Ethernet routing PCB is the foundation of stable high-speed networks in modern electronics. Whether you’re building routers, industrial controllers, or advanced IoT devices, the design quality directly affects performance. In this blog, we explore the essentials of ethernet routing PCB and how Best Technology helps you overcome the typical design challenges with reliable, fast, and tailored solutions.

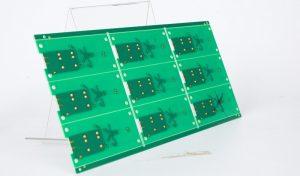

Best Technology is an ethernet routing PCB manufacturer providing high-precision ethernet routing PCB solutions with full support for up to 32-layer stack-ups. Our FR4 PCB range is varied, including single-sided PCB, multi-layer PCB, high Tg PCB, RF PCB, and so on. We are realizing that fast prototyping and one-stop assembly services are instrumental in keeping a competitive edge and winning in international markets. We appreciate the trust you gave us. Your trust is the drive for us to overcome any obstacle and provide more fast prototyping and practical solutions for your projects. Just feel free to let us know your specific ethernet routing PCB requirements via sales@bestpcbs.com.

What is Ethernet Routing PCB?

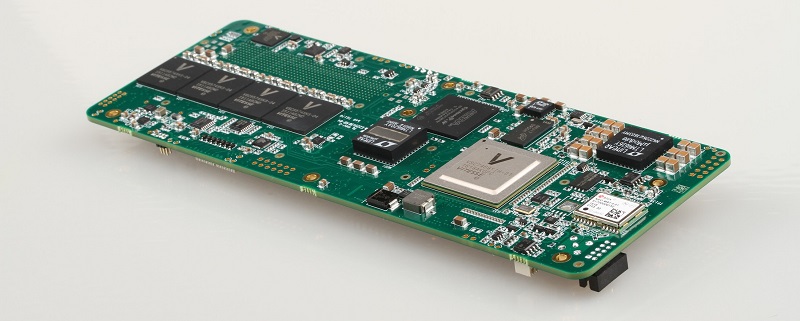

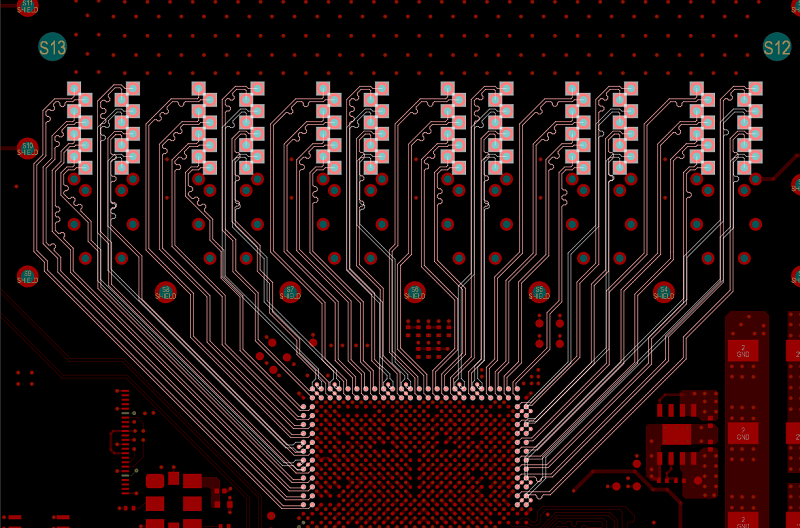

Ethernet routing PCBs are specially designed circuit boards used to manage Ethernet signal paths. These boards handle differential pair routing, impedance matching, and thermal management for high-speed data flow. They must meet tight requirements to ensure stable communication and low interference. With increasing demand for Gigabit Ethernet and 10G+ speeds, the layout needs precision from the start. Best Technology supports all design phases—from prototype to volume production—ensuring consistent quality and signal integrity.

What Are the Three Types of Ethernet?

When designing an Ethernet PCB, it’s helpful to understand the core types:

- 10BASE-T: Basic Ethernet, up to 10 Mbps over twisted pair cable. Easy to route but outdated in many systems.

- 100BASE-T (Fast Ethernet): Up to 100 Mbps, still in use in some industrial and consumer systems.

- 1000BASE-T (Gigabit Ethernet): Up to 1 Gbps and most common today. It needs precise routing to avoid data loss.

Each type demands different impedance control, routing lengths, and connector considerations. Best Technology’s engineering team applies practical guidelines to each level, ensuring your project fits technical and budget goals.

