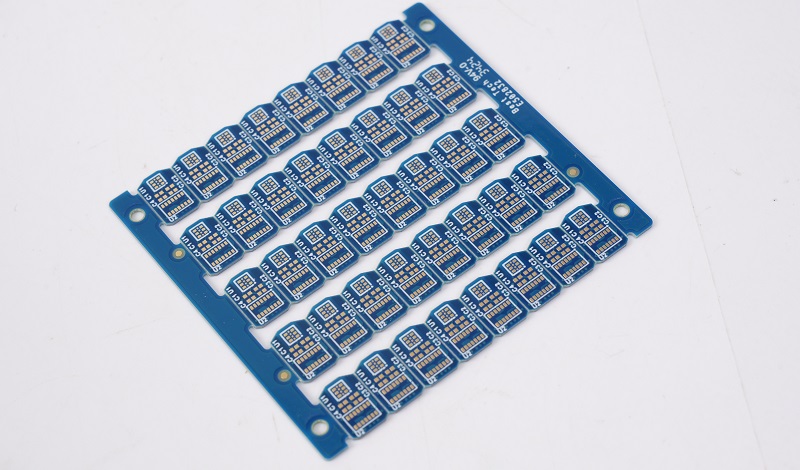

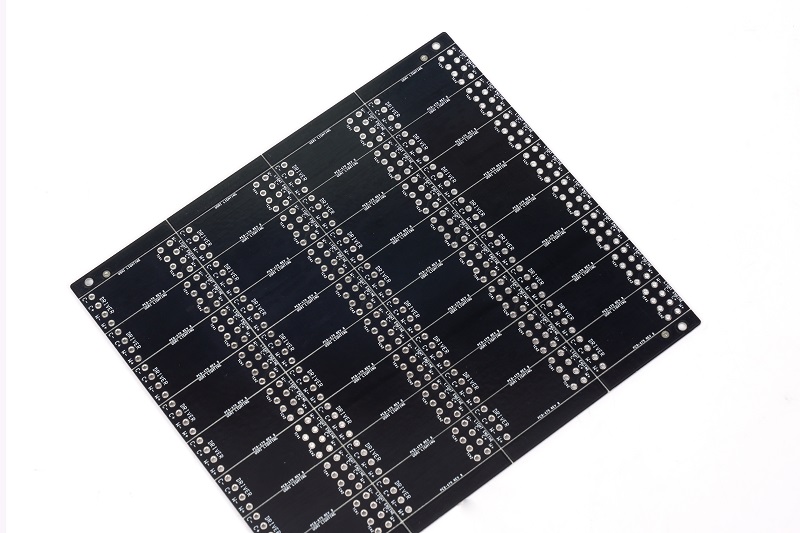

Prototype PCB board manufacturer is the first step for any project that demands fast testing, real-time feedback, and design validation. Whether you’re working on a wearable, a drone, or a medical device, the speed and quality of your prototype can determine your product’s success.

EBest Circuit (Best Technology) is your reliable partnerâ on prototype PCB board and prototype PCB assembly. We provide innovative solutionsâ to global customers. And we assure you of a high-quality PCB prototype and fast turnaround PCB prototype manufacturing service. Our factory has special lines to manage the PCB prototype orders with no MOQ. If you have any PCBs need us to prototype, just feel free to let us know at sales@bestpcbs.com.

What is the Best Prototype PCB Board Manufacturer?

The best prototype PCB board manufacturer offers more than just production. You need a partner that provides fast turnaround, excellent material options, and design-for-manufacturing support. EBest Circuit (Best Technology) stands out by controlling small-batch costs, offering transparent online quotes, and providing technical guidance throughout the process.

Who is Prototype PCB Board Manufacturer?

A prototype PCB board manufacturer is a company that fabricates sample printed circuit boards used for testing new designs. These are often short-run, quick-turn PCBs used before mass production. They must deliver consistency and adapt to complex design changes rapidly, which is what EBest Circuit (Best Technology) focuses on.

Who is the Largest Prototype PCB Board Manufacturer in the World?

While global giants like TTM Technologies and AT&S (Austria Technologie & Systemtechnik AG) have scaled massively, smaller specialist firms like EBest Circuit (Best Technology) provide more customization, faster communication, and tighter quality controlâespecially for industries requiring certified manufacturing and real-time engineering support.

What is the Difference Between Prototype PCB Board and Assembly?

Prototype PCB board refers to the blank board itselfâmade from FR4, ceramic, aluminum, or Rogers. Prototype PCB assembly means the board has components soldered to it. Manufacturers like EBest Circuit (Best Technology) offer both services, ensuring one-stop solutions with lead-time control.

How Does a Prototype PCB Board Work?

It functions like any other PCB, but for test runs only. Engineers use it to check signal integrity, power distribution, and fit within the product case. By catching errors early, it helps you avoid costly revisions in mass production. EBest Circuit (Best Technology) enhances this with early DFM feedback.

How to Make a Prototype PCB Board?

Start by uploading your Gerber files to a trusted PCB prototype online portal. Choose layers, materials, and surface finish. EBest Circuit (Best Technology) offers clear online quotes, fast DFM checks, and live technical supportâmaking the process smooth and risk-free. We also reduce steps by providing component sourcing and assembly under one roof.

How Do I Find the Prototype PCB Board Manufacturer?

Search for manufacturers with local or U.S. production if you’re targeting fast delivery. Use keywords like PCB prototype USA, Proto PCB Manufacturer No MOQ, or PCB Prototype Manufacturing Service. Check reviews, certifications, and case studies. EBest Circuit (Best Technology), with certifications like ISO 9001, IATF 16949, and AS9100D, provides reliable quality and traceable manufacturing with full documentation support.

Why Should You Choose EBest Circuit (Best Technology) as Your Trusted Prototype PCB Board Manufacturer?

EBest Circuit (Best Technology) addresses the most pressing concerns from customers:

- 1. Cost Control: We use smart layout optimization and material grouping to keep costs low. For example, reducing 12-layer stacks into 10-layer HDI structures saved one client 27% of their budget.

- 2. Fast Delivery: Our agile system supports 24â72 hour delivery for urgent projects. We managed a complex auto-driving board in 5 days without cutting corners.

- 3. Technical Adaptability: We support special materials, dense layouts, and rare packages. Our engineers review designs for compatibility and recommend cost-effective tweaks early on.

- 4. Quality Consistency: Our MES system tracks every components. We provide detailed inspection reports, testing logs, and traceability for every batch.

- 5. Support You Can Reach: Our English-speaking engineers are online 24/7. You get real answersânot botsâand fast turnaround on design feedback.

- 6. Customization: We support all major file formats, have no MOQ, and can match complex processes like via-in-pad, impedance control, and mixed-material PCBs.

Weâre not just a prototype PCB board manufacturer. Weâre your project partner. From IoT to medical, from 2-layer FR4 boards to 18-layer hybrid PCBs, we deliver results. Our facilities support PCB manufacturing USA orders and offer overseas support for better flexibility. Customers trust us not just because we build PCBs, but because we provide comprehensive solutions and improve their design and business outcomes.

As a final point, choosing the right prototype PCB board manufacturer can shape your product journey. With EBest Circuit (Best Technology), you reduce costs, cut turnaround time, and gain access to real engineers who care about your project. Whether youâre launching a new wearable, testing EV systems, or creating a next-gen medical tool, we make sure your first prototype is the right one. To start your quote or get a call back from our team, visit our official website or email us at sales@bestpcbs.com.

Tags: Prototype PCB Assembly, Prototype PCB Board Manufacturer