Europe’s PCB prototyping space serves automotive, aerospace and medical sectors with uncompromising precision and reliability. PCB prototype Europe services excel in strict quality compliance and technical proficiency for low-volume, complex projects. EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) is a partner with Europe PCB manufacturer, It specializes in PCB prototype service Europe and one-stop assembly, fully complying with regional standards. Global supply chain shifts drive demand for nearshore PCB prototype Europe production to cut lead times and boost stability.

Top 10 PCB Manufacturer in Europe for Prototyping List

| Company Name | Main Business | Core Advantages | Process Capability | Lead Time |

| EBest Circuit Co., Limited (Best Technology Circuit Co., Limited) | PCB prototyping, PCBA assembly, HDI PCB production | 19-year experience, global certification, MES system tracing | 2-32 layers, ceramic PCB, HDI, impedance control | 24hrs urgent, 3-7 working days for standard |

| AT&S (Austria) | High-tech PCBs, IC substrates for automotive/aerospace | Strong R&D, global presence, strict quality control | Multilayer HDI, high-frequency PCBs, IC substrates | 7-14 working days for prototypes |

| Schweizer Electronic (Germany) | Custom PCBs, embedded solutions for industrial/medical | Family-owned expertise, innovative technologies, customer-centric | Rigid-flex, heavy copper, high-temperature materials | 5-10 working days |

| Eurocircuits (Germany/Hungary) | PCB prototyping, small-series assembly | Online verification, no tooling charges, multilingual support | 2-16 layers, ENIG/HAL finish, impedance control | 3 working days (bare board), 6 working days (assembled) |

| NCAB Group (Sweden) | PCB sourcing, prototyping, supply chain management | Global network, zero-defect quality, technical expertise | 2-24 layers, standard & high-precision PCBs | 5-12 working days |

| Proto-Electronics (France/Portugal) | PCB prototype assembly Europe, SMT assembly | 10-min online quote, 4M+ component database | 2-4 layers, lead-free finish, BGA/QFN assembly | 5-20 working days (inclusive of assembly) |

| W√ľrth Elektronik (Germany) | Flexible, rigid-flex PCBs, electronic components | Broad product portfolio, excellent customer support | Flexible PCBs, multilayer rigid boards | 7-15 working days |

| Gatema PCB (Czech Republic) | Industrial PCB prototyping, small-batch production | European compliance, environmental manufacturing | 2-8 layers, FR-4, lead-free processes | 6-10 working days |

| Tech CI Rh√īne-Alpes (France) | Aerospace/medical PCB prototypes | High-reliability, industry-specific compliance | Multilayer, high-temperature resistant materials | 8-14 working days |

| Intectiv (Slovenia) | Custom PCB prototyping, assembly services | Cost-effective, fast turnaround for low volume | 2-12 layers, standard finishes | 4-8 working days |

Types of Fast PCB Prototype Europe

- Instant Online Quoting & Design Validation: European providers offer 10-minute automated quotes for fast PCB prototype Europe projects, paired with real-time design verification. The service syncs with 4M+ component databases to check part availability upfront, supporting 24/7 self-service operations without manual follow-up.‚Äč

