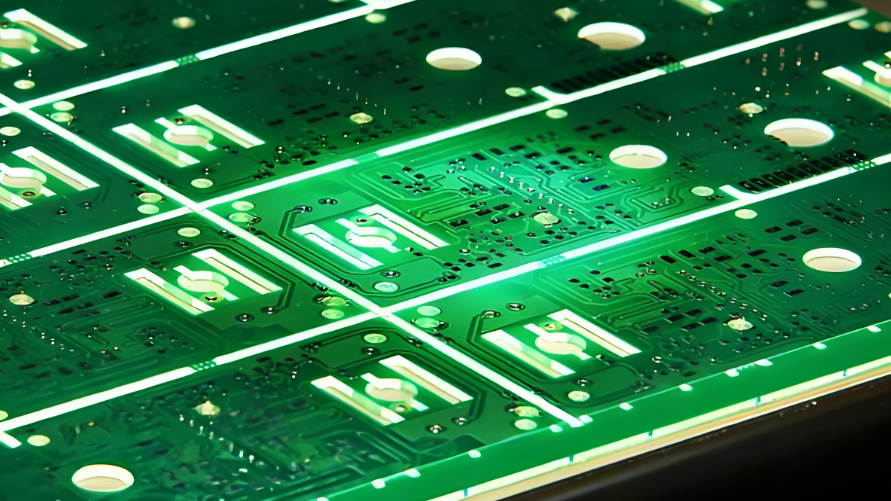

Why Are Most PCBs Green?

Why PCB is green? Most printed circuit boards appear green because of the solder mask, a protective polymer coating applied over copper traces. This layer prevents oxidation, avoids solder bridging during assembly, and improves long-term durability. Historically, manufacturers standardized on green because early solder mask chemistry produced the most stable color in that shade. Over decades, fabrication lines, inspection systems, and operator training all evolved around green boards, reinforcing it as the default option.

Another practical reason is visibility. Green provides balanced contrast between copper pads, silkscreen markings, and components. For engineers reviewing assemblies under microscopes or AOI cameras, this contrast reduces eye fatigue and improves defect detection.

Why Are Most PCBs Green Instead of Red, Blue or Black?

Green solder mask delivers a combination of process stability, inspection clarity, and cost efficiency. Alternative colors exist, but they introduce certain trade-offs:

- Dark colors like black absorb more light, making scratches or solder bridges harder to detect.

- White boards reflect excessive light, which may interfere with automated inspection.

- Bright colors sometimes require extra pigment loading, which slightly complicates coating uniformity.

Because fabrication lines have optimized exposure parameters, curing temperatures, and AOI algorithms around green, it remains the safest production choice for high-volume manufacturing.

What Is the Green Part of a Circuit Board Made Of?

The green layer is typically an epoxy-based liquid photoimageable (LPI) solder mask. It consists of:

- Epoxy resin matrix

- Photoinitiators for UV curing

- Pigments that produce the green coloration

- Fillers for mechanical strength and thermal stability

During fabrication, the mask is applied as a liquid coating, exposed through artwork, and then chemically developed to reveal pads. The resulting film protects copper traces from contamination while maintaining insulation between conductors.

Does Green PCB Color Improve Electrical Performance or Reliability?

Color alone does not alter impedance, signal speed, or electrical conductivity. Those characteristics depend on stackup design, copper geometry, and dielectric materials.

However, green boards often appear more reliable because:

- Stable processing reduces solder mask defects

- Easier inspection improves yield rates

- Mature chemistry lowers variation between batches

In practice, reliability benefits come from manufacturing consistency rather than color physics.

Why Do Engineers Prefer Green PCB for AOI and Inspection Accuracy?

Automated Optical Inspection systems rely on controlled lighting and contrast recognition. Green solder mask reflects light in a balanced spectrum that helps cameras differentiate between pads, traces, and silkscreen markings.

Benefits for inspection include:

- Reduced glare compared to white surfaces

- Higher edge contrast than dark colors

- Stable color recognition for machine vision algorithms

Human operators also find green less visually exhausting during long inspection sessions, which further improves quality control.

Is Green PCB Cheaper Than Other PCB Colors in Mass Production?

Yes ÔÇö in most cases. The price difference comes from process optimization rather than pigment cost.

Why green often costs less:

- High demand lowers material procurement costs

- Default exposure and curing settings reduce setup time

- Fewer inspection challenges lower yield risk

For large production runs, alternative colors may only increase cost slightly, but for prototypes the difference can be noticeable.

Why Did Green Become the Industry Standard Historically?

Early PCB manufacturing in the 1970s and 1980s used epoxy-based solder masks that naturally appeared green due to pigment chemistry. At the time:

- Green dyes provided the best UV stability.

- Alternative pigments were less resistant to heat and solvents.

- Military and industrial standards documented green as the reference color.

Once assembly houses invested in equipment calibrated for green boards, the ecosystem reinforced itself. Even today, many legacy production lines maintain settings optimized for that traditional color.

When Should You Choose Black, White or Blue PCB?

Modern fabrication supports many solder mask colors. Each serves different purposes:

- Black PCB ÔÇö popular for consumer electronics aesthetics or stealth designs.

- White PCB ÔÇö often used in LED lighting to improve light reflection.

- Blue PCB ÔÇö chosen for branding or prototype differentiation.

- Red PCB ÔÇö common in development kits and educational hardware.

Color selection should be based on inspection needs, thermal considerations, and product appearance rather than performance myths.

Green PCB vs Black PCB ÔÇö Which One Is Better for High-Density Designs?

High-density interconnect (HDI) designs demand precise inspection and minimal defects. Green boards usually provide clearer contrast for microvias, fine-pitch components, and solder joints.

Black PCBs can look visually premium, but they present challenges:

- Lower visibility for hairline scratches

- Harder optical inspection

- Increased glare under certain lighting angles

For extremely dense layouts, many engineering teams still favor green for manufacturing reliability.

Does PCB Color Affect Heat Dissipation or Thermal Performance?

Color itself has minimal influence on thermal conductivity. Heat transfer is governed by:

- Copper thickness

- Thermal vias

- Substrate material (FR-4, aluminum, ceramic, etc.)

Dark colors may absorb more radiant heat in open environments, but inside electronic assemblies this effect is negligible compared with structural design choices.

Why Do Many Prototype PCBs Still Default to Green Color Today?

Prototype fabrication emphasizes speed and predictability. Green boards allow manufacturers to:

- Use default process parameters without additional setup

- Maintain fast turnaround times

- Reduce risk during early design validation

Because engineering teams often prioritize quick iteration, green remains the standard option for prototypes.

Are Custom Color PCBs More Expensive or Harder to Manufacture?

Custom colors are generally feasible, but several factors may affect cost:

- Extra quality checks to ensure color uniformity

- Slightly different curing behavior depending on pigment type

- Potentially longer lead times for non-standard materials

In high volumes, price differences become smaller, but for quick-turn orders, green usually stays the most economical choice.

FAQs

Does green solder mask mean a PCB is higher quality?

Not necessarily. Quality depends on fabrication control, materials, and design rules rather than color.

Can I mix PCB colors within one project?

Yes. Some designers use different colors to identify board revisions or functional modules during testing.

Is black PCB more conductive or faster?

No. Electrical performance is determined by copper geometry and dielectric properties, not by solder mask color.

Why do some premium consumer devices use black boards?

Mainly for aesthetics and branding. Engineering teams often accept inspection trade-offs to achieve a distinctive visual style.