A ‚Äčcomputer printed circuit board (PCB)‚Äč‚Äč is the foundational platform that interconnects and supports electronic components in computing devices, enabling everything from basic logic operations to complex data processing. This comprehensive guide explores the critical aspects of computer PCBs, from fundamental definitions and types to material selection and quality assurance, ultimately directing you to reliable solutions.

Are you struggling to find a dependable partner for your ‚Äčcomputer PCB‚Äč projects? Sourcing high-quality, reliable printed circuit boards for computers presents significant challenges.

- ‚ÄčInconsistent Quality and Reliability:‚Äč‚Äč Receiving boards with hidden defects, poor soldering, or unreliable electrical performance that lead to system failures.

- ‚ÄčDifficulty with Complex, High-Density Designs:‚Äč‚Äč Finding a manufacturer capable of handling the fine lines, microvias, and complex layer stacks required for modern motherboards, GPUs, and servers.

- ‚ÄčUncertainty in Material Selection:‚Äč‚Äč Confusion about choosing the right substrate material (e.g., FR-4, High-Tg, Rogers) to meet thermal, electrical, and mechanical demands.

- ‚ÄčChallenges in Meeting Certifications and Standards:‚Äč‚Äč Navigating the stringent requirements for certifications like UL, ISO, and IPC Class 3, especially for critical applications.

- ‚ÄčUnresponsive Suppliers and Poor Communication:‚Äč‚Äč Experiencing delays, lack of technical support, and poor communication throughout the fabrication and assembly process, jeopardizing project timelines.

The key is to collaborate with computer printed circuit board manufacturers that possesses deep expertise in ‚Äčcomputer printed circuit board‚Äč fabrication and a commitment to excellence.

- ‚ÄčRigorous Quality Control Systems:‚Äč‚Äč Implementing a full suite of electrical testing (Flying Probe, Fixture) and automated optical inspection (AOI) to ensure every board meets specifications.

- ‚ÄčAdvanced Manufacturing Capabilities:‚Äč‚Äč Utilizing state-of-the-art equipment for HDI, controlled impedance, and multilayer PCBs (up to 30+ layers) to support the most complex ‚Äčcomputer PCB board‚Äč designs.

- ‚ÄčExpert Material Guidance:‚Äč‚Äč Providing expert consultation on laminate selection to optimize performance for signal integrity, thermal management, and cost-effectiveness.

- ‚ÄčCompliance and Certification Assurance:‚Äč‚Äč Holding relevant certifications and having a deep understanding of industry standards to guarantee that boards, especially the ‚Äčmain printed circuit board in a computer, are built to the highest reliability classes.

- ‚ÄčDedicated Engineering Support and Project Management:‚Äč‚Äč Offering responsive communication, DFM analysis, and a single point of contact to ensure a smooth, transparent process from quote to delivery.

As a professional PCB manufacturer with a focus on high-performance and complex boards, EBest Circuit (Best Technology) has built our reputation on delivering superior quality, reliability, and technical support for clients worldwide. Our expertise spans from standard ‚Äčcomputer PCB‚Äč to advanced ‚ÄčAI computing power PCB‚Äč solutions. For your computer PCB needs, pls feel free to contact us at sales@bestpcbs.com.

What is Computer Printed Circuit Board?

In simple terms, a ‚Äčcomputer printed circuit board‚Äč is the physical base upon which the core components of a computer are mounted and interconnected. It provides both mechanical support and electrical pathways for components like the CPU, RAM, and storage to communicate.

- ‚ÄčThe Core Function:‚Äč‚Äč The primary purpose of a ‚ÄčPCB in a computer‚Äč is to replace a mass of tangled wiring with a compact, organized, and reliable set of pre-designed copper tracks etched onto a non-conductive substrate. This allows for miniaturization, repeatable manufacturing, and stable electrical performance.

- ‚ÄčKey Components on a Computer PCB:‚Äč‚Äč A typical ‚Äčcomputer PCB, such as a motherboard, will host critical components including the CPU socket, memory slots, chipset, power regulation modules, and connectors for peripherals. The design and quality of the PCB directly impact the speed, stability, and overall performance of the computer.

In essence, the ‚Äčcomputer printed circuit board‚Äč is the central nervous system of any computing device, from a simple ‚Äčcomputer mouse PCB‚Äč to a sophisticated server motherboard.

Computer Printed Circuit Board vs PCB: What are the Difference?

This is a common point of confusion, but the distinction is straightforward. Essentially, there is no technical difference; it is a matter of specificity.

