Need fast PCB prototyping solutions? Fast PCB Prototyping enables quick hardware testing through rapid manufacturing, requiring careful vendor choice, thermal optimization, signal testing, and quality checks to ensure 24-hour delivery with reliable performance.

Best Technology stands out as a premier fast PCB prototype manufacturer by delivering industry-leading 24-hour turnaround times without compromising quality. Our automated smart factories equipped with advanced 6-layer simultaneous drilling technology and high-speed automated SMT production lines enable rapid prototyping cycles that are 40% faster than industry standards. We maintain this speed while achieving 99.8% first-pass yield through precision SMT placement systems and real-time thermal monitoring. For mission-critical projects, our express service guarantees functional prototypes within 24 hours, supported by 24/7 engineering support and live production tracking. Clients benefit from our decade of expertise in high-speed digital and RF designs, with specialized solutions for HDI, flex-rigid, and high-frequency boards up to 77GHz. Our ISO 9001-certified quality system combines automated optical inspection (AOI), flying probe testing, and signal integrity verification to ensure reliability at accelerated production speeds. The integration of cutting-edge SMT assembly infrastructure, optimized logistics networks, and dedicated quick-turn production lines makes us the preferred partner for startups requiring rapid iteration capabilities. Welcome to contact us: sales@bestpcbs.com.

What Is Fast PCB Prototyping?

Fast PCB Prototyping is the process of rapidly manufacturing functional printed circuit board samples for testing and validation before mass production. It enables hardware developers to quickly verify designs, identify potential issues, and accelerate product development cycles. Leading Fast PCB Prototype Manufacturers specialize in delivering high-quality prototypes within 24-72 hours using advanced manufacturing techniques and strict quality control. This service is particularly valuable for international trade clients who need to maintain competitive timelines while ensuring reliability. By partnering with trusted fast PCB prototyping providers, businesses can reduce development costs, speed up market entry, and minimize risks in electronics manufacturing.

What Are Benefits of Fast PCB Prototyping?

Benefits of fast PCB prototyping:

- Speed to Marketā ā Fast PCB Prototyping cuts waiting time from weeks to 1-3 days, helping global clients meet tight deadlines and stay ahead of competitors.

- Cost Savingsā ā Early design validation through fast PCB prototyping prevents expensive rework in mass production, reducing overall project costs.

- Risk Reductionā ā Leading fast PCB prototype manufacturers test functionality before full-scale production, minimizing defects and supply chain delays.

- Flexible Iterationsā ā Quick turnaround allows multiple design revisions, ensuring optimal performance before finalizing orders.

