As we all know if ceramic PCB is very fragile, so it is not easy to do SMT for them.

But we can do the SMT for ceramic PCB easily because we do it every day and we have more than 15 years experiences for doing that.

For the almost SMD components (such as SMD rsistors, capacitors, diode etc), normally we will add the solder paste by using SMT stencil, then put the components by machine, finally do the oven reflow.

For some special components, we will need to solder it by hand, such as through connectors, but it can’t be soldered by hand directly, it need to be put on the heating table to keep the temperature is high enough to make the solder past at melt state. Because the ceramic material with very good heat dissipation, the solder paste will be solidification very easily if don’t put the ceramic PCB on heating table

For some small LED, it can’t be put by SMT machine, because no such small feeder to pick it up, then need to put it on board by hand.

We can do very well for the small BGA components too.

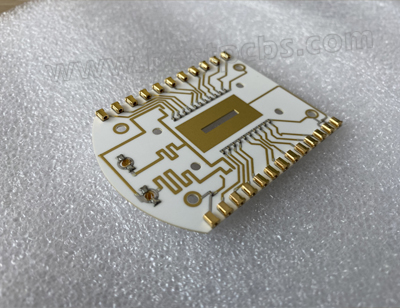

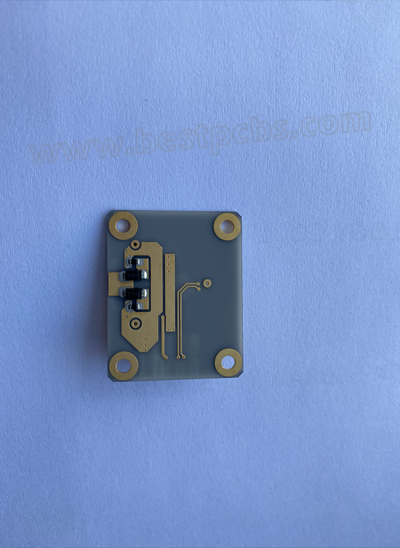

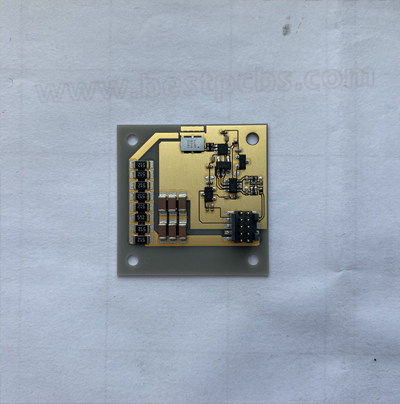

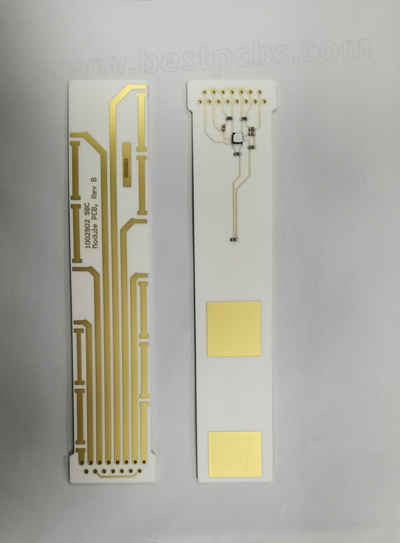

Below some photos of ceramic PCB.

If you would like to know more about ceramic and ceramic PCB SMT, please feel free to email me