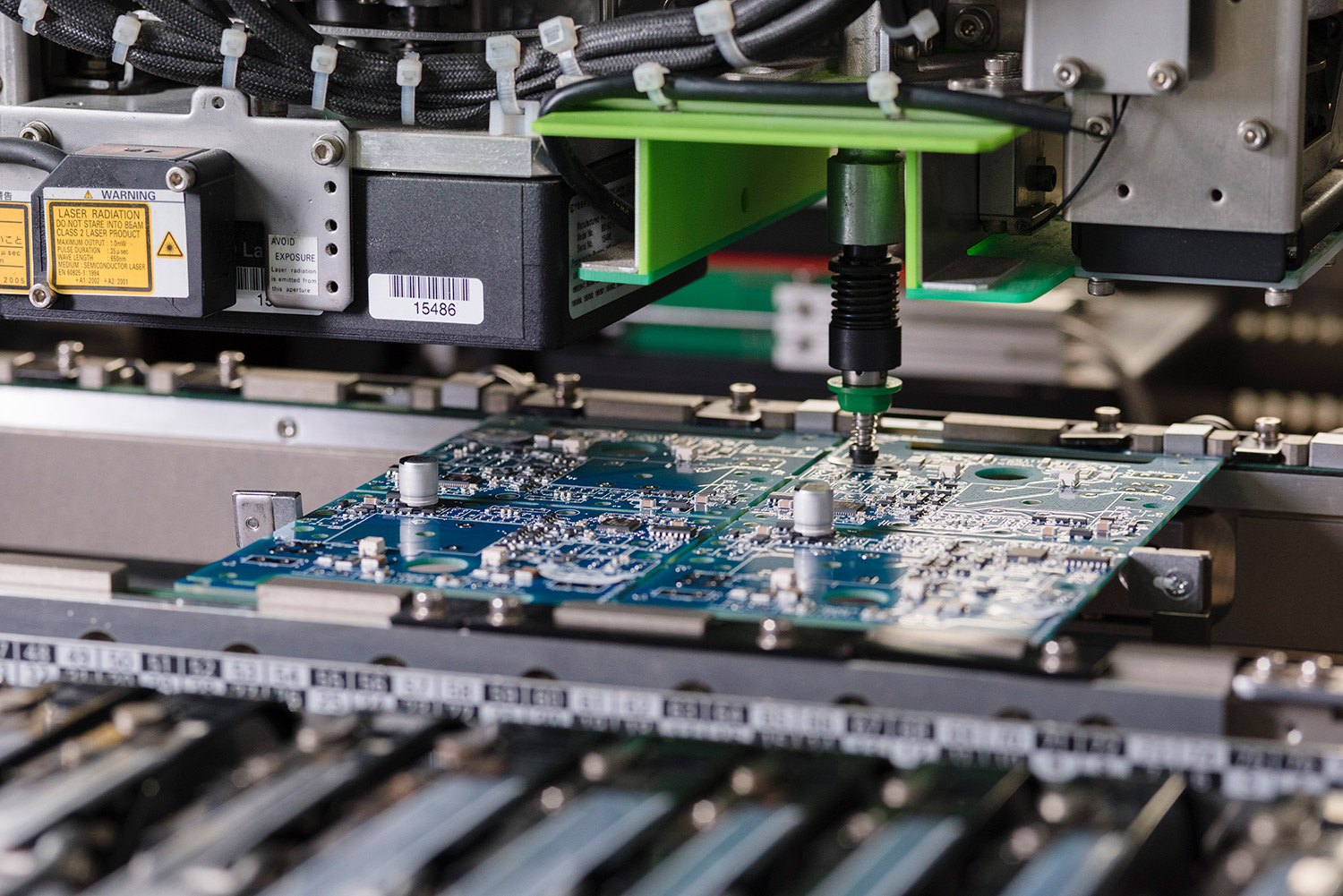

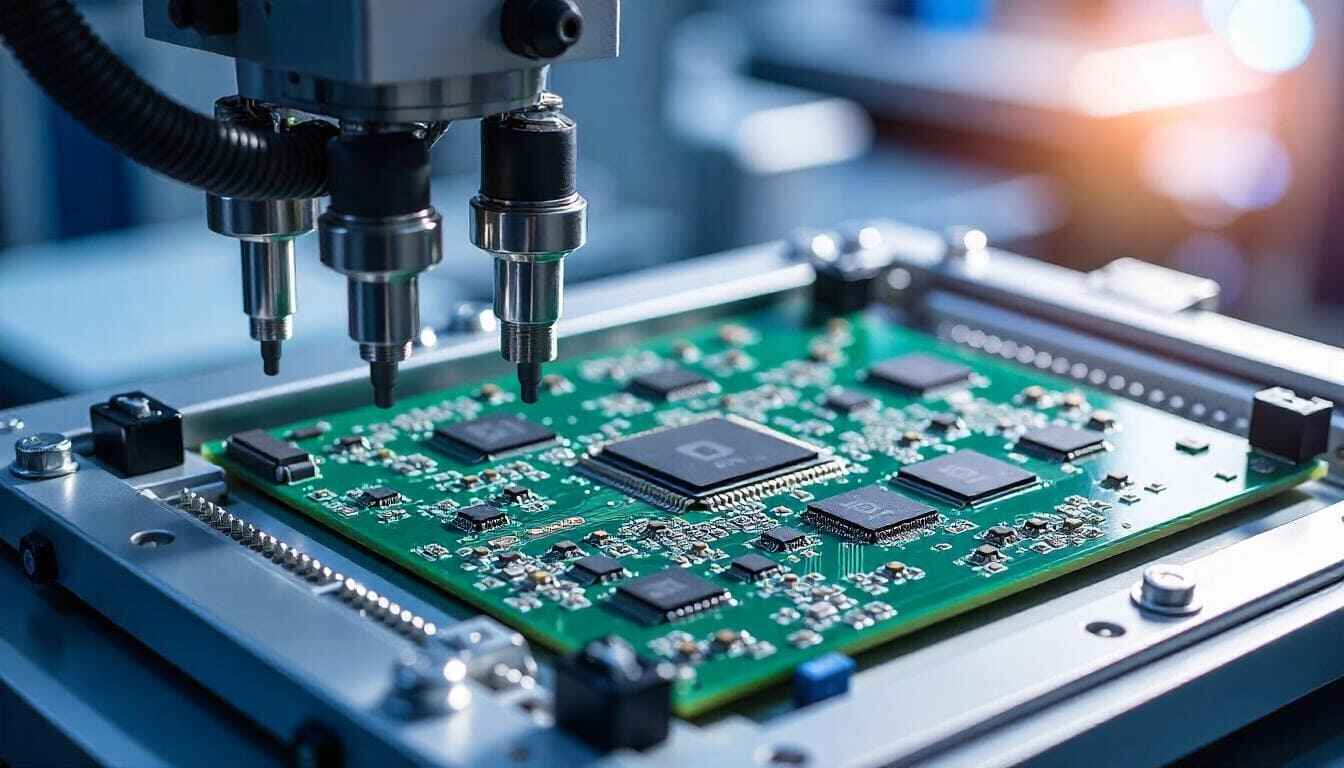

- Urgent Production Line for Express Orders: Dedicated express lines handle urgent prototype PCB Europe needs, delivering 2-4 layer simple boards in 24-48 hours. Advanced equipment like SMT smartlines and vapour phase reflow ovens ensures speed without compromising basic quality checks.‚Äč

- One-Stop PCB Prototype Assembly Europe: Integrates component sourcing, SMT assembly (including BGA/QFN processes) and multi-stage testing into a single workflow. Shortens lead times by eliminating cross-supplier coordination, with optional confidentiality agreements (NDA) for sensitive projects.‚Äč

- Pre-Production Design for Manufacturability (DFM) Analysis: Online tools pinpoint manufacturability issues early, such as impedance mismatches or pad design flaws. Reduces rework delays significantly, a critical value-add for low-volume PCB prototyping Europe projects.‚Äč

- Localized Production & Fast Delivery: Leverages facilities across Germany, France, Hungary and Portugal to enable regional fulfillment. Bare boards for fast PCB prototype Europe can reach most European regions within 3 working days, assembled prototypes within 6 working days.

Quality Standards for PCB Prototype Europe

- RoHS 2.0 Compliance

- IPC Class 2/3 Certification

- ISO 9001 Quality Management

- AS9100D for Aerospace

- IATF 16949 for Automotive

Delivery Time for PCB Prototype Service Europe

| Service Type | Layer Count | Lead Time |

| Urgent Service | 2-4 Layers | 24 Hours |

| Express Service | 2-8 Layers | 3 Working Days |

| Standard Service | 2-16 Layers | 5-7 Working Days |

