Discover everything about 2-layer PCB, including their advantages, applications, manufacturing process, and why EBest Circuit (Best Technology) is the ideal partner for your PCB needs.

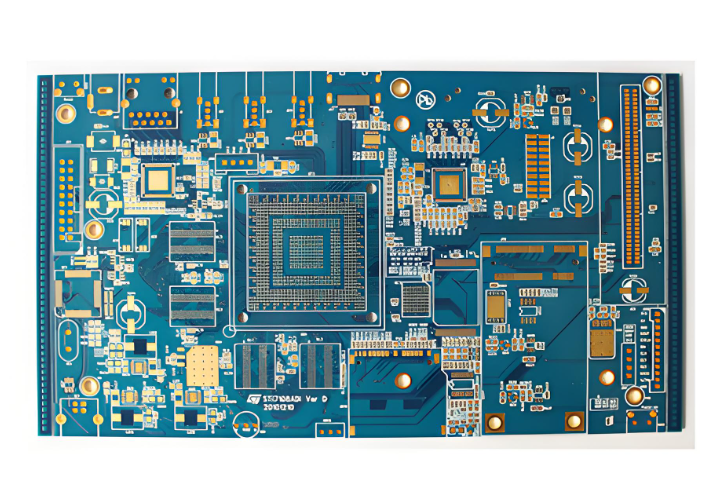

What is a 2-Layer PCB?

A 2-Layer PCB, also known as a double-layer PCB, is a printed circuit board that consists of two conductive copper layers. These layers are located on the top and bottom surfaces of the board, separated by an insulating substrate material. 2-Layer PCBs are widely used in electronic devices due to their ability to support more complex circuits than single-layer PCBs while remaining cost-effective and relatively simple to manufacture.

2-Layer PCB

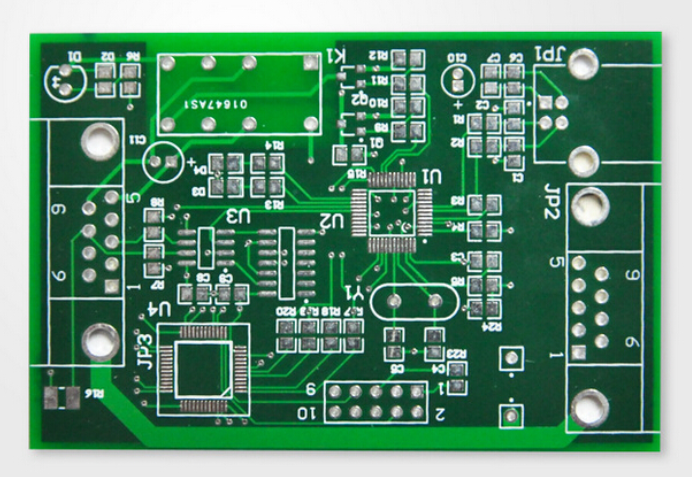

What are the Advantages of 2-Layer PCB?

- Increased Circuit Complexity: Allows for more intricate designs by utilizing both sides of the board.

- Cost-Effective: Balances functionality and affordability, making it ideal for many applications.

- Compact Design: Enables space-efficient layouts, perfect for devices with limited space.

- Improved Signal Integrity: Reduces electromagnetic interference (EMI) and enhances performance.

- Versatility: Suitable for a wide range of industries, from consumer electronics to industrial equipment.

What are the Advantages of 2-Layer PCBs?

What Problems Can 2-Layer PCBs Solve?

2-Layer PCB address several challenges in electronic design and manufacturing:

- Space Constraints: Compact designs for devices with limited space.

- Circuit Complexity: Supports more complex circuits without the cost of multi-layer PCBs.

- Signal Interference: Minimizes EMI and crosstalk for better performance.

Applications of 2-Layer PCBs

2-Layer PCB are used in various industries and applications, including:

- Consumer Electronics: Smartphones, tablets, and home appliances.

- Industrial Equipment: Control systems and automation devices.

- Automotive Electronics: Sensors, control units, and infotainment systems.

- Medical Devices: Diagnostic equipment and monitoring systems.

- Telecommunications: Routers, modems, and communication devices.

Our Services for 2-Layer PCBs

At EBest Circuit (Best Technology), we offer comprehensive services for 2-Layer PCB, including:

- 2-Layer PCB Design: Customized design solutions tailored to your needs.

- 2-Layer PCB Prototyping: Fast and accurate prototyping to validate your design.

- 2-Layer PCB Manufacturing: High-quality production adhering to industry standards.

- 2-Layer PCB Assembly: Full assembly services, including SMT and thru-hole components.

Why Choose Us for 2-Layer PCBs?

- 18+ Years of Experience: Proven expertise in delivering high-quality PCBs.

- Competitive Pricing: Affordable solutions without compromising quality.

- Quick Turnaround: Expedited services with 24-hour shipping for urgent orders.

- ISO-Certified Quality: Adherence to IPC standards, including Class 2, Class 3, and Class 3A.

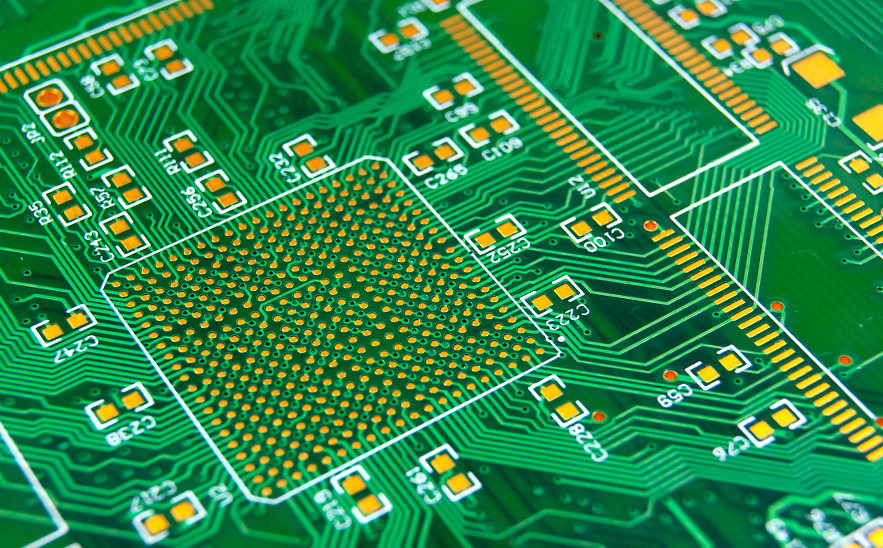

2-Layer PCB Manufacturing Capabilities

| Parameter | Capability |

|---|---|

| Layers | 2 |

| Material | FR4, Aluminum, Ceramic, etc. |

| Board Thickness | 0.4mm – 3.2mm |

| Copper Thickness | 0.5oz – 6oz |

| Minimum Trace/Space | 3mil/3mil |

| Surface Finish | HASL, ENIG, OSP, etc. |

| Solder Mask | Green, Blue, Red, etc. |

| Silkscreen | White, Black, etc. |

How is a 2-Layer PCB Different from Other PCBs?

- Single-Layer PCBs: Only one conductive layer, limiting circuit complexity.

- Multi-Layer PCBs: Three or more layers, offering higher complexity but at a higher cost.

- 2-Layer PCBs: Two conductive layers, balancing complexity and cost-effectiveness.

If you have any questions about 2-Layer PCBs or would like to request a quote, feel free to contact us. We are committed to providing the best quality, pricing, and services to meet your PCB needs.