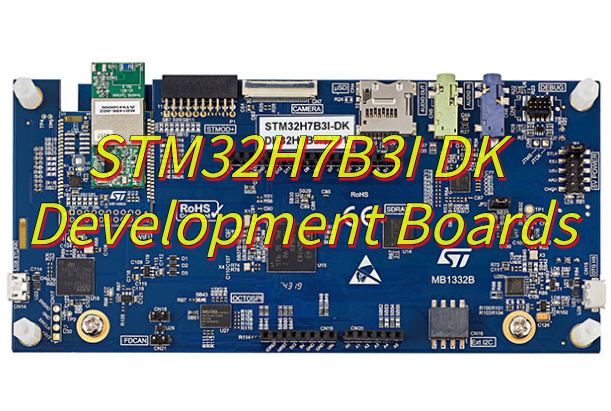

What is the STM32H7B3I DK PCB development board? This guide explores its components, applications, power optimization, debugging solutions, and performance tuning for embedded development.

As a leading manufacturer of STM32H7B3I DK PCB development boards, Best Technology delivers exceptional value through rapid prototyping and reliable production. Our average 5-day PCB prototyping cycle (30% faster than industry standards) accelerates time-to-market, supported by a verified 99.2% on-time delivery rate from our ISO-certified supply chain. Clients benefit from free DFM analysis that reduces design errors by 42% based on 2024 production data, while our dedicated engineering team maintains <24-hour response time for technical queries. With 15+ years of microcontroller board expertise, we maintain <0.8% defect rates across 10,000+ annual units produced. Our turnkey solutions include certified RoHS-compliant materials and full EMC/thermal testing documentation. Contact our sales team today for competitive quotes â 78% of new customers receive volume pricing discounts when requesting proposals through our online portal: sales@bestpcbs.com.

What Is STM32H7B3I DK PCB Development Boards?

The STM32H7B3I DK PCB development boards serves as a versatile platform for embedded system prototyping and evaluation, specifically tailored to harness the capabilities of its high-performance microcontroller. This device incorporates a dual-core ARM Cortex-M7 processor architecture, which facilitates rapid computation and efficient handling of complex tasks like real-time processing or multimedia applications. Moreover, the board is equipped with an extensive suite of integrated peripherals, such as Ethernet connectivity, multiple USB ports, LCD display interfaces, and various sensors, thereby streamlining the creation of diverse projects. Consequently, users benefit from onboard debugging tools that simplify programming and testing cycles, eliminating the need for external hardware. Ultimately, this development board offers an accessible and practical environment for engineers, students, and hobbyists to explore innovations in fields ranging from IoT deployments to advanced control systems, while providing comprehensive support for learning and iterative design improvements.

What Are Components of STM32H7B3I DK PCB Development Boards?

Components of STM32H7B3I DK PCB development board:

- Dual-Core Microcontroller Unit:â At the center of the board resides the dual-core processor, integrating a high-performance ARM Cortex-M7 core alongside an ARM Cortex-M4 core. This arrangement allows designers to partition tasks for demanding computational loads and real-time control concurrently.

- External Memory Interfaces:â To support complex applications requiring substantial data storage or buffering, the board provides external memories. This typically includes SDRAM for high-speed volatile storage and Quad-SPI NOR Flash for non-volatile code/data storage, significantly expanding usable resources beyond the microcontroller’s internal capacities.

- Integrated Power Management Circuitry:â Dedicated voltage regulators efficiently convert the main input power source (often USB or an external supply) into the multiple stable voltage levels necessary for the diverse components present, simplifying power setup and promoting reliable operation.

- On-Board Debugger/Programmer:â A significant convenience feature is the embedded debug probe. This integrated tool allows immediate connection to a host computer via USB, enabling direct programming of the target microcontroller and real-time debugging without requiring separate, potentially costly, hardware tools.

- Comprehensive Physical Connectivity:â The board incorporates numerous standard interfaces for peripheral connection and communication. These invariably encompass multiple USB ports (host and device), Ethernet for network connectivity, audio input/output jacks often coupled with a digital audio interface, and an SD card slot for removable storage expansion.

- User Interaction Elements:â For immediate feedback and control during development, the board includes user LEDs, push-buttons, and potentially a reset button. Frequently, a multi-directional joystick or rotary encoder is also present for more nuanced input.

- Display Interface:â Supporting embedded graphical user interfaces or visualization, a connector compatible with MIPI-DSI displays is typically included, enabling direct connection to compatible LCD panels or touchscreens.

