PCB board made in china is a hot topic for engineers who need speed, value, and reliability. This guide uncovers what buyers truly care about when sourcing a PCB board made in China while showing how EBest Circuit (Best Technology) solves customers needs with smart processes and a friendly team.

EBest Circuit (Best Technology) is a PCB Manufacturer China, providing quick prototype, PCB board fabrication, and turnkey assembly services to worldwide clients & markets. As an R&D-driven company, we believe that innovation is paramount for us to get long-term developments. Our company has got some invention patents and utility model patents each year. If you need a PCB Board made in China, just feel free to contact us via sales@bestpcbs.com. We are happy to provide optimum PCB board solutions for your projects.

Which company makes PCB board made in china?

China hosts thousands of board factories, yet only a handful handle complex work with tight control. Names on the top 10 PCB manufacturers in China lists often include large public firms focused on huge volumes. However, midâsize partners shine when projects vary. EBest Circuit (Best Technology) sits in this sweet spot. We run flexible lines, cover rigid, flex, and ceramic, and keep inâhouse assembly under one roof. Our engineers review data up front to avoid shorts, opens, or warpage. That review, plus IPCâclass workmanship, keeps rework low and firstâpass yield high.

Who is the biggest manufacturer of PCB board made in china?

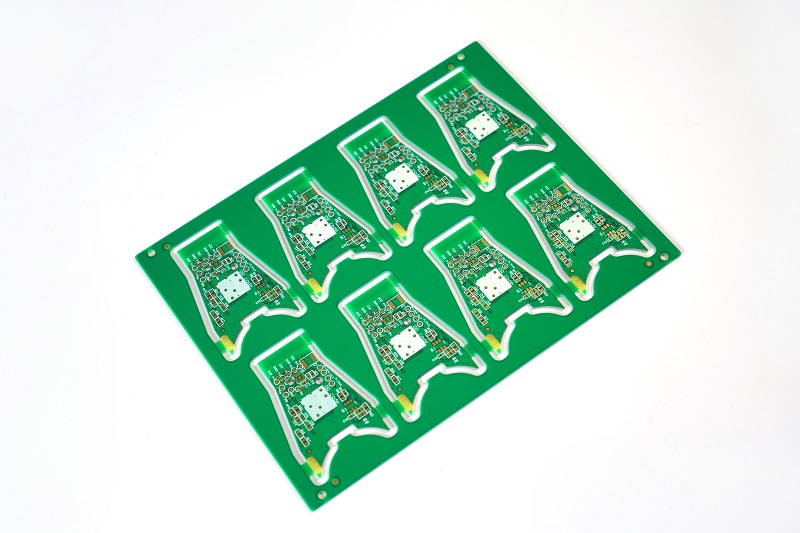

By revenue, the biggest player is a wellâknown conglomerate whose plants span multiple provinces. Yet being the largest is not always ideal for quick prototype or smallâbatch jobs. Giant lines favor millions of panels. When you need PCB board made in china in ten days, you want focus, not size. EBest Circuit (Best Technology) addresses this need with quickâchange tooling, smart MES, and 3,000 mÂČ of floor space that switches from sample to mass without delay. That flexibility keeps your launch on schedule.

Can I get a quick prototype of a PCB board made in China?

Yes, and it can be faster than local shops thanks to roundâtheâclock production and export hubs near main airports. EBest Circuit (Best Technology) offers a quick prototype service that ships rigid twoâlayer samples in 48 hours and complex sixâlayer stacks in five days for urgent PCB board projects. We achieve this speed by:

- Keeping core materials like FRâ4, Rogers, and aluminum nitride in stock.

- Running Xâray drill registration to avoid misâhits that would otherwise force remakes.

- Employing courier pickup direct from the plant to cut domestic legs.

With these steps, your first item arrives earlier, giving you more room for design tweaks.

What is the cost of a PCB board made in China for small batches?

Cost depends on layer count, size, finish, and test coverage. For instance, a 100 mm Ă 100 mm fourâlayer board with ENIG finish in ten pieces often lands around USD 80 including SMT stencil. Transparent pricing at EBest Circuit (Best Technology) lists prototype and final electrical assembly separately, so you see value in each line. Because we manage a trusted supplier base for copper foil, raw material swings stay modest. We also offer bundled assembly, saving extra freight legs and cutting total landed cost. That means that your PCB board fabrication and PCB board assembly order will be finished under the same roof at our factory in China. That saves your money, and time and guarantees the PCB board quality.

How long does it take to make a PCB board made in china?

Lead time splits into fabrication and logistics. Standard fabrication times follow:

- Twoâlayer: 3â4 working days.

- Fourâlayer: 5â6 working days.

- Sixâlayer and up: 6â8 working days.

These figures assume full test and IPCâAâ600 class 2. Add 1â2 days for ENEPIG or hard gold. Air freight from Shenzhen to the United States usually takes 3â4 days. Hence, a complete eightâlayer ENIG job can reach your lab in under two weeks.

Where to find manufacturers of PCB board made in China?

You can browse trade fairs, B2B platforms, or industrial clusters like Shenzhen Baoâan or Jiangsu Kunshan. Yet vetting takes time. A faster path is contacting EBest Circuit (Best Technology) directly. Our sales engineers answer in under 12 hours, share DFM feedback, and send a live plant tour video so you see machines, not stock photos. Transparency builds trust and speeds vendor approval on your side.

How to ensure quality when ordering a PCB board made in China?

Success rests on three pillars: design review, process control, and final test.

- Design review. We perform full DFM and impedance checks before drill hits copper. This stops common faults such as solder bridges or acid traps.

- Process control. Tight lamination curves, AOI after every imaging stage, and Xâray for BGA registration shrink defect chances.

- Final test. Every board passes flyingâprobe or bedâofânails electrical test plus 100% visual at microscope stations.

We hold ISOÂ 9001, ISO 13485, IATFÂ 16949, and AS9100D. We have cooperated with customers from all walks of life. High reliability and fast turnaround are the outlets of EBest Circuit (Best Technology).

Why choose EBest Circuit (Best Technology) for your PCB board made in China?

EBest Circuit (Best Technology) has some shiny points as below.

- No more design mishaps. We audit Gerber and CAD files early, fixing shorts or opens before they cost time.

- Stable smallâbatch flow. Flexible lines even when order size is low.

- Material traceability. Approved vendors supply highâTG FRâ4, highâfrequency PTFE, and ceramic, locking in stable dielectric values.

- Advanced checks. AOI, Xâray, and SPI catch issues fast, trimming scrap.

- Endâtoâend service. From design support to SMT assembly, one team covers every step. You focus on product, not paperwork.

In short, EBest Circuit (Best Technology) blends modern equipment with a professionalism. The result is dependable PCB boards, on time, every time.

A PCB board made in china offers speed, flexibility, and budget benefits when you pick a proven partner. EBest Circuit (Best Technology) removes worry by pairing strict quality systems with smart automation and quick communication. Our flexible lines switch from prototype to mass build without stress. Reach out to us at sales@bestpcbs.com for specific solutions for your projects.

Tags: PCB Board Made In China, PCB Manufacturer China, Quick Prototype