Electronic contract manufacturing company refers to a manufacturing partner that takes responsibility for PCB assembly, testing, and related production processes within an OEMâs electronics supply chain.

This article explains how to evaluate and choose the right electronic contract manufacturing company for PCBA projects, from early prototypes to long-term volume production.

Choosing an electronic contract manufacturing company is rarely straightforwardâespecially when PCBA quality, scalability, and long-term reliability are on the line.

Are these challenges familiar to your team?

- Unstable prototype builds: Early PCBA samples show inconsistent quality, making validation slow and unreliable.

- Poor scalability from pilot to volume: A supplier that performs well at low volume fails to maintain yield and consistency at scale.

- Limited engineering involvement: Manufacturing feedback comes too late, leading to costly design re-spins.

- Fragmented supply chain responsibility: Separate vendors for PCB assembly, testing, and system integration create coordination gaps.

- Quality system misalignment: The supplierâs quality controls do not match the reliability requirements of the end application.

These risks point to one conclusion: selecting the wrong electronic contract manufacturing company directly increases PCBA cost, risk, and time-to-market.

The right manufacturing partner addresses these challenges at the system and process level.

- Controlled prototype execution: Fast PCBA prototypes built under production-grade process controls.

- Scalable manufacturing architecture: Identical assembly processes used from pilot builds through volume production.

- Early DFM and engineering collaboration: Manufacturing risks identified and mitigated before release to production.

- Single-source PCBA accountability: One partner responsible for assembly quality, testing, and delivery.

- Process-driven quality systems: Documented, repeatable PCBA processes aligned with long-term reliability goals.

EBest Circuit (Best Technology) is an electronic contract manufacturing company centered on PCBA, not a general-purpose EMS provider. With 20 years of experience, we specialize in PCB assembly, engineering support, and scalable production for industrial, medical, and high-reliability electronics. We support customers from fast PCBA prototypes through stable volume manufacturing, with disciplined process control and engineering-driven execution. Pls feel free to contact us at sales@bestpcbs.com to discuss your PCBA requirements.

What Does an Electronic Contract Manufacturing Company Do in Modern Electronics Supply Chains?

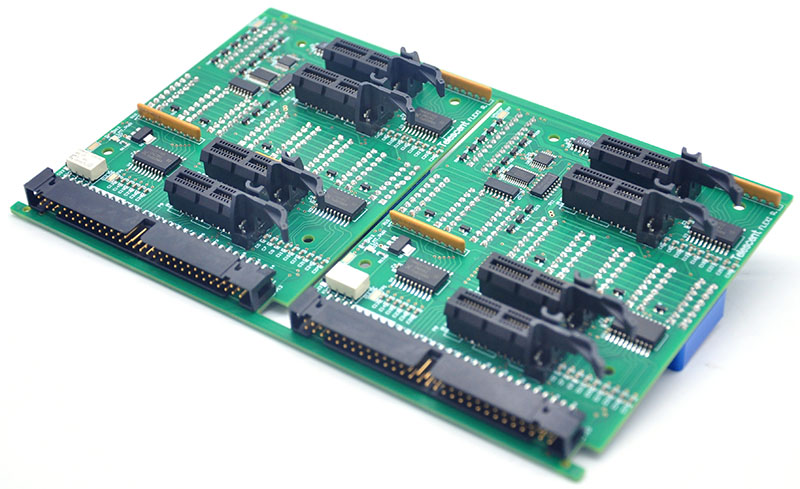

An electronic contract manufacturing company acts as the manufacturing extension of an OEM, translating designs into reliable, repeatable PCB assemblies.

Key responsibilities include:

- PCB assembly execution (SMT, THT, mixed technology)

- Process engineering and DFM support

- Production testing and inspection

- Supply chain coordination for PCBA materials

- Manufacturing scalability and yield control

In summary, the value of an electronic contract manufacturing company lies in its ability to deliver PCBA that performs consistently across the product lifecycle.

How Do Electronic Contract Manufacturing Companies Support OEMs From Prototype to Volume?

Supporting PCBA across all stages requires more than capacityâit requires process continuity.

Effective support includes:

- Rapid PCBA prototyping with documented processes

- Pilot builds that mirror production intent

- Controlled ramp-up planning

- Yield monitoring and corrective action loops

- Stable long-term manufacturing execution

Prototype success must translate directly into volume success.

What Capabilities Differentiate Leading Contract Electronics Manufacturing Companies?

Not all contract electronics manufacturing companies are equalâespecially for PCBA-intensive products.

Top-tier capabilities include:

- Advanced SMT placement accuracy

- Repeatable soldering and inspection processes

- Engineering-led DFM reviews

- Defined quality metrics and KPIs

- Clear change-control discipline

In conclusion, differentiation is driven by process maturity, not factory size.

Why Do Global OEMs Work With Electronics Contract Manufacturing Companies in China?

OEMs choose electronics contract manufacturing companies in China for reasons tied to execution capabilityânot labor cost.

Key decision factors include:

- Mature PCBA process ecosystems

- Scalable manufacturing capacity

- Dense component supply networks

- High engineering resource availability

- Proven experience with complex electronics

In short, China offers depth and scalability for PCBA when managed correctly.