- PCB‚Äč stands for Printed Circuit Board. It is a universal term for any board that provides electrical connections between components. PCBs are used in virtually all electronics, from calculators and televisions to medical devices.

- A ‚Äčcomputer printed circuit board‚Äč is simply a PCB that is designed specifically for use in a computing device. When we say “‚Äčcomputer PCB,” we are referring to the application of the board. The ‚Äčmain printed circuit board in a computer‚Äč is called the motherboard, while other ‚Äčtypes of circuit board‚Äč inside the case include GPU boards, network cards, and storage controller cards.

Therefore, “‚Äčcomputer printed circuit board vs PCB‚Äč” is not a comparison of two different objects. A computer PCB is a type of PCB. The term “computer PCB” implies certain design requirements, such as high-speed data transmission, multi-layer construction, and robust power delivery, which are characteristic of computing hardware.

What is the Type of Computer Printed Circuit Board?

Computers utilize a variety of PCB types, each suited to a specific function. The ‚Äčtypes of circuit board‚Äč found in a computer system are categorized mainly by their structure and number of layers.

- ‚ÄčSingle-Sided PCBs:‚Äč‚Äč The simplest type, with components on one side and conductive traces on the other. These are low-cost and are often used in simpler peripherals like a basic ‚Äčcomputer mouse PCB‚Äč or within power supplies like a ‚Äčcomputer UPS PCB board.

- ‚ÄčDouble-Sided PCBs:‚Äč‚Äč Components are mounted on both sides of the substrate, with plated-through holes connecting the circuits. This offers more complexity in a compact space and is common in many internal cards and modules.

- ‚ÄčMulti-Layer PCBs:‚Äč‚Äč These are the standard for core computing components. They consist of three or more layers of copper traces separated by insulating material. A modern motherboard is a complex multi-layer PCB, often with 8, 12, or even more layers to route all the necessary signals for the CPU, memory, and PCIe slots. This is crucial for the ‚Äčmain printed circuit board in a computer.

- ‚ÄčHDI (High-Density Interconnect) PCBs:‚Äč‚Äč HDI boards feature finer lines, microvias, and higher connection density. They are essential for space-constrained, high-performance devices like laptops, tablets, and advanced GPUs, pushing the boundaries of ‚ÄčPCB computing‚Äč power.

- ‚ÄčRigid and Rigid-Flex PCBs:‚Äč‚Äč Most ‚Äčcomputer PCB boards‚Äč are rigid. However, rigid-flex PCBs, which combine rigid and flexible substrates, are used in innovative designs like foldable laptops or to connect screens and keyboards in a way that saves space and improves durability.

How to Choose the Right Printed Circuit Board in Computer Projects?

Selecting the appropriate ‚Äčprinted circuit board in computer‚Äč projects is critical for performance, cost, and reliability. The choice depends on the project’s specific requirements.

- ‚ÄčDetermine the Application’s Demands:‚Äč‚Äč Is this for the ‚Äčmain printed circuit board in a computer‚Äč (a motherboard), an add-in card (GPU), a storage device (SSD), or a peripheral (computer mouse PCB)? The application dictates the required performance, size, and layer count.

- ‚ÄčAssess Signal Speed and Integrity:‚Äč‚Äč High-speed computing requires careful management of signal integrity. For CPUs and memory, a multi-layer PCB with controlled impedance is non-negotiable. This is a key consideration for ‚ÄčAI computing power PCB.

- ‚ÄčEvaluate Thermal Management Needs:‚Äč‚Äč High-performance components generate heat. The PCB material must have a high Thermal Decomposition Temperature (Tg). For extreme cases, metal-core or specialized ceramic-based PCBs may be necessary.

- ‚ÄčConsider Mechanical Constraints:‚Äč‚Äč The physical size and shape of the final product matter. A compact laptop motherboard will likely need HDI technology, while a desktop motherboard has more space but requires rigidity and strength to hold heavy components.

- ‚ÄčBalance Performance with Budget:‚Äč‚Äč Advanced materials and higher layer counts increase cost. It’s important to choose a PCB that meets the technical requirements without over-specifying, ensuring the project remains economically viable.

Computer Mouse PCB: Design Considerations

The computer mouse PCB is a compact, specialized application where space, power, and cost constraints intersect with user experience requirements. While less complex than a motherboard, its design involves precise electrical and mechanical considerations.

