Want to get a homemade PCB? Explore its benefits, application, limitations, making process and why choose EBest Circuit (Best Technology) as a PCB partner.

What Is A Homemade PCB?

A homemade PCB is a printed circuit board created using DIY methods, often for prototyping or small-scale projects. Unlike professionally manufactured PCBs, which involve advanced processes and materials, homemade PCBs are made using simpler techniques such as etching, milling, or toner transfer. These methods are cost-effective and accessible for hobbyists and small-scale projects, though they may not match the precision and durability of professionally manufactured PCBs.

What Are the Advantages of Homemade PCB?

Advantages of homemade PCB:

- Cost-Effective: Affordable materials and tools for small-scale projects.

- Accessibility: Easy to create with basic equipment and materials.

- Customization: Flexibility to design and modify PCBs as needed.

- Learning Opportunity: Great for understanding PCB design and manufacturing processes.

- Additional Advantages of Homemade PCBs.

- Rapid Prototypingā: Enables immediate design adjustments and functional testing, bypassing commercial fabrication delays.

- Enhanced Process Controlā: Direct oversight of etching, drilling, and soldering parameters ensures tailored quality for niche applications.

- Reduced Lead Timesā: Eliminates reliance on external vendors, accelerating project timelines for urgent iterations.

- Experimental Adaptabilityā: Supports unconventional designs (e.g., mixed-signal layouts or hybrid materials) for research-specific needs.

- Skill-Driven Optimizationā: Enables manual refinement of trace geometries and impedance matching, critical for high-frequency circuits.

Applications of Homemade PCB Board

Applications of homemade PCB board:

- Prototyping: Testing and refining circuit designs before mass production.

- Hobby Projects: Creating small-scale electronics for personal use (e.g., LED controllers, audio amps).

- Education: Learning PCB design, soldering, and electronics fundamentals.

- Custom Electronics: Building unique or one-off devices (e.g., retro gaming consoles, smart home sensors).

- DIY Gadgets: Crafting specialized tools (e.g., 3D printer controllers, robotics modules).

- Repair and Modification: Fixing or upgrading existing circuits with tailored solutions.

- Art Installations: Designing interactive light displays or kinetic sculptures.

- IoT Devices: Developing low-cost connected sensors or smart home accessories.

- Robotics: Prototyping motor drivers, sensor interfaces, or control boards.

- Research and Development: Experimenting with novel circuit topologies or materials.

- Gift Making: Personalizing electronics (e.g., custom-engraved LED name tags).

- Environmental Monitoring: Building weather stations or pollution sensors for field use.

What are the Limitations of Homemade PCB board?

Limitations of homemade PCB board:

- Precision: Lower accuracy compared to professionally manufactured PCBs.

- Durability: Less robust and prone to wear and tear.

- Complexity: Limited to simpler designs and fewer layers.

- Time-Consuming: Requires more time and effort to produce.

- Material Limitationsā: Inability to utilize advanced substrates (e.g., high-frequency laminates) or precision finishes critical for specialized applications.

- Fault Detection Challengesā: Lack of professional testing equipment complicates troubleshooting of hidden defects like micro-shorts.

- Scalability Issuesā: Manual processes hinder consistent reproduction for medium-to-large production batches.

How to Make a Homemade PCB?

Below are process of how to make a homemade PCB:

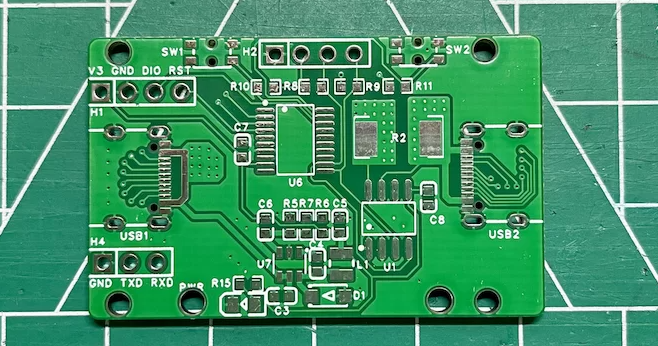

1. Design the PCB Layout

- UseĀ EDA softwareĀ (e.g., Autodesk Eagle, KiCad, or EasyEDA) to design your circuit schematic and PCB layout.

