PTFE copper clad laminate is one of the most important base materials in high-frequency printed circuit boards. It is made by bonding copper foil with PTFE, also known as polytetrafluoroethylene. This material is widely used in microwave, RF, and high-speed digital circuits where low signal loss and stable performance are critical.

While FR-4 laminates serve well in general electronic devices, PTFE laminates take performance to another level. Their unique dielectric properties and stability in harsh conditions have made them the preferred choice in aerospace, defense, 5G communication, radar, and advanced automotive systems.

In this blog, we will explore what PTFE copper clad laminate is, its electrical characteristics, why industries rely on it, and how EBest Circuit (Best Technology) can support you with reliable supply and engineering expertise.

What is PTFE Copper Clad Laminate in PCB Manufacturing?

PTFE copper clad laminate is a composite base material created by pressing a thin copper sheet onto a PTFE substrate. PTFE is well known for its chemical resistance and low dielectric constant. When combined with copper, it forms a highly stable laminate for circuit fabrication.

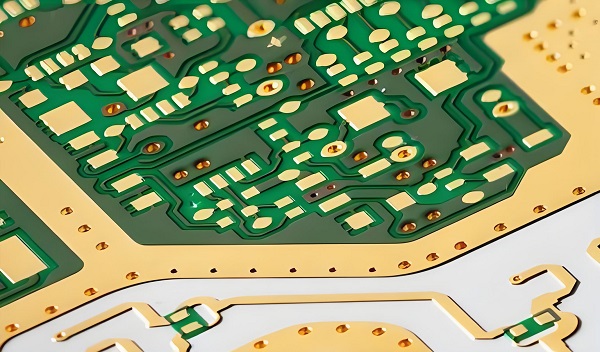

This material serves as the foundation for etching circuit patterns and creating transmission lines in PCBs. Because PTFE exhibits excellent electrical insulation and thermal stability, it is the go-to choice for applications requiring precision in high-frequency ranges.

Unlike traditional laminates, PTFE-based materials are engineered specifically to handle sensitive signals. They support microstrip lines, stripline designs, and other controlled impedance circuits that are essential for RF engineering.

How Does PTFE Differ from FR4 in PCB Laminates?

The biggest difference between PTFE and FR4 laminates lies in their dielectric and thermal performance. FR4, made of woven fiberglass and epoxy resin, offers sufficient electrical insulation for consumer electronics, but it falls short when frequencies increase.

FR4 typically has a dielectric constant (Dk) around 4.2â4.5, while PTFE laminates maintain values as low as 2.0â2.2. This lower Dk allows signals to travel faster with reduced delay.

Another key point is loss tangent, or dissipation factor (Df). FR4 materials may reach 0.02 or higher, whereas PTFE stays around 0.0009â0.002, which is far more efficient for high-frequency circuits.

Thermal stability is also superior. FR4 begins to degrade around 130â150°C, while PTFE-based laminates can withstand much higher ranges without major performance shifts. This is vital for aerospace and military systems exposed to extreme conditions.

Simply put, when precision, speed, and minimal loss matter, PTFE laminates outperform FR4 by a wide margin.

What Are the Electrical Properties of PTFE Copper Clad Laminate?

The electrical properties of PTFE laminates are the reason they are so valuable. Some key characteristics include:

| Property | Typical Value | Significance in PCB Design |

| Dielectric Constant (Dk) | 2.0 â 2.2 (stable across frequency) | Lower Dk allows faster signal propagation with reduced delay. |

| Dissipation Factor (Df) | 0.0009 â 0.002 | Extremely low loss, minimizing signal attenuation in high-frequency circuits. |

| Dielectric Strength | > 500 V/mil | Provides strong insulation, preventing electrical breakdown under stress. |

| Moisture Absorption | < 0.01% | Almost zero water uptake, ensuring stable performance in humid environments. |

| Volume Resistivity | > 10¹ⵠΩ·cm | Maintains excellent insulation resistance even under thermal or electrical stress. |

| Thermal Stability | High (usable above 200°C) | Supports reliable operation in aerospace, automotive, and defense electronics. |

Why is PTFE Copper Clad Laminate Important for High-Frequency PCBs?

At high frequencies, even small material imperfections can distort signals. PTFE laminates minimize these risks with their stable dielectric constant and low loss tangent. This results in clear signal transmission, which is crucial for RF and microwave devices.

In applications such as radar, phased-array antennas, and satellite communication, accuracy cannot be compromised. PTFE laminates deliver repeatable performance even when exposed to temperature shifts, high power levels, or mechanical stress.

Another reason for their importance is impedance control. Designing circuits at GHz frequencies requires precise line widths and predictable laminate behavior. PTFE offers that predictability, which helps engineers design with confidence.