How to Compare Electronics Contract Manufacturing Companies in USA vs Asia?

Geography matters only insofar as it affects manufacturing outcomes.

| Comparison Factor | USA-Based ECM | Asia-Based ECM |

|---|---|---|

| Engineering density | High | Very high |

| Cost structure | Higher | Optimized |

| Supply chain access | Limited | Extensive |

| Scalability | Moderate | Strong |

| PCBA complexity support | High | High |

Ultimately, the right choice depends on PCBA complexity, volume expectations, and lifecycle planningânot location alone.

What Should Buyers Ask When Evaluating Contract Electronic Manufacturing Companies?

Before committing, buyers should ask targeted questions.

- Can you show PCBA yield data across volumes?

- How is DFM feedback handled and documented?

- What changes between prototype and production?

- How is process drift detected and corrected?

- Who owns PCBA quality accountability?

Good questions reveal good manufacturers.

Top 10 Electronics Contract Manufacturing Companies in China

China hosts many electronics contract manufacturing companies, but leaders share common traits.

Representative manufacturers include:

- Foxconn â large-scale global electronics manufacturing

- Flex â regulated and industrial electronics

- Sanmina â high-reliability PCBA

- Pegatron â complex system assembly

- Wistron â industrial and healthcare electronics

- USI â miniaturized electronics manufacturing

- Kaifa Technology â PCBA for regulated markets

- Shennan Circuits â advanced PCB and PCBA integration

- Kinwong â rigid and rigid-flex PCB solutions

- Best Technology â PCBA-focused electronic contract manufacturing

To summarize, scale alone does not guarantee PCBA qualityâprocess discipline does.

How Do Top Electronic Contract Manufacturing Companies Ensure Quality and Scalability?

Top-tier manufacturers rely on systems, not inspection alone.

Common characteristics include:

- Documented assembly processes

- Data-driven quality control

- Engineering ownership of manufacturing outcomes

- Controlled process changes

- Long-term yield optimization

Scalability is engineeredânot assumed.

Why Choose Best Technology as Your Right Electronic Contract Manufacturing Company for Long-Term Production?

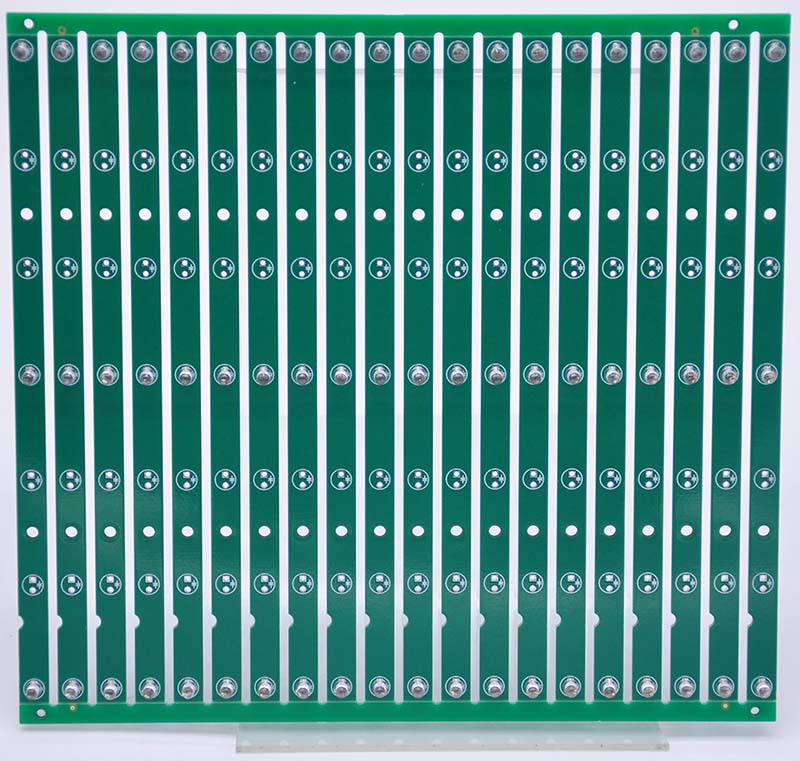

Best Technology is an electronic contract manufacturing company built around PCBA excellence.

- PCBA-first engineering mindset

- Production-grade prototypes

- Scalable, repeatable assembly processes

- Transparent quality metrics

- Long-term manufacturing partnership focus

We are not a âdo-everythingâ ECMâwe are a PCBA-driven manufacturing partner.

Overall, electronic contract manufacturing company selection directly determines the success, reliability, and scalability of PCBA projects. Choosing the right partner requires evaluating process maturity, engineering involvement, and long-term manufacturing disciplineânot just capacity or geography. EBest Circuit (Best Technology) combines PCBA-focused expertise, disciplined processes, and scalable execution to support OEMs from prototype to production. For PCBA inquiries and manufacturing discussions, pls feel free to contact us via sales@bestpcbs.com.

Tags: Contract Electronic Manufacturing Companies, Contract Electronics Manufacturing Companies, Electronic Contract Manufacturing Companies, Electronic Contract Manufacturing Company, Electronics Contract Manufacturing Companies in China, Electronics Contract Manufacturing Companies in USA, Top Electronic Contract Manufacturing Companies