Aluminum circuit boardĀ is your first choice for prototypes needing efficient heat dissipation and mechanical strength. In today’s fast-moving electronic world, having a reliable board partner speeds up development and lowers risks. Letās go through the types, benefits, manufacturing, and moreāso you can make better decisions.

As a well-known aluminum circuit manufacturer, EBest Circuit (Best Technology) supports decent quality aluminum circuit boards for prototypes. Our factory presents a wide variety of MCPCBs, like copper core PCB, single-layer MCPCB, COB MCPCB, double-sided MCPCB, multilayer MCPCB, and SinkPAD board. All our aluminum circuit goes through the most stringent electrical circuit test, AOI, and visual inspection. Our aluminum printed circuit boards are commonly used in aerospace, automotive, medical industries, LED lighting, and industrial equipment. It would be very nice of you to share the Gerber Files you have via email at mcsales@bestpcbs.com, then we will be glad to share the quote with you as quick as we can.

What Is Aluminum Circuit Board?

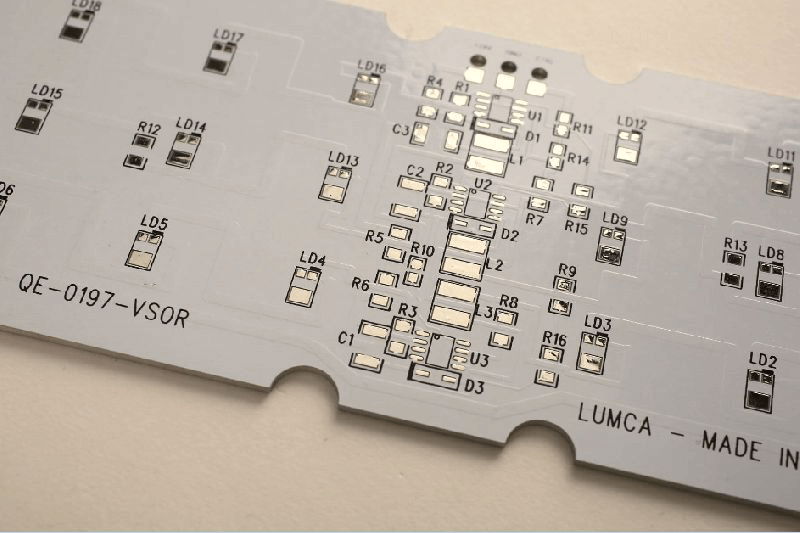

An aluminum circuit board, also called metal core PCB or MCPCB, uses aluminum as its base instead of traditional FR4. It improves heat management and structural durability, which is vital for LED lighting and power devices. Unlike regular boards, these handle high temperatures without deforming. Thatās why many engineers choose aluminum PCBs during prototyping.

What Is the Type of Aluminium PCB Board for LED?

For LED projects, the most common type is single-sided aluminum PCB. Itās compact and handles thermal loads well. But in high-power or RGB LED systems, double-sided or multilayer aluminum PCBs offer better performance. They reduce LED failure by improving heat flow. EBest Circuit (Best Technology) supports custom layouts, even in tight spaces or dense LED arrangements.

Which Is Better: Aluminum PCB vs FR4?

Which is better: aluminum PCB vs FR4? Aluminum PCB beats FR4 in thermal performance. It draws heat away from sensitive parts, boosting LED lifespan and reducing risk. While FR4 costs less, it canāt manage heat well, especially in power circuits. In prototypes with high-current designs or compact layouts, aluminum wins. Plus, it supports better mechanical strength, cutting down failures during handling.

How Is the Aluminium PCB Manufacturing Process?

Making aluminum circuit boards involves steps like copper etching, dielectric lamination, and mechanical drilling. The copper layer must be etched with tight control. Some suppliers struggle hereāespecially above 3oz copper thickness. But EBest Circuit (Best Technology) applies auto optical width checks and dynamic compensation algorithms. That keeps the line width deviation under Ā±0.02mm, even with 8oz copper. For heat bonding, vacuum lamination and real-time monitoring improve consistency, reducing delamination risks in LED arrays.

How Is the Aluminum Circuit Board Price?