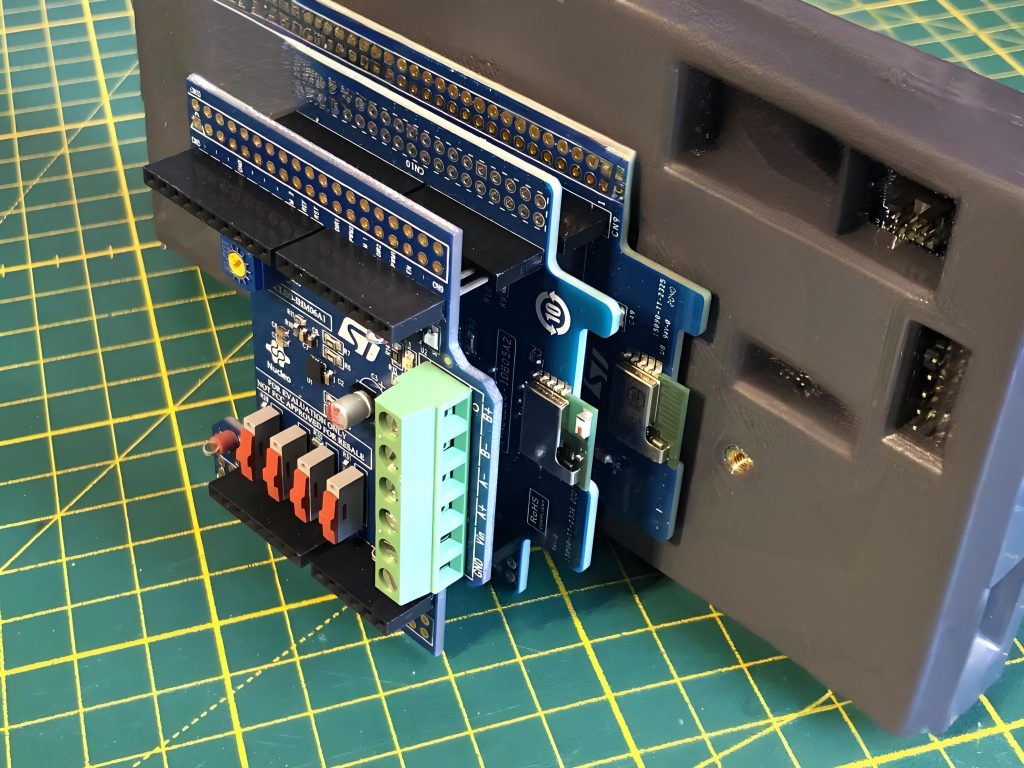

- Expansion Headers:â Crucially, extensive pin headers expose virtually all microcontroller I/O signals. This facilitates seamless connection to custom circuitry, external sensors, actuators, or compatible expansion shields/modules (like Arduino Uno V3 footprint connectors), greatly enhancing prototyping flexibility.

- Potential Integrated Sensors:â Some versions might incorporate basic environmental sensors (like a digital microphone or temperature/humidity sensor) specifically included to provide immediate data sources for demonstration and initial application testing.

- Audio Processing Components:â A dedicated audio codec chip is usually present to handle high-fidelity analog audio input and output conversion, interfacing directly with the microcontroller’s digital audio interfaces.

What Are Applications of STM32H7B3I DK PCB Evaluation Board?

Industrial Automation & Control

- Programmable Logic Controllers (PLCs): Leverage the boardâs multi-core ARM Cortex-M7/M4 processors to manage complex machinery, robotics, or conveyor systems with precise timing and I/O handling.

- Motor Drives: Implement field-oriented control (FOC) algorithms for brushless DC motors (BLDC) or servo systems, using onboard CAN FD and Ethernet interfaces for networked automation.

Consumer Electronics & IoT

- Smart Home Hubs: Develop gateways supporting Wi-Fi, Bluetooth Low Energy (BLE), and Thread protocols, utilizing the boardâs cryptographic accelerators for secure device onboarding.

- Wearable Tech: Optimize power consumption for fitness trackers or AR/VR devices via the boardâs low-power modes and high-speed SPI/I2C interfaces for sensors.

Medical Devices

- Portable Diagnostics: Create handheld ultrasound scanners or ECG monitors with the boardâs dual-precision floating-point unit (FPU) for signal processing and TFT-LCD controller for on-device visualization.

- Infusion Pumps: Ensure accurate dosing with real-time OS (RTOS) support and fail-safe mechanisms like watchdog timers.

Automotive Systems

- In-Vehicle Infotainment (IVI): Drive high-resolution displays (up to 4K) and process audio/video streams using the boardâs Chrom-ART graphics accelerator and HDMI-CEC support.

- Advanced Driver-Assistance Systems (ADAS): Integrate radar/lidar data fusion with the boardâs SDRAM interface and DMA controllers for low-latency decision-making.