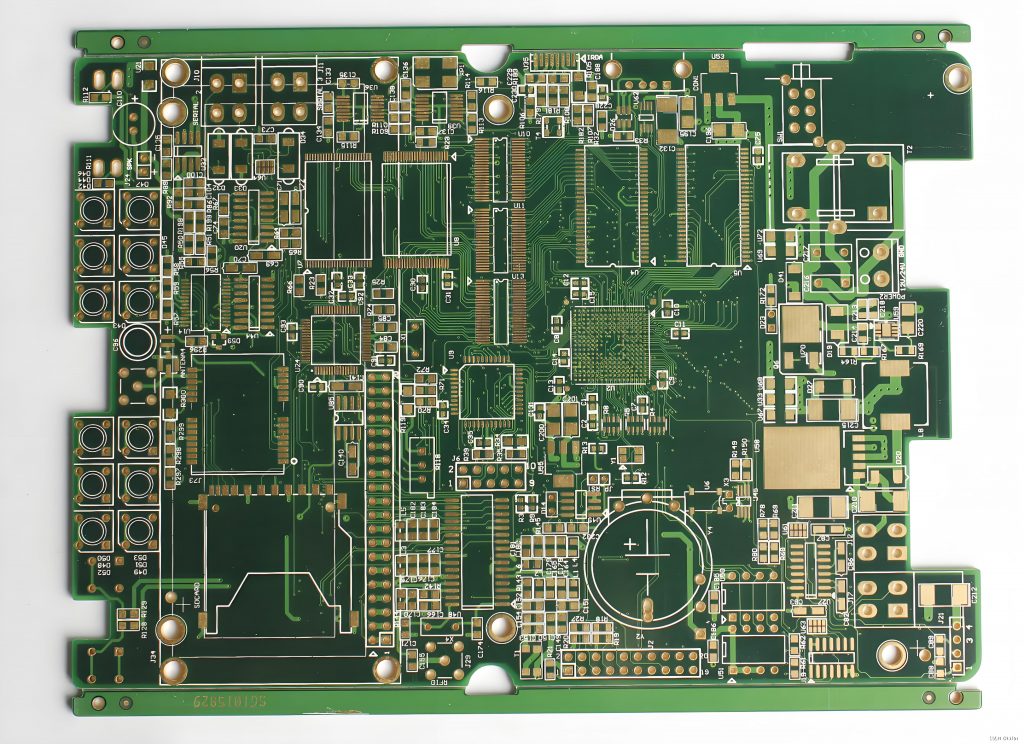

- Quality Assuranceā ā Reputable manufacturers use advanced equipment (e.g., 6-layer HDI) and ISO-certified processes for reliable prototypes.

- Global Logistics Supportā ā Many fast PCB prototype manufacturers offer DHL/FedEx shipping, ensuring timely delivery for overseas clients.

- Scalabilityā ā Seamless transition from prototypes to bulk production with the same supplier avoids compatibility issues.

- Technical Collaborationā ā Expert engineers from top manufacturers provide design feedback to enhance product durability and efficiency.

What Are Applications of Fast PCB Prototyping?

Application of Fast PCB prototyping:

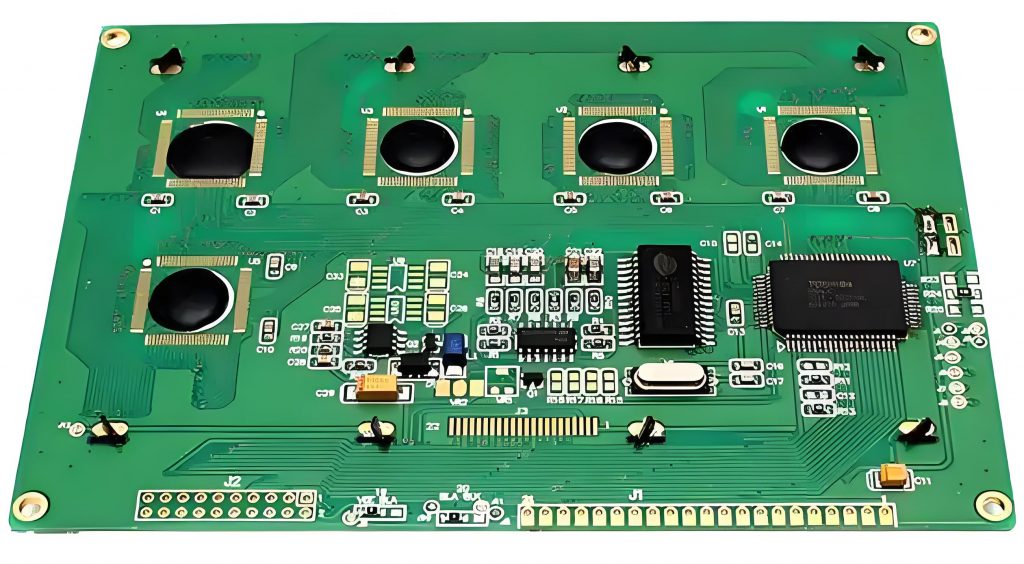

Consumer Electronics Accelerationā

- Smartphone motherboard prototypes (10-16 layers) for 5G antenna array testing within 72 hours.

- Wearable device flexible circuits (0.1-0.3mm thickness) with 3-day iterative cycles.

- VR headset PCBs for thermal dissipation validation using 2oz copper prototypes.

Automotive Electronics Validationā

- EV battery management systems (6-8 layer prototypes) for crash simulation in 5 working days.

- Autonomous vehicle radar modules (77GHz RF boards) with impedance control (Ā±3%).

- Dashboard display rigid-flex boards tested under -40Ā°C to 105Ā°C temperature cycles.

Medical Device Complianceā

- Portable ECG monitors with medical-grade FR4 material certification in 48 hours.

- Implantable device prototypes featuring biocompatible gold plating (0.05Ī¼m).

- Surgical robot PCBs with 20Ī¼m laser micro-vias for high-density interconnects.

Industrial Automation Solutionsā

- Motor drive controllers (10oz heavy copper) for vibration testing within 96 hours.

- PLC interface cards with 0.15mm trace/space for harsh environment validation.

- Machine vision camera boards supporting 10Gbps data transmission testing.

