, and weâre committed to delivering consistent, high-quality copper IMS PCBs on time. If you have new projects for enquiry, pls let us know your specific requirement at sales@bestpcbs.com, then we can quote you as rapid as we can.

Tags: Copper IMS PCB