Active metal brazing (AMB) has become a cornerstone technology for bonding ceramics to metals in high-demand industries. From power electronics and aerospace to automotive applications, this process delivers strong, hermetic joints that conventional methods can’t match. Unlike typical soldering or standard brazing, AMB uses filler alloys containing active elements that directly react with ceramics, creating a chemical bond rather than relying only on mechanical adhesion.

As design engineers pursue lighter, stronger, and more thermally stable components, active metal brazing substrate technology offers unmatched reliability. Let’s explore how this process works, what materials are commonly used, and the recent advances that continue to refine its performance.

What Is Active Metal Brazing (AMB) and How Does It Work?

At its core, active metal brazing is a joining method that bonds ceramics to metals using a special filler alloy that contains “active” elements such as titanium, zirconium, or hafnium. These elements react chemically with the ceramic surface when heated, creating an ultra-strong bond.

The process usually happens inside a vacuum or inert atmosphere, at temperatures between 850°C and 1000°C. As the alloy melts, it wets the ceramic surface, and the active element forms reaction layers—like titanium oxide or titanium nitride—right at the interface. This reaction is what gives AMB its exceptional strength.

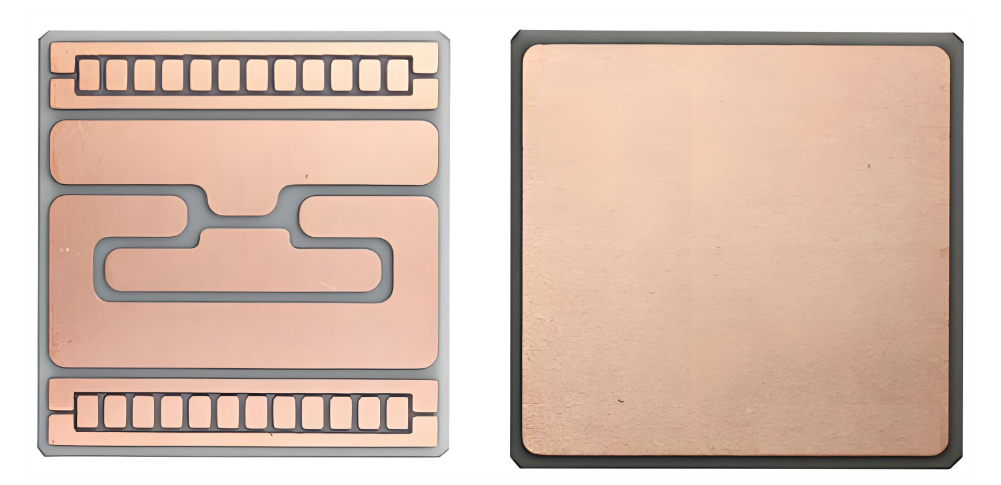

For example, a typical active metal brazing ceramic substrate might use aluminum nitride (AlN) or aluminum oxide (Al₂O₃) bonded with copper. This combination provides high thermal conductivity, electrical insulation, and strong adhesion—perfect for applications like power inverters and IGBT modules.

What Are the Main Materials Used in Active Metal Brazing Substrate?

The performance of active metal brazing amb depends heavily on material selection. Both the filler metal and the base materials (ceramic and metal) must be carefully chosen to ensure thermal expansion compatibility and chemical stability.

Common Ceramic Materials

- Aluminum Oxide (Al₂O₃):

Known for its mechanical strength and cost-effectiveness, Al₂O₃ is often paired with copper or molybdenum. It’s widely used in power devices and insulators.

- Aluminum Nitride (AlN):

Offers higher thermal conductivity than alumina and lower dielectric loss, ideal for high-power applications such as IGBT modules and power inverters.

- Silicon Nitride (Si₃N₄):

Exhibits excellent thermal shock resistance and mechanical strength, often used in automotive and aerospace applications.

Common Metal Materials

- Copper (Cu): Excellent thermal and electrical conductor, widely used for substrates.

