PCB assembly and soldering services are crucial for turning your circuit designs into working electronic products. Whether you need prototypes or high-volume production, choosing the right service partner matters. In this article, we will walk you through key aspects of PCB assembly and explain why Best Technology can be the right partner for your projects.

Best Technology provides fast PCB assembly and soldering services with great quality in the marketplace. Founded in 2015, our SMT factory handles SMT placement, post-soldering, testing, and packaging. Our facility includes separate SMT placement and post-soldering workshops to ensure process control. Our competitive advantage lies in fast PCB assembly and soldering services, enabling rapid prototyping, and high-quality PCBA. For specific technical questions and inquiries, please email us from our Contact Us page on the website. We are happy to provide you with a quote once receiving your BOM list, silk screen position diagram, and SMD Coordinates. Â

What Are PCB Assembly and Soldering Services?

PCB assembly and soldering services refer to the process of placing and soldering electronic components onto printed circuit boards. It includes everything from sourcing materials to final quality checks. Some services handle the entire workflowâthis is called turnkey PCB assembly. Others might only handle part of the process. Quality and speed are two main expectations when customers look for these services.

How to Solder Components to a PCB?

Soldering starts by applying solder paste onto the boardâs pads. Next, components are placed, usually by automated pick-and-place machines. After that, the board goes through a reflow oven where the solder melts and connects the parts. For through-hole parts, wave or hand soldering is used. Accuracy and control are key here to avoid cold joints, bridges, or misalignment. At Best Technology, we optimize every parameterâtemperature, speed, and timingâfor reliable soldering results.

Can Soldering Damage PCB?

Yes, improper soldering can damage PCBs. Overheating, incorrect solder settings, or poor materials may lead to issues like delamination, pad lift, or cracks. However, with the right setup and trained staff, such risks are minimal. Best Technology uses controlled environments and strict handling procedures to protect your boards. Our stable supply chain ensures high-quality solder and paste, avoiding quality dips.

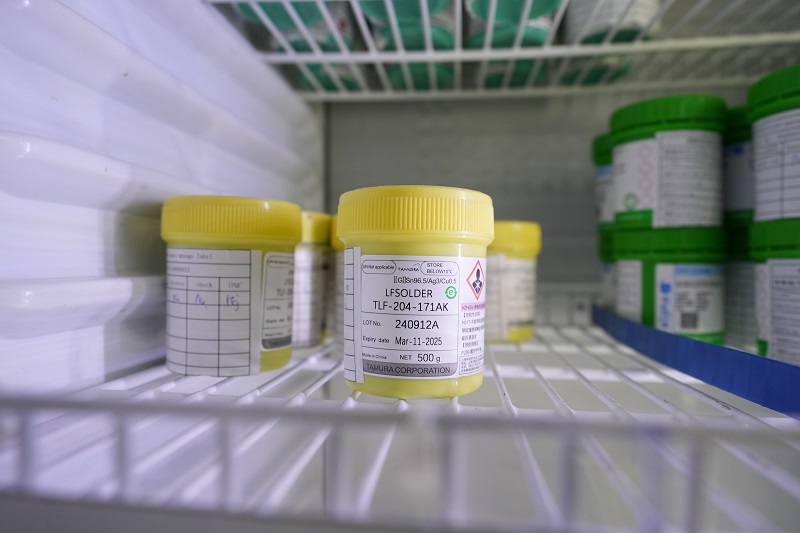

How Long Can Solder Paste Sit Before Reflow?

Solder paste typically lasts between 4 to 24 hours, depending on the environment and type of paste. If exposed too long, it may dry out or absorb moisture. This can lead to poor solder joints. Best Technology stores solder paste under strict conditions and tracks usage carefully to avoid issues. Weâve implemented moisture control protocols to improve product stability.

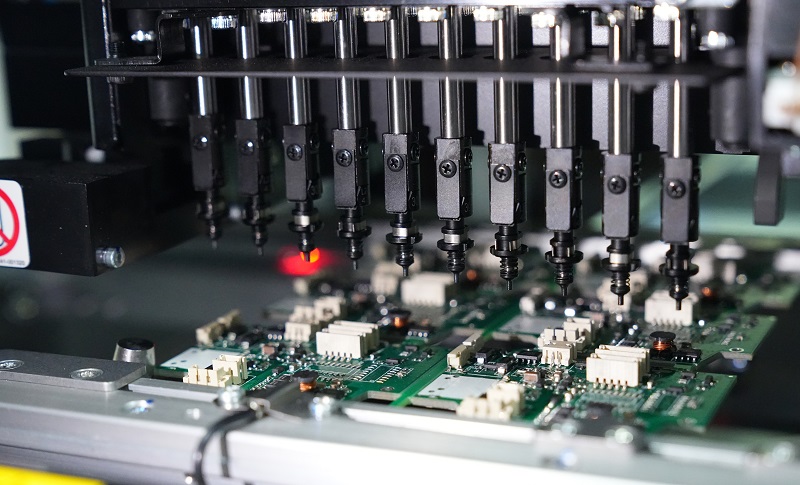

What Is the SMT Process of PCB?