- Ensure proper component placement, signal routing, and adherence to design rules (e.g., trace width, spacing).

- Export the design as aĀ Gerber fileĀ or printable format (e.g., PDF/PNG).

2. Prepare Materials and Tools

Materials:

- Copper-clad laminate (FR-4 recommended).

- Laser printer, glossy paper, or transparent film.

- Ferric chloride (FeClā) or ammonium persulfate (etching solution).

- Drill bit (0.5ā1 mm for through-hole components).

- Sandpaper, gloves, and safety goggles.

Tools:

- Iron or laminator (for toner transfer).

- Drill press or hand drill.

- Plastic container for etching.

3. Print the PCB Layout

- Print the PCB layout as aĀ mirror imageĀ on glossy paper using a laser printer.

- Ensure high contrast and no broken traces.

4. Prepare the Copper-Clad Board

- Cut the copper-clad board to size using a hacksaw or PCB cutter.

- Clean the copper surface with sandpaper to remove oxidation.

5. Transfer the Layout to the Board

- Toner Transfer Method:

- Place the printed glossy paper (ink-side down) on the copper board.

- Iron the paper at medium heat for 5ā10 minutes.

- Soak the board in water to loosen the paper, then gently rub off the paper to reveal the toner pattern.

- Alternative: Use a UV exposure system with photoresist-coated boards for higher precision.

6. Etch the Board

- Submerge the board in ferric chloride solution (1 part FeClā to 2 parts water).

- Agitate gently for 15ā30 minutes until excess copper is dissolved.

- Rinse thoroughly with water and remove the toner with acetone.

7. Drill Holes

- Use a drill press or hand drill to create holes for components.

- Reference the Gerber file for precise hole locations.

8. Apply Solder Mask and Silkscreen (Optional)

- Paint the board with liquid solder mask or use a UV-curable mask for protection.

- Add component labels using a silkscreen pen or laser printer toner transfer.

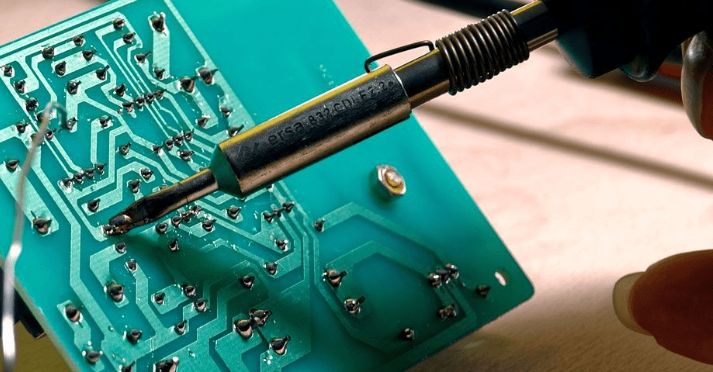

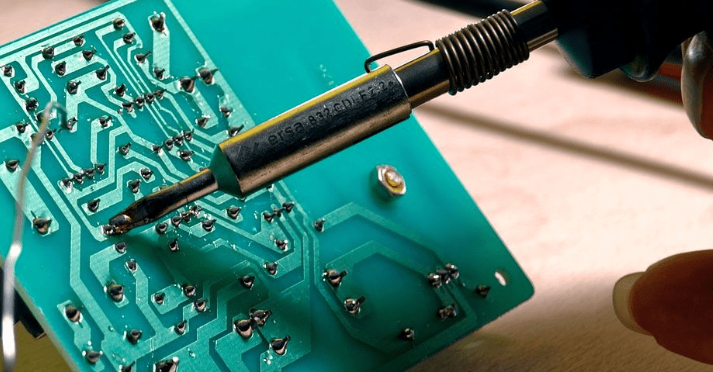

9. Finish and Test

- Clean the board with isopropyl alcohol.