Aluminum circuit board price varies with size, copper weight, layer count, and surface finish. Basic single-layer aluminum PCBs are cost-effective. But high-current designs with multiple layers cost more. Still, when you compare the longer LED lifespan, saved redesigns, and lower cooling costs, they provide better long-term value. EBest Circuit (Best Technology) offers reasonable aluminum PCB prices, especially for small batches and prototypes.

What Are the Advantages of Aluminum Printed Circuit Boards?

They shine in thermal management. The metal core pulls heat away quickly, protecting components. They’re durable and resist cracking better than FR4. For LED lighting, aluminum PCBs keep junction temperatures in the safe zone. This extends light quality and life. They also reduce the need for heat sinks, cutting system cost and weight. Aluminum PCB boards are also RoHS compliant and recyclable, supporting green goals.

Why Choose EBest Circuit (Best Technology) as One of Your Reliable Aluminum Circuit Board Manufacturers?

EBest Circuit (Best Technology) handles the technical challenges of aluminum PCB prototyping with skill. Letās explore how we solve key demands.

1. Reliable Thermal Bonding

In LED arrays, poor bonding causes delamination and shortens lifespan. We use vacuum lamination and thermal imaging to detect flaws early. Thermal conductivity adhesives ensure better heat paths, with interface resistance as low as 0.8 K/W.

2. Complex Layout Support

Some designs need tight layouts. We support 0.5oz – 10oz conductor thickness, 4/4mil line space, and 0.48mil PTH wall thickness for HDI. The max board dimension supports up to 610*1625mm, and the MCPCB layers support up to 10 layers. Our thermal mapping and 3D layout tools balance heat and layout densityāgreat for power-dense applications.

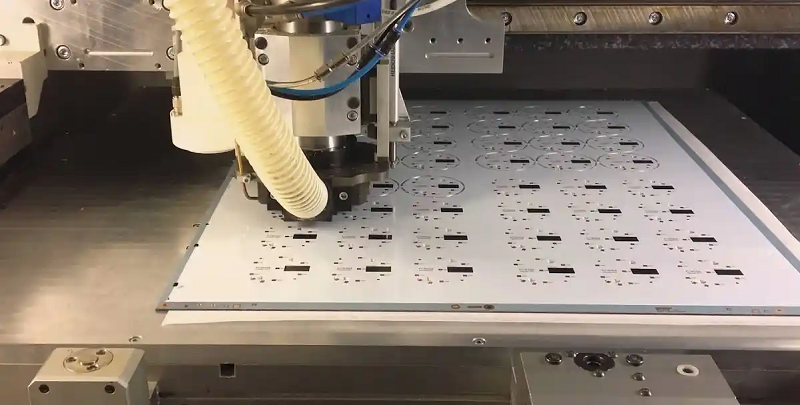

3. Controlled Drilling & Milling

CNC defects slow down prototyping. With laser depth control and anti-vibration tools, we prevent burrs and hole deformation. That means more reliable testing and less rework.

4. Strict Quality Assurance

We follow ISO 9001, ISO 13485, IATF 16949, AS9100D, and IPC Class 3. All batches are traceable, RoHS-safe, and meet UL requirements. Heat cycle tests from -55Ā°C to +150Ā°C, AOI checks, and electrical tests ensure long-term reliability.

5. Turnkey EMS MCPCB Manufacturing Service

EBest Circuit (Best Technology) provides turnkey service from material procurement, MCPCB design, DFM analysis, MCPCB prototype, mass production, MCPCB assembly.

6. A Variety of Different MCPCBs

There are different varieties of our MCPCB portfolio, such as aluminum core PCBs, copper core PCBs, and Insulated Metal Substrate (IMS) PCBs with thermal vias. All support different layers, and there is no MOQ requirement for all our product lines.

In a nutshell, choosing a decent quality aluminum circuit board for your prototype is about more than just materials. Itās about solving thermal, layout, and manufacturing issues from the start. At EBest Circuit (Best Technology), we combine tech with process precision to overcome copper etching limits, bonding risks, and dense design hurdles. With our smart systems and certified quality, we support fast and successful prototyping for LED, power, and compact electronics. Feel free toĀ emailĀ usĀ at sales@bestpcbs.com or call us at +86-755-2909-1601, if you have any questions or would like to get more information.

Tags: aluminum circuit board