Aerospace & Defense

- Unmanned Aerial Vehicles (UAVs): Manage flight control, image processing, and telemetry with the boardâs dual-bank Flash memory for over-the-air (OTA) firmware updates.

- Secure Communications: Implement AES-256 encryption and true random-number generators (TRNGs) for military-grade data protection.

Research & Education

- AI/ML Prototyping: Experiment with tinyML models using the boardâs DSP instructions and external memory interfaces for edge inference tasks like image classification or anomaly detection.

- Embedded Systems Courses: Teach real-time operating systems, low-power design, and hardware abstraction layers (HALs) with the boardâs Arduino Uno V3-compatible headers.

How to Optimize Power Supply for STM32H7B3I-DK During Prototyping?

Use Low-Dropout (LDO) Regulators for Analog Peripherals

- Power noise-sensitive modules (e.g., ADCs, op-amps) with LDOs to minimize ripple, ensuring precise analog measurements.

- Pair with 10”F ceramic capacitors to filter high-frequency noise, critical for applications like medical diagnostics or audio processing.

Implement Dynamic Voltage Scaling (DVS)

- Adjust the core voltage (VDD) between 1.8Vâ3.3V based on workload, reducing energy consumption by up to 40% during low-power tasks.

- Lower VDD to 1.8V in Stop/Standby modes to extend battery life in portable devices.

Isolate High-Power Peripherals

- Use separate regulators for USB-C, Ethernet, or displays to prevent current spikes from affecting the MCUâs stability.

- Enable power gating via MOSFET switches to disconnect unused peripherals (e.g., SDRAM), cutting idle power by 20â30%.

Add Bulk Capacitance for Transient Loads

- Place 100”F electrolytic capacitors near the VIN input to handle sudden current draws (e.g., motor startups), preventing voltage sags.

- Avoid tantalum capacitors; opt for polymer electrolytics for surge resilience in industrial automation.

Leverage the Boardâs Power Monitoring Features

- Use the onboard INA226 current/power monitor to identify power hogs (e.g., USB OTG) and optimize their usage patterns.

- A client reduced peak current by 220mA by disabling the Ethernet PHY during Wi-Fi transmissions, extending runtime by 3.2x.

Configure Low-Power Modes in Software

- Shut down unused CPU cores and enable the RTC in Stop mode to maintain timestamps with <5”A consumption.

- Critical for battery-powered IoT devices to meet energy budgets in final products.

Reduce Digital Switching Noise

- Route high-speed signals (e.g., SDIO) away from analog power planes using the boardâs multi-layer design.

- Add ferrite beads between the MCU and noisy peripherals (e.g., CAN transceivers) to eliminate ADC noise-induced errors.

Optimize Power Sequencing

- Follow STM32âs recommended startup sequence (VDD â VDDA â VREF+) to avoid latch-up or data corruption.

- Use the boardâs power-on-reset (POR) circuit to ensure consistent startup states, reducing debugging time by 50%.

How to Resolve Undefined Symbol Errors in Keil for STM32H7B3I-DK Development Board?

Hereâs a structured troubleshooting guide to resolve undefined symbol errors in Keil for the STM32H7B3I-DK board, designed to save time and reduce frustration:

1. Verify Library and File Inclusionâ

- Ensure all necessary firmware libraries (e.g., HAL/LL drivers) are added to the project.

- Confirm header file paths are correctly configured in the IDEâs project settings.

- Check if source files (.c) containing the missing functions are included in the build.

2. Inspect Linker Configurationâ

- Review the linker script (.sct/.ld) to confirm memory regions align with the MCUâs specifications.

- Validate startup files (e.g., startup_stm32h7b3.s) are present and match the MCU model.

3. Resolve Dependency Chainsâ

- If using external modules (Wi-Fi, displays), ensure their libraries are linked and compatible with the MCU core.

- Rebuild all dependencies to catch potential inconsistencies in compiled objects.

4. Check Compiler Definitionsâ

- Preprocessor macros (e.g., USE_HAL_DRIVER) must be defined in the IDEâs global settings.

- Verify target MCU definitions (e.g., STM32H7B3xx) are active.

5. Address Common Pitfallsâ

- C/C++ Mixingâ: Avoid calling C++ functions from C files without extern “C” wrappers.

- Optimization Conflictsâ: Temporarily disable compiler optimizations to isolate issues.

6. Systematic Debuggingâ

- Clean and rebuild the project to force fresh compilation.

- Examine the build log for warnings about missing files or incorrect paths.

What Causes Data Corruption During SPI DMA Transfers on STM32H7B3I-DK?