What Is the Primary Purpose of an Ethernet Port on the Motherboard?

The Ethernet port on a motherboard serves as the physical gateway to wired networks. It connects your device to LANs or the internet, allowing stable and secure data exchange. On a PCB, the path from this port must be clean, short, and impedance-matched to maintain high-speed data transfer. We use advanced simulation tools to ensure signal fidelity, reducing EMI and enhancing long-term reliability.

What Is the 3W Rule in PCB Routing?

The 3W rule is a layout technique to minimize crosstalk between adjacent signals. It suggests that the spacing between traces should be at least three times the width of the trace. For Ethernet, which often uses differential pairs, this rule is key to avoiding noise and maintaining clean waveforms. Our PCB layout engineers follow this rule, especially in Gigabit Ethernet sections, and combine it with proper ground shielding and return paths to improve EMC performance.

How to Properly Route an Ethernet PCB?

Proper Ethernet PCB routing means balancing signal quality, EMI reduction, thermal control, and cost. Here’s how:

- Impedance Matching: Use controlled impedance traces for Ethernet pairs. Keep differential pairs tightly coupled and equal in length.

- Minimize Crosstalk: Use the 3W rule and place pairs far enough apart. Avoid sharp bends in traces.

- Grounding: Keep a continuous reference ground. Prevent signal layers from crossing split planes.

- EMC Management: Apply filtering and shielding, especially near connectors and clocks.

- Thermal Management: Add thermal vias, heat sinks, or metal substrates near hot components like PHY chips.

- Cost Control: Optimize layer stackup and use advanced materials only where needed.

Best Technology addresses all of the above through DFM (Design for Manufacturability) checks, ensuring that your design moves to production without delays or surprises. For ethernet routing PCB solution, just feel free to give us a call at +86-755-2909-1601 or send us an e-mail at sales@bestpcbs.com.

How to Solve EMC Interference Issues in Ethernet PCB Layouts?

Ground plane splits and poorly shielded components often create unwanted radiation. Best Technology prevents this by maintaining a uniform ground plane, shrinking power layers, and using ferrite beads or shielding cans around sensitive areas. This helps your design pass EMC testing quickly, saving you costly redesigns and delays.

Gigabit Ethernet devices often use high-power ICs that create local heat. To deal with this, we place heat vias beneath chips, use thermal interface materials, and sometimes recommend metal-backed PCBs. These techniques ensure your board stays cool even under heavy data load. We also provide aluminum substrate options when heat becomes a critical challenge.

Why Choose Best Technology for Ethernet PCB Manufacturing?

- Excellent Layer Count and Material Compatibility. Our production supports up to 32 layers, with high-Tg FR4 and advanced materials like Rogers 4350, Isola 370HR, and Megtron series, offering flexibility for high-speed differential pair routing and EMC shielding design.

- Turnkey Ethernet Routing PCB Solutions. Many customers come to us after facing delays, EMC failures, or thermal issues in early prototypes. We offer the solutions they need: fast, precise, and certified. From layout optimization to advanced testing, we cover all bases. Our engineers also understand how to reduce costs without sacrificing results—making us a trusted partner across industries from telecom to automotive.

- Rapid Prototyping Services. Our team offers fast-turn services, delivering working Ethernet routing PCBs in 5–7 days. We support quick revisions and cost-efficient builds so you can iterate and validate your product fast. That helps reduce time to market and allows real feedback from customers.

- Professional Assembly and Testing. Best Technology uses advanced equipment for SMT and through-hole processes, ensuring that even high-density layouts meet spec. We also perform full functional and AOI testing, X-ray for BGAs, and final verification before shipment. Our services comply with ISO9001, AS9100D, and other key standards.

- Advanced Surface Finishes for High Reliability. Options like ENIG, immersion silver, OSP, and hard gold are available, ensuring excellent surface planarity and oxidation resistance for high-speed Ethernet connector pads.

In summary, designing an Ethernet routing PCB is not just about connecting pins—it’s about performance, reliability, and speed. With Best Technology, you get a partner who understands signal integrity, EMC, thermal control, and cost balance. Our fast prototyping, flexible assembly, and strict quality control help ensure your product succeeds—from the first prototype to mass production. Please feel free to e-mail us directly at sales@bestpcbs.com for a viable solution for Ethernet routing PCB layout.

Tags: Assembly Services, Ethernet Routing PCB, Fast Prototyping