| Complex Prototyping | 8-32 Layers/HDI/Ceramic | 7-14 Working Days |

| Prototype PCB Assembly Europe | 2-16 Layers | 6-10 Working Days |

Pain Points of PCB Prototype Europe

- Long lead times for specialized materials like ceramic and high-TG FR-4, delaying prototyping schedules.‚Äč

- Inconsistent quality across small-volume suppliers, leading to repeated iterations and wasted resources.‚Äč

- Language and time zone barriers when coordinating with non-local suppliers for PCB prototype service Europe.‚Äč

- Strict environmental regulations limit the use of certain materials and processes, restricting design flexibility.‚Äč

- Supply chain fragility due to reliance on imported raw materials like copper foil and epoxy resin.‚Äč

- Lack of real-time production tracking, making it hard to monitor PCB prototyping Europe progress.

Why Choose EBest(Best Technology) for PCB Prototyping Europe?

Reasons Why Choose EBest(Best Technology) for PCB Prototyping Europe:

- 24-hour urgent fast PCB prototype Europe service with 98% on-time delivery rate, solving tight schedule issues.

- 19 years of PCB production experience, with expertise in ceramic PCB and HDI prototypes (up to 32 layers, 0.1mm line width/spacing).

- Strict quality control certified by ISO9001, AS9100D, and IATF 16949, with 0.02% defect rate in prototyping.

- One-stop PCB prototype assembly Europe, covering component sourcing (4M+ verified components) and testing.

- MES system integration for 100% production data traceability, allowing real-time progress monitoring.

- Dedicated technical team for pre-production DFM analysis, reducing rework rate by 35%.