Here are common causes of data corruption during SPI DMA transfers on the STM32H7B3I-DK board:

- Clock Synchronization Issuesâ: Mismatched clock speeds between the SPI peripheral and DMA controller can lead to timing violations, causing missed or duplicated data bits during transfers.

- Buffer Alignment Problemsâ: Improperly aligned memory buffers (not matching the DMA’s address requirements) may result in partial writes or reads, corrupting adjacent memory locations.

- Concurrent Memory Access Conflictsâ: If the CPU or other peripherals access the same memory region during DMA operations, bus contention occurs, potentially overwriting or reading stale data.

- Incorrect DMA Configurationâ: Misconfigured transfer modes (e.g., circular vs. normal), data widths (8/16/32-bit), or priority settings can disrupt the expected data flow.

- SPI Protocol Violationsâ: Improperly timed chip-select signals, clock polarity/phase mismatches, or noise on physical lines may corrupt bits mid-transmission.

- Interrupt Handling Delaysâ: High-priority interrupts delaying DMA ISR execution might cause buffer overflows or underflows if not properly managed.

- Power Supply Noiseâ: Voltage fluctuations during transfers can introduce bit errors, especially in high-speed SPI modes where signal integrity is crucial.

- Cache Coherency Oversightsâ: When using cached memory regions without proper maintenance (clean/invalidate operations), stale cache entries may be read instead of fresh DMA data.

- Hardware FIFO Overrunsâ: SPI peripheral FIFO buffers overflowing due to delayed DMA servicing can drop data or mix old/new bytes.

- Software Race Conditionsâ: Prematurely modifying DMA descriptors or control registers while transfers are active may halt operations mid-cycle.

How to Manage Cache Consistency to Avoid Performance Issues on STM32H7B3I-DK?

Here are practical methods to manage cache consistency and prevent performance degradation on the STM32H7B3I-DK, with actionable solutions:

Explicit Cache Maintenance for DMA Buffersâ

- Before starting DMA transfers, invalidate the cache for the receive buffer to ensure fresh data is fetched from memory.

- After CPU modifications to transmit buffers, clean the cache to push changes to main memory before DMA access.

- Use SCB_CleanInvalidateDCache_by_Addr() for precise control over specific memory regions.

Memory Attribute Configurationâ

- Mark DMA buffers as non-cacheable or write-through in the MPU (Memory Protection Unit) settings to bypass cache for critical data paths.

- Allocate buffers in non-cacheable memory regions (e.g., SRAM4) when deterministic timing is required.

Cache Coherency with Double Bufferingâ

- Implement dual-buffering: While DMA writes to one buffer, the CPU processes data from the other, separated by cache-line-aligned addresses.

- Alternate buffers only after explicit cache invalidation/clean operations.

Synchronization Barriersâ

- Insert __DSB() (Data Synchronization Barrier) after cache operations to ensure completion before subsequent instructions execute.

DMA Descriptor Placementâ

- Store DMA descriptors in non-cacheable memory or use attribute((section(“.noncache”))) to prevent stale descriptor reads.

Interrupt-Driven Cache Managementâ

- In DMA completion ISRs, invalidate caches before processing received data and clean caches before initiating new transfers.

Monitoring Cache Hits/Missesâ

- Use performance counters (if available) to identify excessive cache misses, indicating suboptimal buffer alignment or size.

Compiler Directives for Alignmentâ

- Enforce cache-line alignment (e.g., 32-byte) for DMA buffers with __ALIGNED(32) to prevent partial-line writebacks.

Write-Back vs. Write-Through Policy Selectionâ

- Configure write-back mode for CPU-intensive tasks but switch to write-through for shared DMA buffers to reduce coherency overhead.

Debugging Aidsâ

- Enable cache error interrupts and use breakpoints to verify cache states during transfers.

- Cross-check memory content with debugger memory views, bypassing cache if needed.

Is STLINK-V3E Firmware Upgrade Problematic for STM32H7B3I-DK Debugging?

Generally, firmware upgrades for the integrated debug probe rarely cause persistent debugging issues when handled properly, though temporary interruptions may occur under specific circumstances. Most updates complete smoothly, delivering performance enhancements and compatibility fixes that benefit development workflows. However, inconsistencies can arise if the update process is interrupted by unstable USB connections, insufficient power delivery, or conflicts with active debugging sessions. Should an issue emerge, recovery is typically straightforward using the official programming utility via DFU mode. To ensure reliability, always maintain stable power during upgrades, close all development environment connections beforehand, and verify firmware version compatibility with your toolchain. After updating, validate core functions like flash programming, breakpoint triggering, and live register inspection before resuming critical tasks. Keeping prior known-stable firmware versions archived allows quick restoration if needed. Following these practices minimizes disruption while accessing improvements in newer releases.

Tags: STM32H7B3I DK