Bare printed circuit board is the foundation of every electronic device. It’s the blank canvas where circuits begin their journey before components get mounted. If youâre looking for a reliable supplier, this guide will give you the clarity and confidence you need.

EBest Circuit (Best Technology) is one of the bare PCB board manufacturers in China. We offer complete certificates, covering ISO 9001, ISO 13485, IATF 16949, and AS9100D, along with full compliance announcements with RoHS, and REACH regulations. This ensures high-quality production and hassle-free imports for our clients. You will get a board that works the first time, saving time and repairs. As the original bare printed circuit board factory, if you have any interest, welcome to come to visit us at any time. For inquiries, please reach out to us at sales@bestpcbs.com.

What is a bare printed circuit board?

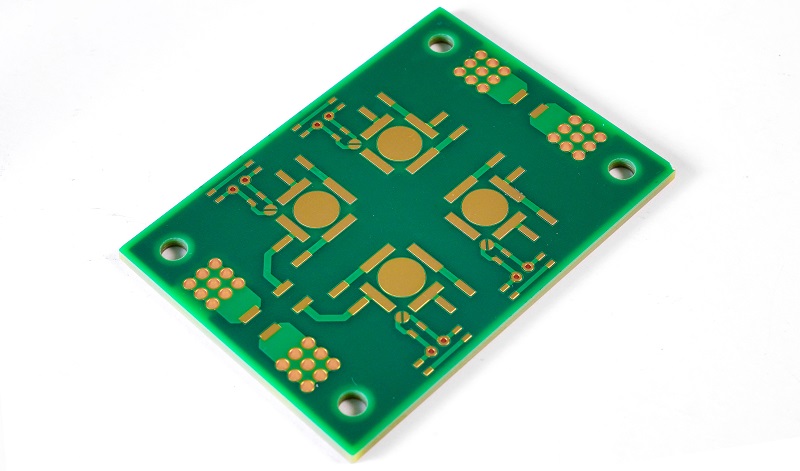

A bare printed circuit board refers to a PCB without any components. It consists only of the insulating substrate and copper traces. This version hasnât yet been assembled or populated, but it’s already patterned to connect future components.

What is the difference between bare printed circuit board and PCB?

The term PCB (Printed Circuit Board) refers to the board itself, which may be bare or assembled. A bare printed circuit board specifically has no components soldered to it yet, serving as the initial substrate in production. The assembled board with components is typically called a PCBA (PCB Assembly).

Is a motherboard a bare printed circuit board?

No, a motherboard is a fully populated PCB. It contains various chips, ports, and circuits, making it ready for operation. A bare board comes before that stage in the process.

What is a zero PCB board?

A zero PCB board, often used for prototyping, is a general-purpose PCB with pre-drilled holes and copper pads. It allows manual component placement for testing circuits without full production.

What is a PCB teardrop?

A PCB teardrop refers to a design feature that adds extra copper at trace-to-pad or trace-to-via junctions. It helps reduce stress and improves connection durability, especially in mechanical or thermal environments.

What are the three types of printed circuit boards?

The three major types are single-sided, double-sided, and multilayer PCBs. Single-sided has copper on one side, double-sided on both, and multilayer has several layers stacked together with internal routing.

What is the difference between THT and SMT?

Through-hole technology (THT) uses holes drilled in the board for component leads, while surface-mount technology (SMT) mounts components directly on the surface. SMT is faster and more space-efficient than THT.

How to check bare printed circuit board?

Checking a bare board involves visual inspection and electrical testing. At EBest Circuit (Best Technology), we use machine vision systems to detect scratches, oxidation, short circuits, and poor alignment. We also run automated optical inspection and flying probe tests to ensure high quality.

Why should you choose EBest Circuit (Best Technology) as one of your trusted Bare PCB Board Manufacturers?

At EBest Circuit (Best Technology), we understand what customers worry about most. Issues like surface defects, open or short circuits, pad misalignment, or copper layer inconsistencies can ruin a project. Weâve tackled these problems head-on.

- First, we invest in advanced machine vision systems to detect defects like scratches, stains, or oxidation spots. With optimized lighting techniques, our inspections catch more than the eye can see.

- Second, our line width accuracy is controlled by refining our etching process. We maintain etchant temperature and flow precisely. Equipment is inspected regularly to avoid route breaks or shorts.

- For hole position defects, we use precision CNC drilling machines. We adjust spindle speed and use high-grade drill bits to ensure accurate, burr-free holes.

- Cleanliness is a key focus. We have anti-contamination procedures at every step. Materials are screened, and operators follow strict protocols to avoid dust, ink residue, or foreign objects like fibers and debris.

- Compatibility issues with CAD netlists or Gerber files? No problem. Our engineers review and simulate every job. Data is cross-verified to avoid mismatch between design files and machine code.

Beyond our technical strength, weâre easy to work with. Our pricing is fast, and our delivery is on time. Communication is fast, with English-speaking engineers on hand to guide your order. Whether you need rigid, flexible, or metal-clad PCBs, we deliver consistency and confidence.

To put it simply, whether youâre building a general-purpose PCB or developing a high-performance application, it all starts with a trusted bare PCB board manufacturer. EBest Circuit (Best Technology) stands out for its strict process control, defect detection, premium quality, and customer support.

We listen to your concerns. Whether itâs a scratch, offset hole, or inconsistent copper layer, we prevent issues before they reach you. With tailored solutions and a focus on cleanliness, alignment, and reliability, we help your ideas come to lifeâclean, precise, and on time. A warm welcome to contact EBest Circuit (Best Technology) at sales@bestpcbs.com to get a fast, accurate quote for your next bare printed circuit board.

Tags: Bare PCB Board Manufacturers, Bare Printed Circuit Board, Premium Quality