Aerospace & Defense Systemsā

- Satellite communication boards (RT/duroid 5880 material) for space environment simulation.

- Avionics prototypes undergoing 6-week accelerated aging tests equivalent to 5 years.

- UAV flight controllers with conformal coating options for moisture resistance.

Telecommunications Infrastructureā

- 5G mm Wave antenna arrays (32-layer stack-ups) for signal integrity analysis.

- Optical network equipment with ā¤1dB insertion loss prototypes.

- Base station power modules supporting 1000W/cmĀ² thermal stress tests.

How to Choose Fast PCB Prototype Manufacturers?

Below are tips about how to choose fast PCB prototype manufacturer:

Technical Expertise

- Look for manufacturers with HDI, flex-rigid, and RF/microwave PCB prototyping experience.

- A U.S. client chose a partner with LDI technology to achieve 25Ī¼m traces for a wearable EEG device.

Certifications

- Must-Haves include ISO 9001, ISO 13485, AS9100, and UL 94V-0.

- Ensure compliance with EUās RoHS/REACH, Chinaās CQC, and Japanās PSE.

Turnaround Time

- Aim for 24ā72 hours for 2-layer PCBs, 5ā7 days for 8+ layers.

- Avoid factories promising ā24-hour turnaroundā without clarifying complexity limits.

Material Inventory

- Check if they stock high-TG FR4, Rogers 4350B, and IMS for immediate use.

- A German firm lost 2 weeks when a manufacturer had to import PTFE for a 5G antenna prototype.

DFM Support

- Top manufacturers offer free DFM reviews to catch issues like trace spacing violations.

- A Canadian startup reduced rework by 60% after a DFM audit flagged solder mask alignment errors.

Quality Control

- Look for AOI, X-ray for BGAs, and TDR for impedance control.

- Ask for ITAF 16949 or IPC-6012 Class 3 compliance.

Cost Transparency

- Request a breakdown for setup, engineering, and NRE fees.

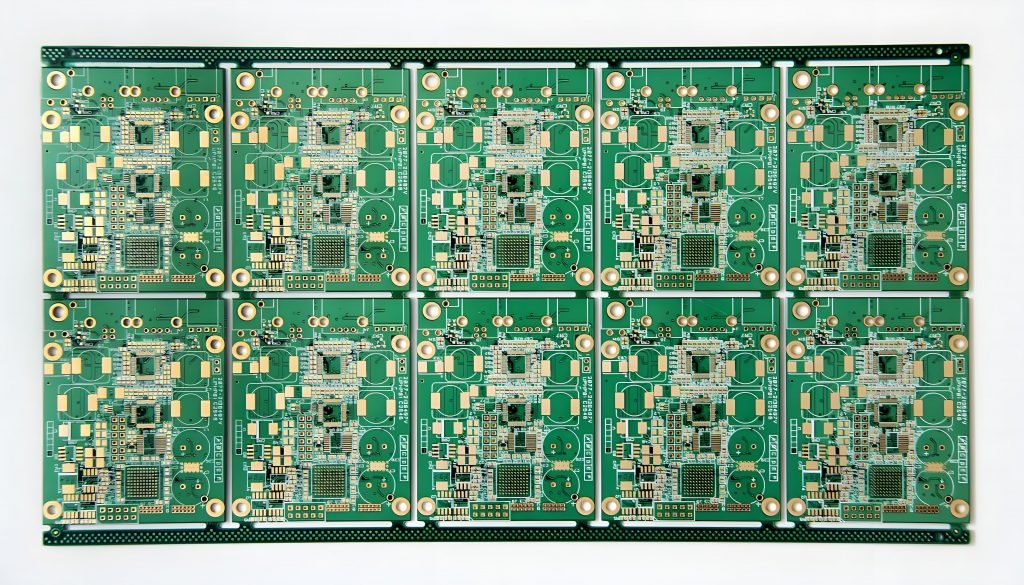

Scalability

- Ensure the factory handles both 5-piece prototypes and 100K-unit runs.

- A Japanese EV firm cut lead times by 40% by using the same partner for BMS prototypes and mass production.

Communication & Support

- Choose partners with English/Spanish/Mandarin-speaking engineers.

- Look for cloud portals with Gerber viewers, order tracking, and instant chat.

Customer Reviews & Case Studies

- Check platforms like Trustpilot or LinkedIn for reviews from foreign clients.

- Avoid factories with multiple complaints about missed deadlines or quality lapses.