1. Miniaturization and Layout Optimization

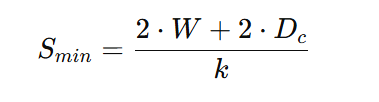

Mouse PCBs are usually double-sided to maximize component density. Designers often calculate trace spacing and routing density using the formula for minimum trace pitch to prevent crosstalk:

Where:

- Smin = minimum spacing between traces (¬Ķm)

- W = trace width (¬Ķm)

- Dc‚Äč = dielectric thickness between layers (¬Ķm)

- k = coupling factor based on acceptable crosstalk (typically 3‚Äď5)

This ensures signal integrity even in tight spaces.

2. Low Power Consumption

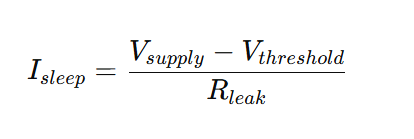

For wireless mice, power efficiency is critical. Designers optimize power planes and voltage regulation to minimize leakage. The sleep mode current can be estimated using:

Where:

- Isleep‚Äč‚Äč = standby current (A)

- Vsupply = supply voltage

- Vthreshold‚Äč = voltage at which circuits enter sleep mode

- Rleak = leakage resistance of passive components

PCB layout is optimized to reduce parasitic leakage paths, especially around the microcontroller and optical sensor.

3. Sensor Precision and Signal Integrity

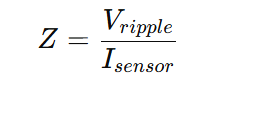

The optical sensor requires a stable, low-noise power supply. Designers calculate power plane impedance to reduce voltage ripple using:

Where:

- Z = target impedance of power distribution network

- Vripple‚Äč = maximum allowable voltage ripple

- Isensor = current drawn by optical sensor

Decoupling capacitors are strategically placed near the sensor IC, often in 0.1 ¬ĶF to 10 ¬ĶF ranges, to filter high-frequency noise.

4. Mechanical Durability

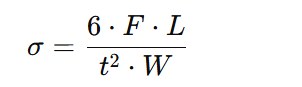

Mouse PCBs experience repeated mechanical stress from clicks and movement. The PCB laminate selection is crucial. Designers calculate bending stress for small flex areas (like scroll wheel assemblies) using:

Where:

- ŌÉ = bending stress (Pa)

- F = applied force (N)

- L = unsupported length of PCB (m)

- t = board thickness (m)

- W = board width (m)

Solder joints and micro-switch pads are reinforced with via stitching or thermal relief patterns to avoid fatigue over millions of clicks.

5. Thermal Management

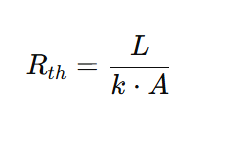

Even low-power mice generate heat near LEDs and ICs. Designers ensure thermal vias connect top-layer heat-generating components to inner copper planes to dissipate heat efficiently. The approximate via thermal resistance can be estimated as:

Where:

- Rth = thermal resistance (¬įC/W)

- L = via length (m)

- A = cross-sectional area (m²)

- k = copper thermal conductivity (~400 W/m·K)

This prevents temperature-induced drift in optical sensors and microcontrollers.

In conclusion, designing a successful computer mouse PCB requires careful consideration of miniaturization, power efficiency, signal integrity, mechanical durability, and thermal management. Using engineering formulas and layout strategies ensures optimal performance, long product life, and a responsive user experience. Early collaboration with experienced PCB manufacturers like EBest Circuit (Best Technology) guarantees that both electrical and mechanical requirements are met.

What is the Best Material for Computer Printed Circuit Board?

There is no single “best” material; the ideal choice depends on the performance and cost targets of the specific ‚Äčcomputer PCB.

- ‚ÄčFR-4:‚Äč‚Äč This is the most common PCB substrate. Standard FR-4 is suitable for many computer applications, including consumer-grade motherboards and add-in cards. For better performance, High-Tg FR-4 is used, which withstands higher temperatures, making it suitable for lead-free soldering and better thermal reliability.

- ‚ÄčHigh-Speed/Low-Loss Laminates:‚Äč‚Äč For very high-frequency signals (e.g., in high-end servers, networking equipment, and ‚ÄčAI computing power PCB), materials like Rogers or Taconic are used. They have a lower dielectric constant (Dk) and dissipation factor (Df), which minimizes signal loss and distortion.

- ‚ÄčCeramic-Based Substrates:‚Äč‚Äč In extreme thermal environments, such as near a high-performance CPU or GPU, ceramic PCBs (e.g., Aluminum Nitride, Alumina) offer excellent thermal conductivity to draw heat away from components, though at a higher cost.

For most general-purpose ‚Äčcomputer printed circuit board‚Äč applications, High-Tg FR-4 represents the best balance of performance, reliability, and cost.

