How do I choose copper busbar? Let’s explore material, application, function, , difference between tin plated copper bus bar, selection guide and lifespan for copper busbar.

Are you troubled with these issues?

- Is your busbar overheating and shutting down?

- Is poor-quality copper causing resistance spikes?

- Are supplier delivery delays disrupting your production schedule?

EBest Circuit (Best Technology) can provide service and solution:

- High-Conductivity, Low-Loss Busbar Customization: Made with 99.99% electrolytic copper, achieving 8% lower energy loss.

- Flexible Production Service: Supports custom thickness cutting (5mm-50mm), with daily production capacity exceeding 300 tons.

- Intelligent Selection Support: Free current-carrying/temperature rise simulation reports provided to precisely match project requirements.

Welcome to contact us if you have any request for copper busbar: sales@bestpcbs.com.

What is Copper Busbar?

A Copper Busbar is a thick conductive strip integrated into a printed circuit board, typically made of highly conductive materials such as copper or aluminum, specifically designed for efficient power distribution and carrying high currents. Its core design breaks away from the traditional PCB reliance on etching copper traces, instead directly achieving circuit connections by embedding thick copper or aluminum strips (up to millimeter-level thickness), significantly enhancing current carrying capacity and conductivity efficiency.

Copper Busbar Material Specification

| Parameter | Specification |

| Material | Pure copper (>99.90% Cu) (Soft Copper) |

| Oxygen Content | ≤80ppm (Standard Cu) / ≤10ppm (High-purity Copper) |

| Surface Treatment | Tin/Chrome/Hot-dip Galvanized (Tin-plated) |

| Dimensional Range | Width:15-400mm |

| Thickness:1-80mm | |

| Length:100-1000mm (Chrome-plated) | |

| Mechanical Properties | Tensile Strength:200-250MPa |

| Elongation:15-45% | |

| Hardness:HB≥65 (Galvanized) | |

| Electrical Conductivity | >56m/s (Room Temperature) (Standard Cu) |

How Do I Select Copper Busbar?

Here’s a selection guide about copper busbar:

1. Define Current Requirements

- Calculate the maximum system current and select a busbar with sufficient cross-sectional area (current density for copper busbars typically ≤4A/mm²).

- Formula: Cross-sectional area (mm²) = Current (A) / Current density (A/mm²).

2. Select Material Type

- Pure copper: Prioritize T1/T2 electrolytic copper (Cu ≥99.9%) for high-conductivity scenarios (e.g., precision instruments).

- Copper alloy: Choose copper-chromium (high-temperature resistance), copper-zirconium (creep resistance), or copper-nickel (corrosion resistance) based on needs.

3. Consider Environmental Adaptability

- Humid/corrosive environments: Prioritize for tin-plated (anti-oxidation) or nickel-plated (acid/alkali resistance) busbars.

- High-temperature scenarios: Select silver-plated (softening temperature up to 300°C) or copper-chromium alloy.

- Radiation/nuclear environments: Use radiation-resistant materials (e.g., special coatings).

4. Verify Mechanical Connection

- Check if screw holes, slots, or custom designs are needed to ensure compatibility with devices (e.g., PCBs, switchgear).

- Prioritize pre-drilled or customizable busbars for simplified installation.

5. Assess Thermal Needs

- For high-current applications, choose thick copper busbars (leveraging copper’s high thermal conductivity).

- For compact devices, opt for copper-aluminum composite busbars (35% lighter, similar thermal performance to pure copper).

6. Match Installation Space

- Measure available space in the device and select busbars with appropriate dimensions (length, width, thickness) to avoid layout conflicts.

7. Validate Standards & Certifications

- Ensure busbars comply with international standards (e.g., IEC 60228, UL 758) for safety and reliability.

8. Balance Cost & Performance

- For general use, select T2/T3 copper busbars (cost-effective). For demanding scenarios, prioritize alloy or plated busbars (performance-first).

- Choose suppliers with ISO 9001 quality certificates to ensure consistent quality. (Like EBest Circuit (Best Technology))

What is a Busbar Copper Used for?

- Power Distribution: Connects generators, transformers, switchgear, and other equipment to form main circuits, enabling efficient power transmission and distribution.

- Mechanical Connection: Acts as a rigid conductor with screw holes/slots to directly secure components, simplifying assembly.

- High Current Carrying Capacity: Suitable for industrial power supplies, electric furnaces, rail transit, and other scenarios requiring 100s to 1,000s of amperes (A).

- Thermal Management: Leverages copper’s high thermal conductivity to assist heat dissipation in devices like inverters and LED lighting, enhancing system stability.