- Molybdenum (Mo): Offers better thermal expansion match with ceramics.

- Tungsten (W): Used where high-temperature resistance is crucial.

Active Brazing Alloys (ABA)

Filler alloys used in AMB typically consist of silver (Ag), copper (Cu), or nickel (Ni) base combined with active elements. For example:

- Ag–Cu–Ti alloy is one of the most popular systems.

- Cu–Sn–Ti or Ni–Ti alloys are used for high-temperature applications.

Each alloy composition determines the wetting behavior and joint reliability. Choosing the right system depends on the ceramic’s chemistry and the operational environment.

Why Are Active Metal Brazing Ceramic Substrates So Popular?

If you look at how active metal brazing ceramic substrates perform compared to other joining methods, it’s easy to see why they’re so widely used.

1. Exceptional Bond Strength

The bond isn’t just surface-level—it’s chemical. This means the ceramic and metal essentially become one unit, able to handle mechanical and thermal stress for years without failure.

2. Great Heat Management

AMB substrates are made for high-power environments. They conduct heat quickly and efficiently, preventing hot spots that could damage components.

3. Natural Electrical Insulation

Ceramics act as built-in insulators, allowing for compact layouts without risking electrical short circuits.

4. Hermetic Sealing

Because AMB joints are dense and void-free, they perform well in vacuum or pressurized systems where leaks can’t be tolerated.

5. Custom Design Flexibility

AMB supports a wide range of materials and geometries, so engineers can design modules that perfectly fit their thermal and electrical needs.

Simply put, AMB substrates make devices stronger, cooler, and more dependable.

AMB Ceramic Substrate vs. DBC Ceramic Substrate

Both AMB and DBC ceramic PCBs combine excellent heat dissipation with strong electrical insulation, making them ideal for automotive, industrial, and power module applications. However, the difference lies in how the copper layer bonds to the ceramic substrate and how each method performs under thermal, mechanical, and environmental stress. Below is a detailed comparison that highlights how these two technologies stack up in performance, reliability, and cost.

| Parameter | AMB Ceramic PCB | DBC Ceramic PCB |

| Full Name | Active Metal Brazed Ceramic PCB | Direct Bonded Copper Ceramic PCB |

| Bonding Method | Copper is bonded to ceramic using active metal brazing (usually Ti or Zr-based alloys) | Copper is bonded directly to ceramic through an oxidation and diffusion process |

| Bonding Temperature | ~850–1000°C | ~1065°C |

| Bonding Strength | Very high (strong metallurgical bond due to active elements) | High, but slightly lower than AMB |

| Ceramic Material Options | AlN, Si₃N₄, Al₂O₃ | Al₂O₃, AlN |

| Thermal Conductivity | Excellent, especially with AlN or Si₃N₄ substrates | Good, depends on ceramic type (AlN > Al₂O₃) |

| Electrical Insulation | High | High |

| Thermal Expansion (CTE Match) | Better matched with power devices due to flexible alloy layer | Slightly less matched, may stress under thermal cycling |

| Copper Thickness Range | 0.2–1.0 mm | 0.3–0.8 mm |

| Surface Flatness | Very smooth, suitable for high-precision mounting | Smooth, but not as ideal for thin layers |

| Typical Applications | High-power automotive, EV inverters, power modules, IGBT substrates | Power modules, LEDs, RF devices, industrial control |

| Reliability Under Thermal Cycling | Excellent (superior resistance to cracking) | Good, but can degrade under repeated cycling |

| Manufacturing Cost | Higher due to complex brazing process | Lower, mature and cost-effective |

| Main Advantage | Exceptional reliability and thermal performance for demanding environments | Cost-effective and widely available |

| Main Limitation | Higher cost and more complex fabrication | Limited in high-stress or high-current conditions |

AMB Substrate Applications

- Power Modules: Used in EVs, renewable energy, and industrial drives. They keep heat under control and extend lifespan.

- LED Lighting: High-power LEDs need strong heat dissipation, and AMB substrates handle that with ease.