How to Optimize Thermal Management Fast PCB Prototype Design?

Below are strategies to optimize thermal management fast PCB prototype design:

Material Selection for Thermal Conductivity

- Base Materials: Use high-Tg FR-4 (ā„170Ā°C) or ceramic-filled laminates (e.g., Rogers TMM) for improved heat dissipation.

- Copper Weight: Opt for 2oz+ copper thickness to reduce resistance and lower Joule heating.

Component Placement Optimization

- Thermal Zoning: Isolate heat-generating components (e.g., MOSFETs, FPGAs) from temperature-sensitive parts (e.g., oscillators, ADCs).

- Airflow Alignment: Orient heat sinks and fans parallel to natural convection currents.

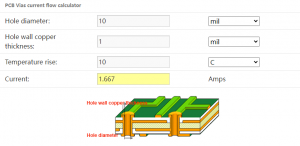

Thermal Via Arrays

- Design: Deploy 0.3mm-diameter vias in 5×5 grids under hot components to conduct heat to inner layers or ground planes.

- Spacing: Maintain ā¤1mm pitch between vias for optimal thermal conductivity.

Embedded Heat Spreaders

- Integration: Embed copper or aluminum plates (1ā2mm thick) within the PCB stack-up for direct heat sinking.

- Example: Reduced junction temperature by 15Ā°C in a 100W LED driver prototype.

Plane Resistance Minimization

- Layer Stackup: Allocate dedicated power/ground planes adjacent to heat-generating layers.

- Thickness: Use 2oz copper for power planes to lower DC resistance (<2mĪ©/sq).

Thermal Interface Materials (TIMs)

- Selection: Apply phase-change materials (e.g., 3W/mK) or graphite sheets for low-thermal-impedance interfaces.

- Application: Use stencils to ensure 100ĀµmĀ±10Āµm thickness consistency.

Forced Convection Integration

- Fan Placement: Position blowers near high-power components with static pressure ratings matching enclosure airflow resistance.

- Ventilation: Include 8mm+ diameter holes in PCB cutouts for unobstructed airflow.

Monte Carlo Thermal Simulation

- Tool: Use ANSYS Icepak or SimScale to model transient temperature rise under worst-case loads.

- Validation: Compare simulations with IR camera measurements (e.g., FLIR E76) post-assembly.

Dynamic Power Management

- Firmware: Implement thermal throttling in microcontrollers to reduce clock speeds by 20ā40% at Tj > 105Ā°C.

- Sensors: Integrate NTC thermistors near hotspots for real-time monitoring.

Post-Production Thermal Cycling

- Stress Test: Subject prototypes to 100+ cycles (-40Ā°C to +125Ā°C) to identify solder joint fatigue.

- Rework: Use hot air rework stations (e.g., 480Ā°C nozzle) for localized BGA reflow without delamination.

How to Achieve Fast PCB Prototyping Within 24 Hours?

Below are 10 practical steps to accelerate turnaround times without compromising quality:

1. Design Simplification

- Layer Reduction: Limit to 2ā4 layers for faster etching and drilling.

- Standard Footprints: Use pre-verified component libraries to avoid DFM rework.

2. Automated DFM Checks

- Tool: Integrate KiCad DRC or Altium Design Rules to flag errors like trace spacing violations or missing solder mask layers.

- Example: A 30-minute DFM audit reduced rework by 50% in a 4-layer PCB prototype.

3. Material Pre-staging

- Stockpile: Maintain inventory of common substrates (e.g., FR-4 1.6mm, 1oz copper) and stencils for SMT assembly.

- Pre-Cut Panels: Use 18×24-inch panels to minimize waste and speed up CNC routing.

4. Parallel Manufacturing

- Simultaneous Operations:

- Layer 1: Etching + drilling.

- Layer 2: Solder mask application.

- Layer 3: Surface finish (e.g., ENIG).

- Tool: Use multi-spindle CNC machines to drill 1,000+ holes/minute.

5. High-Speed SMT Assembly

- Pick-and-Place: Deploy 8-head SMT machines with 15,000 CPH (Components Per Hour) throughput.

- Reflow Optimization: Use nitrogen-inerted ovens for 3-minute lead-free soldering cycles.

6. Skip-Lot Testing

- Sampling: Test 1 board from every 10-unit batch for impedance/SI, assuming consistent process controls.

- Risk Mitigation: Reserve 100% testing for mission-critical designs (e.g., medical, aerospace).