Our Quality Certifications for PCB Prototyping

- ISO9001:2015

- ISO13485:2016

- IATF16949

- AS9100D

- REACH

- RoHS

Our Lead Time for PCB Prototyping

| Layers | Normal Service | Fastest Service |

| 1 | 7 Days | 24 H |

| 2 | 8 Days | 24 H |

| 4 | 10 Days | 48 H |

| 6 | 10 Days | 72 H |

| 8 | 12 Days | 72 H |

| ‚Č•10 | TBD | TBD |

Case Studies of Europe PCB Manufacturing

Project Background:

As Europe accelerates its transition to electric vehicles (EVs), German automotive supplier Continental AG partnered with AT&S Austria to develop high-density interconnect (HDI) PCBs for next-generation EV power electronics. The project addresses the critical need for compact, thermally stable PCBs capable of handling 1,200V direct current and extreme temperature fluctuations (-40¬įC to 150¬įC) in EV powertrain systems.

Project Requirements:

- Technical Specs: 12-layer HDI with 50őľm line/space, 100ő© impedance control, and embedded capacitors for power integrity.

- Certification: IATF 16949 for automotive quality, ISO 14001 for environmental management, and EU REACH compliance.

- Lead Time: 5-day urgent prototyping, 12-day volume production (5,000 units/week).

Challenges:

- Thermal Management: High current density (30A/cm²) required innovative copper plating and thermal via arrays.

- Signal Integrity: 5G-ready high-frequency signaling (30GHz) demanded precise impedance matching and minimal crosstalk.

- Sustainability: Achieving <1% waste generation through closed-loop copper recovery and bio-based solder masks.

Solutions:

- Advanced Manufacturing: AT&S deployed its patented “mSAP+” process for sub-30őľm features, combined with AI-driven defect detection (99.8% accuracy).

- Thermal Solutions: Graphene-enhanced dielectric materials reduced thermal resistance by 40%, while micro-channel cooling integrated into PCB layers.

- Digital Twin: Real-time MES 4.0 system tracked 500+ process parameters, enabling predictive maintenance and 15% yield improvement.

Outcomes:

- Performance: Achieved 99.97% reliability in 10,000-hour accelerated life testing, with <0.1dB signal loss at 30GHz.

- Sustainability: 92% reduction in water usage and 35% lower CO‚āā emissions compared to conventional processes.

- Economic Impact: Supported Continental’s ‚ā¨2.3B EV powertrain contract, creating 800+ European jobs in R&D and manufacturing.

How to Get A Quote for Europe PCB Prototyping?

1. Prepare Design Files

- Submit Gerber files (RS-274X), Excellon drill files, and a detailed BOM (component part numbers, footprints).

- Include optional schematics (PDF), 3D models (STEP/IGES), or assembly drawings for clarity. Use tools like Eurocircuits’ Design Checker to validate files pre-submission.

2. Select European Suppliers

Regional Options:

- Germany: W√ľrth Elektronik (automotive/industrial), KSG (flex-rigid PCBs).

- UK: Tate Circuits (quick-turn prototypes), PCB Train (standard options).

- Switzerland: Optiprint (HDI/microwave PCBs).

- Netherlands: Eurocircuits (transparent pricing for 2‚Äď12 layer boards).

Certifications:

- Prioritize ISO 9001/AS9100D-certified manufacturers (e.g., Austria’s AT&S) for quality compliance.

3. Request Quotes

- Use automated tools (e.g., Eurocircuits’ calculator, PCB Train’s portal) for instant quotes by inputting parameters (layer count, material, lead time).

- For complex designs, contact suppliers directly via email for custom quotes, providing BOM and design files for a detailed breakdown.

4. Evaluate Quotes

- Analyze cost components (material, tooling, testing, shipping) and lead times (e.g., 24-hour express vs. 5-day standard).

- Review DFM reports from suppliers to identify design flaws (e.g., trace spacing issues) pre-production.

5. Confirm Order & Track Production

- Validate designs through DFM checks (e.g., minimum hole size 0.2mm).

- Confirm payment terms and logistics (DHL/FedEx for EU-wide delivery). Track progress via supplier portals (e.g., Eurocircuits’ tracker).

6. Post-Delivery Validation & Feedback

- Test electrical performance (continuity) and dimensional accuracy upon receipt.

- Provide feedback to suppliers to refine future quotes and improve collaboration.

Welcome to contact us to get a free quote if you have any request for Europe PCB prototyping: sales@bestpcbs.com.

Tags: Europe PCB prototype‚Äč, fast PCB prototype Europe, pcb prototype europe, PCB prototype service Europe‚Äč, PCB prototyping Europe, prototype PCB Europe