- Automotive Inverters: As electric vehicles evolve, AMB provides thermal stability and vibration resistance.

- Aerospace Components: Critical systems require joints that won’t fail under pressure or temperature extremes.

- Medical Devices and RF Equipment: Their hermetic sealing and precision bonding support sensitive, high-frequency electronics.

What Are the Challenges in Active Metal Brazing?

Even with its many benefits, active metal brazing does come with challenges. The biggest one is managing the thermal expansion difference between metal and ceramic. If not balanced properly, it can create internal stress that leads to cracking.

The process also demands an extremely clean and controlled environment. Even a small trace of oxygen or moisture can interfere with the reaction between the active metal and ceramic surface.

Another consideration is the thickness of the interfacial reaction layer. If it becomes too thick, it may reduce ductility and make the joint brittle. That’s why tight temperature control and precise timing are so important.

Still, with the right design and quality control, these issues can be easily managed.

Recent Advances in Active Metal Brazing of Ceramics and Process

The field of active metal brazing has seen big improvements in recent years. Researchers and manufacturers are constantly exploring ways to make joints even stronger, cleaner, and more consistent. Some of the latest developments include:

1. Nano-Enhanced Alloys

Adding nanoparticles like TiC or TiB₂ to the brazing filler improves how the molten alloy wets the ceramic. It also reduces voids and creates smoother interfaces, boosting long-term reliability.

2. Improved Surface Treatments

Using plasma or ion cleaning before brazing makes the ceramic surface more reactive. This promotes better wetting and stronger chemical bonding without damaging the base material.

3. Low-Temperature Brazing Alloys

New filler compositions allow brazing at lower temperatures, which minimizes residual stress from thermal expansion differences. This is a huge advantage for thinner or more fragile components.

4. Process Simulation Tools

Finite element analysis (FEA) now helps predict how the interface will behave under stress and temperature changes, reducing the need for trial runs.

5. Greener Manufacturing

Modern AMB techniques favor lead-free, flux-free systems that are safer for the environment and easier to manage in clean production lines.

Together, these recent advances in active metal brazing of ceramics and process design have helped manufacturers produce cleaner, stronger, and more stable joints—supporting the next generation of high-performance electronics.

Why Partner with EBest Circuit (Best Technology) for Active Metal Brazing Substrates?

At EBest Circuit (Best Technology), we take pride in producing reliable active metal brazing ceramic substrates tailored for the most demanding applications. Our AMB products are used in automotive power modules, aerospace equipment, medical systems, and industrial electronics worldwide.

From selecting the right ceramic-to-metal pair to optimizing brazing parameters, we help clients achieve designs that balance performance, reliability, and cost. Whether it’s aluminum oxide or aluminum nitride with copper, molybdenum, or tungsten, our active metal brazing amb technology delivers long-term stability and consistent quality.

We’re certified under ISO9001, ISO13485, IATF16949, and AS9100D, ensuring every process meets strict global standards. Our vacuum brazing systems and MES-controlled production lines guarantee full traceability from raw material to finished substrate. If you’re seeking dependable substrates for your high-power projects, EBest Circuit (Best Technology) can be your trusted partner.

FAQs

1. What temperature does active metal brazing use?

Typically between 850°C and 1000°C, depending on the alloy and materials used.

2. Why is titanium important in AMB?

Titanium is the “active” element that reacts with ceramics, creating a strong chemical bond.

3. Can AMB join both aluminum oxide and aluminum nitride?

Yes, both are popular choices for AMB substrates due to their strength and insulation.

4. How is AMB different from DBC substrates?

DBC (Direct Bonded Copper) relies on oxidation bonding, while AMB uses a reactive alloy for a stronger chemical interface.

5. How does EBest Circuit (Best Technology) ensure AMB quality?

Through vacuum brazing, 100% inspection, full MES traceability, and globally recognized quality certifications.

Tags: active metal brazing ceramic pcb, active metal brazing substrate, active metal brazing, amb active metal brazing, recent advances in active metal brazing of ceramics and process