Without PTFE laminates, many of todayâs wireless and defense technologies would not function with the required accuracy and reliability.

What Are the Common Applications of PTFE Copper Clad Laminates?

PTFE copper clad laminates are widely used in industries where high-frequency performance is a must. Some typical applications include:

- 5G Communication Systems: For antennas, base stations, and signal routers.

- Aerospace and Defense: In radar modules, missile guidance systems, and avionics.

- Automotive Electronics: Used in advanced driver-assistance systems (ADAS) and vehicle radar.

- Medical Equipment: Applied in MRI systems and diagnostic imaging requiring clear signals.

- Satellite and Space Communication: Critical for stable transmission in extreme environments.

- High-Speed Digital Devices: Essential for data centers and supercomputers handling large bandwidths.

These industries cannot afford distortion, delay, or instability. PTFE laminates provide the reliability needed for next-generation technologies.

What Are the Processing Challenges of PTFE Laminates in PCB Fabrication?

While PTFE laminates deliver outstanding electrical performance, they are not the easiest to process. Manufacturers face several challenges, such as:

- Softness of PTFE: The material is softer than FR4, making drilling and machining more complex. Specialized bits are often required.

- High Thermal Expansion: PTFE expands more under heat, which demands careful process control during lamination.

- Bonding Issues: PTFEâs chemical resistance makes it harder for copper to adhere without special treatments or bonding films.

- Dimensional Stability: Without proper handling, warping may occur.

These challenges increase fabrication costs compared to standard FR4 boards. However, experienced PCB manufacturers, like EBest Circuit (Best Technology), have developed methods to manage these issues efficiently. The result is reliable, high-performance boards without compromising quality.

How Does PTFE Copper Clad Laminate Improve Signal Performance?

Signal performance is the main advantage of PTFE laminates. With their low Dk and Df, signals pass through the board with less distortion and attenuation. This is especially critical in RF designs where even small losses translate into reduced range or efficiency.

The reduced dielectric loss improves power handling as well. Devices such as power amplifiers benefit from higher efficiency, which lowers energy waste and heat generation.

Additionally, PTFE laminates reduce cross-talk between adjacent lines. This improves signal isolation and helps maintain cleaner communication channels, a necessity in high-density RF layouts.

Overall, PTFE laminates provide the foundation for achieving superior signal clarity, speed, and reliability in demanding applications.

Where Can You Buy Reliable PTFE Copper Clad Laminate PCBs?

Not every PCB supplier is equipped to process PTFE laminates. The material requires specialized equipment, expertise, and strict quality control. When choosing a supplier, factors like certifications, engineering support, and track record in high-frequency boards are important.

EBest Circuit (Best Technology) is a trusted manufacturer of advanced PCBs, including PTFE-based designs. With certifications such as ISO9001, ISO13485, IATF16949, and AS9100D, the company meets stringent standards for industries ranging from medical to aerospace.

Using an MES system, EBest Circuit (Best Technology) guarantees traceability of every component and process step. Combined with competitive pricing and a highly skilled engineering team, the company provides dependable solutions for complex PCB needs.

Whether you require prototypes or volume production, EBest Circuit (Best Technology) offers PTFE copper clad laminate PCBs tailored to your application.

Conclusion

PTFE copper clad laminates are at the core of modern high-frequency electronics. Their unique electrical characteristicsâlow dielectric constant, minimal loss, and excellent stabilityâmake them essential for applications in 5G, radar, aerospace, and beyond.

While they are more challenging to process than FR4, the advantages in performance far outweigh the difficulties. Partnering with an experienced manufacturer ensures you get the benefits without the risks.

At EBest Circuit (Best Technology), we combine strict quality systems, professional engineering support, and advanced manufacturing capabilities to deliver reliable PTFE-based PCBs. Our certifications across medical, automotive, and aerospace industries reflect our commitment to excellence. If you are looking for a partner to support your high-frequency designs, EBest Circuit (Best Technology) is ready to help.

FAQs

1. What is the dielectric constant of PTFE copper clad laminate?

The dielectric constant is typically 2.0â2.2, stable across different frequencies and temperatures.

2. Is PTFE copper clad laminate suitable for 5G PCBs?

Yes, it is widely used in 5G base stations, antennas, and routers due to its low signal loss.

3. What is the cost difference between PTFE laminate and FR4?

PTFE laminates are more expensive because of material cost and processing complexity, but their performance justifies the price in high-frequency applications.

4. Can PTFE copper clad laminate handle high temperatures?

Yes, PTFE laminates perform reliably under high thermal conditions, making them suitable for aerospace and automotive environments.

5. How do you choose the right PTFE laminate supplier?

Look for certifications, proven experience in high-frequency PCBs, and advanced quality systems like MES for process traceability.