The SMT (Surface Mount Technology) process in PCB assembly involves several tightly controlled steps to ensure high accuracy and quality. Hereâs how Best Technology carries it out:

- Incoming Material Check:Â We inspect BGA, PCB, and all components before production starts.

- Pre-Baking:Â Moisture-sensitive parts and PCBs go through a baking process to remove any trapped moisture.

- Solder Paste Application:Â Solder paste is applied to the board using a stencil printer.

- Printing Inspection (SPI):Â A 3D SPI machine checks solder paste volume and alignment.

- Pick-and-Place:Â SMT machines place components precisely onto the solder paste.

- Reflow Soldering:Â Boards enter a reflow oven where controlled heat melts the paste and forms solder joints.

- Cleaning and Tail-End Inspection:Â After reflow, we check for visible defects.

- Post-Reflow Inspection:Â AOI machines verify component placement, polarity, and solder quality.

- X-Ray (if BGA is used):Â X-ray inspection is done to check BGA and other hidden solder joints.

- Through-Hole Soldering:Â Manual or wave soldering is done for any THT components.

- Cleaning:Â Flux residue is removed to prevent corrosion or electrical leakage.

- Programming and Testing:Â Firmware is flashed, and functional testing is conducted.

- Conformal Coating:Â Protective film is applied if needed to resist moisture and dust.

- Potting and Glue:Â Epoxy or silicone may be added for mechanical protection.

- Final Assembly:Â Assembled boards are integrated into their housings or modules.

- Labeling:Â Barcodes and tracking labels are attached.

- Depaneling:Â Boards are separated if they were processed in panel form.

- Shipping Preparation:Â Products are packed using ESD-safe bags, blade cards, bubble wrap, or blister trays.

In summary, the SMT (Surface Mount Technology) process includes stencil printing, pick-and-place, reflow soldering, and inspection. Itâs efficient, fast, and widely used in modern electronics. SMT helps reduce size, weight, and cost. Our lines run 24/7 using high-speed machinery. We regularly check nozzle alignment and paste deposition to avoid any solder defects. Real-time inspection ensures consistency and helps catch early faults. This complete process ensures high-quality boards that are ready for your final application. Each step is tracked and controlled, which helps us deliver consistent and reliable results.

How Long Does PCB Assembly Take?

Lead time varies by project size and complexity. Quick-turn prototyping can take 1â3 days. Mass production may need a week or more. At Best Technology, we optimize production schedules to meet tight deadlines. Even with sudden design changes or material shortages, our supply network helps us adjust quickly. We offer flexible batch runs and fast rework options, reducing your waiting time.

How Much Does It Cost to Assemble a PCB?

The cost depends on board size, component count, soldering type, and testing needs. Prototype builds are more costly per piece but help save in the long run. Frequent changes can drive up labor costs. At Best Technology, we support customers with transparent quotes. Our modular design approach helps reduce unnecessary complexity and costs. Using the right partner avoids hidden charges and poor sourcing decisions.

Why Choose Best Technology for Your PCB Assembly & Soldering Needs?

Best Technology stands out with fast delivery, strict quality control, and responsive support. Our team handles your project from sourcing to final inspection with attention to detail. Hereâs why many global companies choose us:

- Quick Turnaround:Â We streamline scheduling and integrate automated lines. This ensures your boards are delivered on timeâeven under pressure.

- Superior Quality:Â From soldering parameters to cleanroom environments, we leave nothing to chance. Our team helps reduce human errors by giving early DFM feedback. This lowers risk and makes your launch smoother. And with complete testingâincluding X-RAY, AOI, ICT, and IC programmingâand full box build capability for both metal and plastic housings, we deliver end-to-end assembly solutions with consistent quality. Our defect rate remains far below industry average.

- Real Technical Support:Â We donât keep you waiting. Our engineers answer fastâday or night. Youâll never be left in the dark during production.

- âPrecision SMT Capability: Our SMT process handles fine-pitch components down to 0.2mm BGA and 0.25mm connectors with high precision, ensuring reliable soldering even on dense boards.

- âFlexible SMT PCB Size: We support a wide PCB size range from 50Ă50mm up to 1200Ă360mm, covering everything from compact modules to large industrial panels.

Our key strengths include rapid prototyping, 24/7 tech support, high SMT precision, and flexible production. Please contact us directly via sales@bestpcbs.com for more information on our SMT Assembly Capability.

To conclude, great PCB assembly and soldering services are more than fast delivery. Theyâre about reliability, attention to detail, and responsive support. At Best Technology, we bring all of these to your table. You get expert handling, tight quality control, and flexible serviceâfrom prototype to volume production. Thatâs why 1700 customers across 40 countries give us good reviews. If you’d like to visit our SMT factory, please email us at sales@bestpcbs.com and we will take care of it immediately.

Tags: Fast PCB Assembly and Soldering Services with Great Quality