- Special Environment Adaptation: Corrosion-resistant coatings like nickel-plated for chemical or coastal facilities; radiation-resistant materials for nuclear equipment.

- Compact Design: Replaces traditional cables to reduce wiring space, ideal for high-density devices such as data centers and photovoltaic (PV) inverters.

- Composite Function Integration: Copper-aluminum composite structures reduce weight for new energy vehicle battery connections.

When to Use Busbar Copper?

Power Systems

- Main wiring of substations (connecting transformers & HV switchgear).

- UPS distribution in data centers.

- LV switchgear internal connections for industrial plants.

Renewable Energy

- PV array convergence (connecting modules & inverters).

- Wind turbine tower cable replacement.

- Inter-module connections in battery energy storage systems.

Rail Transportation

- DC busbar systems for metro traction substations.

- High-speed train rooftop HV equipment interconnection.

- Railway signaling power distribution networks.

Industrial Equipment

- Motor Control Center (MCC) main incoming lines.

- Power transmission for electric arc/medium frequency furnaces.

- Power distribution units in automated production lines.

Building Infrastructure

- Vertical busway power supply for commercial complexes.

- Backup power circuits for hospital operating rooms.

- Hybrid lighting/power systems in airport terminals.

Special Environments

- Radiation-resistant power distribution in nuclear containment buildings.

- Marine propulsion systems for high-salinity environments.

- Explosion-proof electrical installations in chemical plants.

Tin Plated Copper Bus Bar vs Copper Bus Bar

| Characteristic | Tin-Plated Copper | Bare Copper |

| Corrosion Resistance | Excellent (especially marine/humid environments) | Standard (requires protective coatings) |

| Electrical Conductivity | Comparable to pure copper (98% IACS) | 100% IACS Conductivity |

| Applications | Marine equipment, appliance grounding, switchboard neutral lines | General industrial power distribution |

| Cost | Higher (approx. ¥8,200/ton) | Lower |

| Weldability | Easier to weld (standard soldering) | Requires professional welding techniques (brazing/welding) |

| Typical Dimensions | Common 300×40×5mm, etc. | Wider size range available (thickness 1-80mm) |

What Is the Life Expectancy of a Copper Busbar?

Copper busbars typically exhibit a service life of 20–50 years, contingent upon material quality, operating environment, and load conditions. Premium pure copper or alloyed busbars maintain long-term stability in dry, low-corrosion environments. Conversely, exposure to humid/corrosive atmospheres or persistent overcurrent loads may degrade performance due to oxidation, creep deformation, or thermal stress. Implementing protective coatings ( such as silver plating) or strength-enhanced alloys ( such as CuCr or CuZr) significantly extends longevity. Under standard industrial maintenance, decades of reliable operation are consistently achievable.

Why Choose EBest Circuit (Best Technology) as Copper Busbar PCB Supplier?

Reasons why choose us as copper busbar PCB supplier:

- Certified Reliability: Full certifications (ISO/UL/IPC/RoHS/REACH) ensure global compliance, reducing clients’ regulatory risks by 40%.

- High-Current Performance: 20A/mm² current density (33% higher than industry average) cuts copper usage by 30%, saving space/material costs.

- Strict Quality Inspection: 99.7% defect detection rate + 12-parameter testing minimizes post-installation failures (<0.3%).

- Free DFM Support: Avoid design errors in advance and reduce production costs by 15%.

- 24 Hours Rapid Prototyping: accelerate project kickoff by 50%, enabling faster market entry.

- Turnkey Solution: Providing one-stop service from copper busbar design to assembly, saving customers time and production costs.

- Transparent Pricing: 12% cost advantage via optimized copper utilization, with all-inclusive quotes (no hidden fees).

- Long-Term Durability: Uniform copper plating (≤15% thickness variation) enables 20+ years of reliable operation in extreme temperatures.

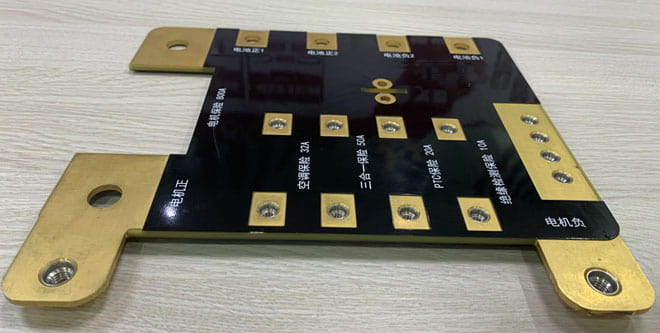

Here is a photo of copper busbar PCB we made before:

Welcome to contact us if you have any inquiry for copper busbar PCB: sales@bestpcbs.com.