7. Express Logistics

- Local Couriers: Partner with same-day delivery services for component sourcing within a 50-mile radius.

- Air Freight: Use priority shipping for out-of-stock items (e.g., Rogers 4350B laminates).

8. Real-Time Production Tracking

- Dashboard: Implement IoT sensors to monitor etching baths, oven temperatures, and SMT head pressures.

- Alerts: Receive SMS/email notifications for deviations (e.g., reflow oven exceeding 245Ā°C).

9. 24/7 Engineering Support

- On-Call Team: Rotate shifts to handle design queries, DFM reviews, and test failures.

- Live Chat: Use tools like Slack or Microsoft Teams for instant communication.

10. Pre-Certification Preparation

- Documentation: Pre-fill FCC/CE test reports using simulated data to expedite compliance.

- Labeling: Print UL marks and RoHS symbols during solder mask application.

How to Ensure Quality of Fast PCB Prototype Manufacturing?

Below are steps to guarantee reliability, compliance, and performance:

Design for Manufacturability (DFM) Reviews

- Proactive Checks: Use professional EDA tools (e.g., Altium, Cadence) to validate designs for line width/spacing, impedance control, and drill hole ratios.

- Example: A U.S. client reduced rework by 40% after a DFM audit flagged improper solder mask clearance on a 12-layer PCB.

Material Certification & Traceability

- Supplier Audits: Require ISO 9001/IATF 16949-certified suppliers for base materials (e.g., FR-4, Rogers 4350B) and track batch consistency via COAs (Certificates of Analysis).

- Red Flag: Avoid suppliers lacking UL 94V-0 or RoHS compliance documentation.

Advanced Process Control

- Critical Parameters: Monitor etching time/temperature (Ā±2Ā°C accuracy), laser drilling precision (ā¤25Ī¼m tolerance), and copper plating thickness (1ā2oz standard).

- Tool: Implement SPC (Statistical Process Control) to detect deviations in real time.

Automated Optical Inspection (AOI)

- Defect Detection: Use AOI to identify solder bridges, missing pads, or over-etching with 99.95% accuracy.

- Integration: Pair with ICT (In-Circuit Testing) for comprehensive electrical validation.

X-ray Inspection for Hidden Defects

- BGA/QFN Analysis: Deploy X-ray to detect voids, misalignments, or insufficient solder in ball grid arrays.

- Case Study: A Japanese firm avoided a 15% failure rate in automotive ECUs by catching cold solder joints via X-ray.

Environmental Stress Testing

- Thermal Cycling: Subject prototypes to -55Ā°C to +125Ā°C cycles (1,000+ cycles for automotive/aerospace grade).

- Humidity Resistance: Test at 85Ā°C/85% RH for 168 hours to simulate tropical conditions.

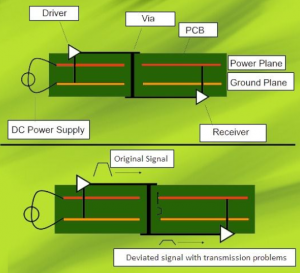

Signal Integrity Verification

- TDR/TDT Testing: Validate impedance control (Ā±5% tolerance) and crosstalk mitigation on high-speed designs (e.g., 10Gbps+).

- Tool: Use Keysight E5071C or similar analyzers for precise measurements.

Supplier Collaboration & Audits

- Qualification: Prioritize manufacturers with IPC-6012 Class 3, AS9100, or ISO 13485 certifications.

- On-Site Audits: Inspect facilities for ESD control (ā¤100V static discharge) and 5S compliance.

First Article Inspection (FAI)

- Documentation: Require FAI reports detailing layer stack-up, via plating thickness, and surface finish (e.g., ENIG, OSP).

- Example: A German client rejected a batch due to 0.5mm deviation in impedance vs. 50Ī© specified in the FAI.

Post-Production Analytics

- Failure Analysis: Use SEM (Scanning Electron Microscopy) for root-cause diagnosis of delamination or micro-cracks.

- Data-Driven Adjustments: Apply machine learning to predict and prevent recurring defects.

How to Test Signal Integrity of Fast Turn Prototype PCB Board?

Testing signal integrity (SI) in fast-turn PCB prototypes is critical to ensure high-speed designs meet performance targets. Below are 10 detailed, actionable steps to validate SI, combining advanced tools, industry standards, and real-world examples:

1. Pre-Test Design Review

- Validate Specifications: Confirm impedance requirements (e.g., 50Ī© for USB 3.2, 100Ī© for PCIe), transmission line lengths (ā¤5cm for 28Gbps signals), and differential pair coupling (ā„3W rule).