- Apply a thin layer of solder flux and tin the traces if needed.

- Assemble components and test for continuity/shorts using a multimeter.

10. Safety Precautions

- Wear gloves and work in a well-ventilated area when handling chemicals.

- Dispose of etching solution responsibly (check local regulations).

Why Choose Professional PCB Manufacturing?

While homemade PCBs are great for small projects, professional PCB manufacturing offers:

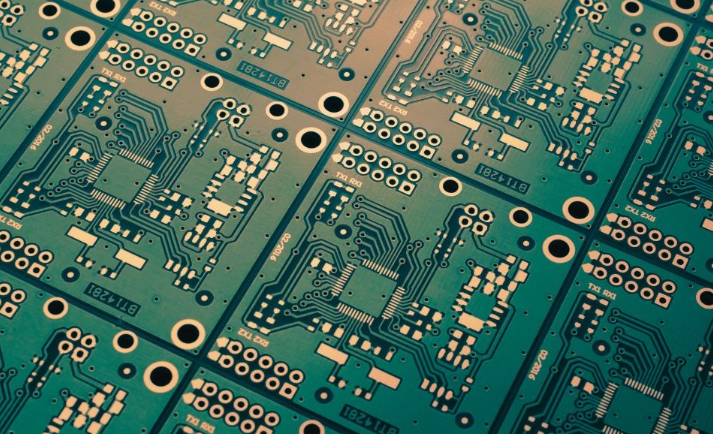

- High Precision: Advanced processes for accurate and reliable PCBs.

- Durability: Robust materials and finishes for long-lasting performance.

- Complex Designs: Support for multi-layer and high-density designs.

- Scalability: Efficient production for large-scale projects.

Our Professional PCB Services

At EBest Circuit (Best Technology), we offer comprehensive PCB manufacturing services, including:

- Custom Design: Tailored solutions to meet your specific requirements.

- Material Selection: High-quality materials for optimal performance.

- Precision Manufacturing: Advanced processes for accurate and reliable production.

- Quality Assurance: Rigorous testing to ensure reliability and performance.

Why Choose Us for Your PCB Needs?

EBest Circuit (Best Technology) stands out as a trusted partner for homemade PCB manufacturing, offering tailored solutions to meet your unique needs. Hereās why we are the ideal choice:

Lightning-Fast Lead Times & 24-Hour Rapid Prototyping

- 24-hour sample delivery: Receive your PCB prototypes within 24 hours of approval, accelerating your product development cycle.

- Urgent order support: Expedited production for time-sensitive projects, ensuring you never miss a deadline.

Customized Sample Production with No MOQ

- Minimum order quantity (MOQ) = 1 piece: Perfect for prototypes, small-batch hobby projects, or niche custom designs.

- Flexible customization: Tailor specifications (e.g., layer count, trace width, materials) to match your exact requirements.

Free DFM Analysis to Optimize Costs

- Design for Manufacturability (DFM) checks: Our engineers analyze your design for potential issues (e.g., trace spacing, via placement) atĀ no cost, preventing costly revisions later.

- Cost-saving recommendations: Identify opportunities to reduce material waste and streamline production without compromising quality.

Pre-Sales & After-Sales Support

- Multilingual team: Instant assistance via chat, email, or phone in English, Chinese, and other languages.

- Technical expertise: Engineers provide real-time guidance on design, material selection, and troubleshooting.

Guaranteed Post-Sales Support

- Quality assurance: Rigorous testing (e.g., electrical tests, AOI inspections) ensures defect-free boards.

- Hassle-free returns/replacements: Quick resolution for any issues, backed by our commitment to customer satisfaction.

- Long-term partnership: Ongoing support for revisions, scaling, or future projects.

Contact Us Today

Whether you need homemade PCBs for prototyping or professional PCBs for large-scale production, EBest Circuit (Best Technology) is here to help. Contact us today to discuss your PCB needs and get a quote: sales@bestpcbs.com.

Tags: Homemade PCB, Homemade PCB Board