What Certifications are Required for Making Main Printed Circuit Board in a Computer?

Producing the ‚Äčmain printed circuit board in a computer‚Äč requires adherence to strict quality and safety standards. Key certifications include:

- ‚ÄčISO 9001:‚Äč‚Äč Certifies that the manufacturer has a consistent Quality Management System (QMS) in place.

- ‚ÄčIATF 16949:‚Äč‚Äč This is the QMS standard for the automotive industry, and its rigorous requirements are often sought after for high-reliability computer applications.

- ‚ÄčUL Recognition (UL 94):‚Äč‚Äč Underwriters Laboratories certification ensures the PCB base material meets specific flammability safety standards.

- ‚ÄčIPC Standards:‚Äč‚Äč Adherence to IPC standards is crucial. For a high-reliability product like a motherboard, compliance with ‚ÄčIPC-A-600‚Äč (acceptability of printed boards) and ‚ÄčIPC-6012‚Äč (performance specification for rigid PCBs) at ‚ÄčClass 3‚Äč is typically required. Class 3 ensures the highest level of quality for products where continuous performance or performance-on-demand is critical, such as in a computer’s main PCB.

These certifications provide assurance that the ‚Äčcomputer printed circuit board manufacturers‚Äč follow documented processes and produce reliable, safe products.

How to Ensure Quality in Computer Printed Circuit Board Fabrication?

Ensuring quality in ‚Äčcomputer printed circuit board‚Äč fabrication is a multi-stage process that involves rigorous checks and testing.

- ‚ÄčDesign for Manufacturability (DFM) Check:‚Äč‚Äč Before production begins, the manufacturer should perform a thorough DFM analysis to identify and resolve potential design issues that could affect yield or performance.

- ‚ÄčIn-Process Quality Control:‚Äč‚Äč This includes Automated Optical Inspection (AOI) to check for defects like shorts or opens after etching and solder mask application.

- ‚ÄčElectrical Testing:‚Äč‚Äč 100% electrical testing is mandatory. This is done either with Flying Probe testers (for prototypes and small batches) or a dedicated test fixture (for mass production) to verify that all networks are connected correctly without shorts or opens.

- ‚ÄčFinal Inspection and QA:‚Äč‚Äč A final visual inspection and conformance check against the customer’s specifications are performed. Certifications like ISO 9001 ensure this process is systematic and repeatable.

For a manufacturer, quality is not an afterthought but an integral part of the entire ‚Äčcomputer PCB‚Äč fabrication workflow.

Why Choose EBest Circuit (Best Technology) as One of Your Main Computer Printed Circuit Board Manufacturers?

When searching for where to get reliable ‚Äčcomputer printed circuit board solutions, partnering with an experienced and capable manufacturer is paramount. EBest Circuit (Best Technology) stands out for several key reasons.

- ‚ÄčProven Expertise in Complex Projects:‚Äč‚Äč We have a track record of successfully producing advanced, multi-layer, and HDI PCBs for demanding computing environments, including ‚ÄčAI computing power PCB applications.

- ‚ÄčState-of-the-Art Manufacturing Facility:‚Äč‚Äč Our factory is equipped with advanced machinery capable of producing high-precision, high-reliability boards that meet the stringent requirements of modern computers.

- ‚ÄčUncompromising Commitment to Quality:‚Äč‚Äč We implement a rigorous quality management system, adhering to relevant IPC classes and performing extensive electrical and optical testing on every batch to ensure zero-defect delivery.

- ‚ÄčExpert Technical Support:‚Äč‚Äč Our engineering team provides proactive support, from initial DFM advice to material selection, acting as an extension of your R&D department to optimize your ‚Äčcomputer PCB design for performance and manufacturability.

- ‚ÄčResponsive and Reliable Service:‚Äč‚Äč We understand the importance of timelines. We offer transparent communication and on-time delivery, ensuring your projects move forward smoothly without unexpected delays.

‚ÄčIn summary, the ‚Äčcomputer printed circuit board‚Äč is the indispensable backbone of all modern computing, determining the functionality, speed, and reliability of the entire system. This guide has detailed the critical considerations for sourcing and designing high-quality PCBs for computer applications. For solutions that meet the highest standards of quality, technical capability, and service, pls feel free to contact our team today at sales@bestpcbs.com to discuss your project requirements. We are committed to being your trusted partner for all your ‚Äčcomputer PCB‚Äč needs.

Tags: Computer Printed Circuit Board, computer printed circuit board manufacturers, Computer printed circuit board vs pcb