- Simulation: Use tools like Hyper Lynx to simulate reflections, crosstalk, and attenuation before prototyping.

- Example: A U.S. client identified a 12% impedance mismatch in a 16-layer PCB by simulating layer transitions pre-production.

2. Time Domain Reflectometry (TDR) Testing

Tool: Use a Tektronix TDR/TDT Analyzer to measure impedance continuity.

Process:

- Probe critical nets (e.g., DDR5 DQ lines, HDMI traces).

- Check for discontinuities like via stubs, neck-downs, or solder mask bridges.

Threshold: Target Ā±5% impedance tolerance (e.g., 47.5ā52.5Ī© for 50Ī© trace).

3. Eye Diagram Analysis

- Tool: Generate eye diagrams using a Keysight DSOX1204G Oscilloscope and BERT (Bit Error Rate Tester).

- Metrics:

- Eye Height: ā„600mV for 5Gbps signals.

- Eye Width: ā„0.4 UI (Unit Interval) for low jitter.

- Case Study: A Japanese firm reduced eye closure by 30% by optimizing pre-emphasis in a 10Gbps SERDES link.

4. Crosstalk Measurement

Test Setup: Inject a 1GHz sine wave into aggressor traces while monitoring victim traces.

Limits:

- Near-End Crosstalk (NEXT): ā¤3% of aggressor signal.

- Far-End Crosstalk (FEXT): ā¤1.5% for 28Gbps+ signals.

Mitigation: Increase spacing to ā„3x trace width or use grounded guard traces.

5. Insertion Loss (S21) & Return Loss (S11) Testing

Tool: Use a Vector Network Analyzer (VNA) (e.g., Copper Mountain Technologies M5065).

Thresholds:

- Insertion Loss: <-3dB at Nyquist frequency (e.g., <14GHz for 28Gbps PAM4).

- Return Loss: <-20dB at target frequencies.

Red Flag: A German client rejected a PCB batch due to -8dB insertion loss at 12GHz, traced to poor FR-4 material selection.

6. Power Integrity Co-Testing

PDN (Power Delivery Network) Analysis:

- Measure DC IR drop (<2% of nominal voltage) using a Keysight N6705C Power Analyzer.

- Check AC impedance (<10mĪ© at 100kHzā1MHz) with a Picotest J2120A Injector.

Example: A Canadian startup reduced voltage ripple by 40% by adding decoupling capacitors near a 12V-to-1.8V LDO.

7. Thermal Stress Testing

Process:

- Subject PCB to 1,000 thermal cycles (-55Ā°C to +125Ā°C).

- Monitor SI degradation using TDR/eye diagrams post-cycling.

Impact: A Japanese automotive client found a 15% increase in insertion loss in a PCB lacking ENIG finish after thermal shock.

8. Automated SI Validation

- Tools: Use LabVIEW or Python scripts to automate TDR sweeps and eye diagram captures.

- Benefit: Reduce testing time by 60% and eliminate manual errors.

- Integration: Pair with JTAG Boundary Scan for concurrent functional testing.

9. Compliance Verification

- Standards: Ensure compliance with:

- IPC-6012: For impedance control and via reliability.

- IEEE 802.3: For Ethernet PHY performance.

- USB-IF: For USB 4.0 Gen 3Ć2 (20Gbps) compliance.

- Certification: Use authorized labs like Granite River Labs (GRL) for final validation.

10. Iterative Design Optimization

- Debug Workflow:

- Isolate failing nets using near-field probes.

- Adjust trace length matching (ā¤10mil skew for DDR5) or replace materials.

- Case Study: A U.S. client resolved 20% eye closure in a 400Gbps QSFP-DD module by optimizing back drilling depth.

Conclusion

In conclusion, fast PCB prototyping accelerates product launches, reduces costs, and ensures global compliance. From consumer electronics to aerospace, its applications drive innovation. Choose Best Technology for 24-hour turnaround, ISO-certified quality, and advanced SI/thermal management. Expert in HDI, flex-rigid, and RF/microwave PCBs, we guarantee performance. Contact Best Technology now for a quote and elevate your prototyping efficiency: sales@bestpcbs.com.

Tags: Fast PCB Prototype Manufacturers, Fast PCB Prototyping