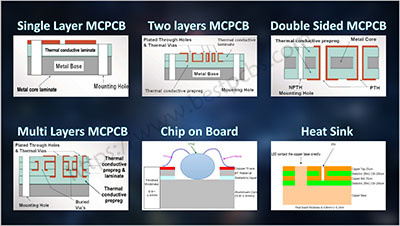

In Best Technology, currently the most common metal used for Metal Core PCB manufacturer are Aluminum, Copper. Today let’s talk about the main differences between aluminum substrate and copper substrate, hoping to help you choose the right substrate in future design projects.

Although they both share similar properties and functions, there are still a few variations between the two kinds of metals. Some of the key differences between aluminium and copper core PCBs are explained in the points below.

1. Thermal Conductivity

The thermal conductivity of copper substrate is up to about 400(W/mK) and the thermal conductivity of aluminum substrate is generally about 200W(W/mK). The thermal conductivity is higher, the transfer efficiency will be better, and the heat dissipation will be better, then the working life will be longer.

2. Electrical Conductivity

Both aluminum and copper, being metals, are electrical conductors of electricity, although the exact degree of this varies between the two metals. When it comes to electrical conductivity, copper has a clear advantage over aluminum. In other words, in applications where there is a need for efficient electrical conductivity, copper makes for an ideal pick.

3. Electrical Resistance

Resistance is very important when it comes to PCB design, as it can have an effect on the overall function and stability of the component. Given that copper has a higher density than aluminum, it tends to have a lower resistance than aluminum, so copper is an better choice where there’s a requirement for thinner circuits and faster electricity transfer.

4. Weight

Since copper has the higher density for per unit area, the weight of copper PCB is much heavier than aluminum PCB for the same design.

In applications where light-weight construction is required more than anything else, aluminum is the preferred material of choice. On the other hand, applications where weight is not much of an issue, tends to be the ones where copper is widely used.

5. Application

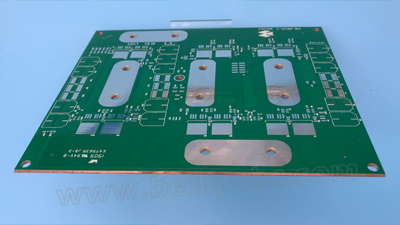

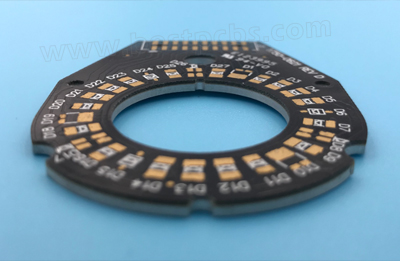

Copper core PCB is the best heat dissipation among all MCPCB, so it’s mostly used in automobile headlights, taillights and some high-tech electronic products (unmanned aircraft, mining machine) high-power lighting equipment. The aluminum core PCB is mostly used in indoor lighting, energy saving lighting, street lighting and other energy-saving lighting electronic products.

In conclusion, due to the above different parameters and performance, the cost of copper is generally more expensive than aluminum. If you have other questions about MCPCB, welcome to contact us .