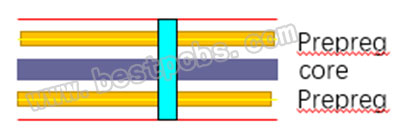

Before leaving PCB manufacturing line, bare PCBs (Printed Circuit Boards) have to pass electrical tests so that it guarantee that boards go for high performance and high reliability after finish the SMT(Surface Mount Technology). Electrical tests are implemented to find out electrical and circuitry issues such as shorts, opens, resistance, capacitance etc. all of which indicate whether bare boards or assembled board are correctly fabricated.

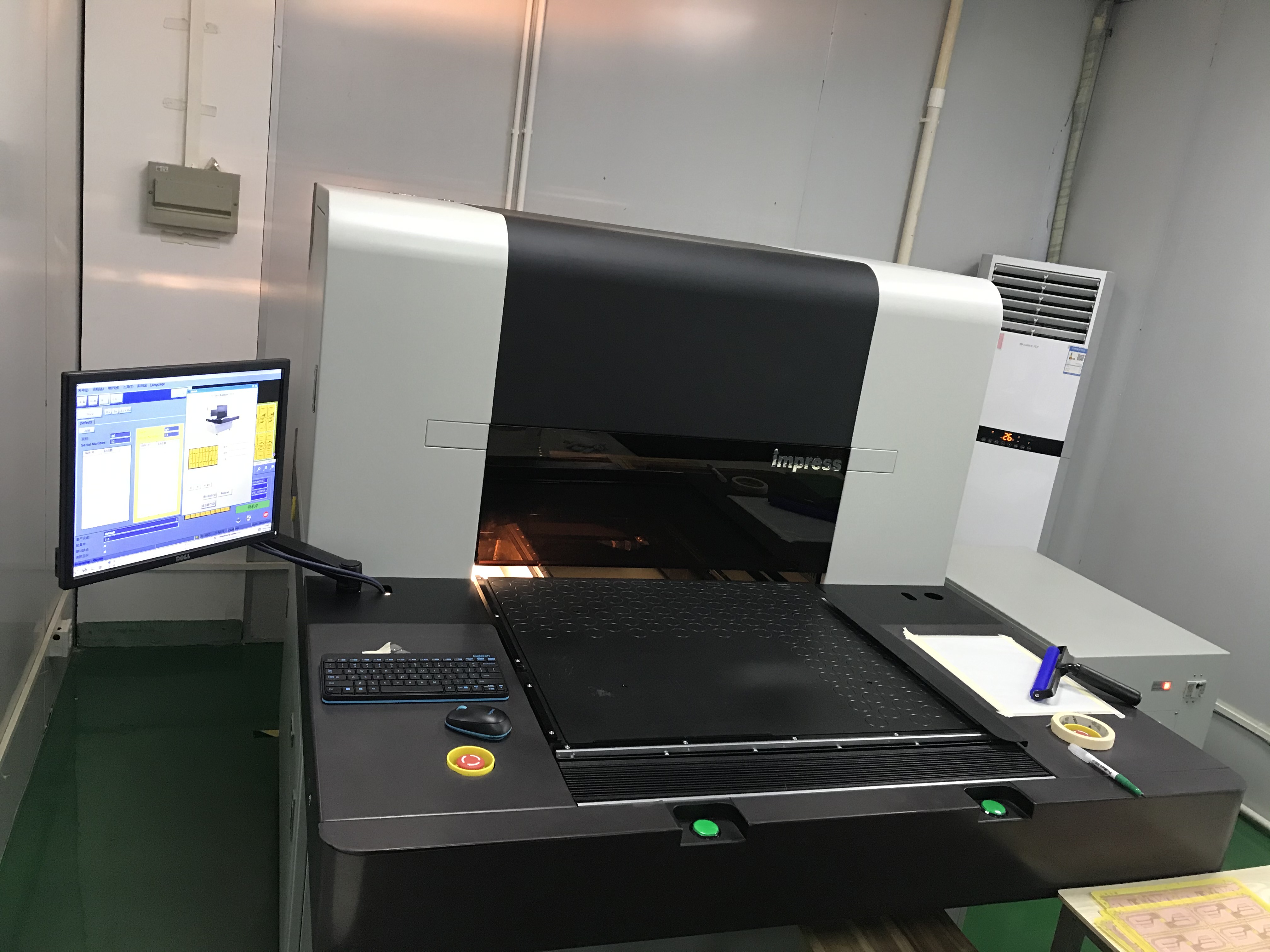

When test probes work, it moves quickly from test points to other test points as per instructions instructed by the computer set up program. Â

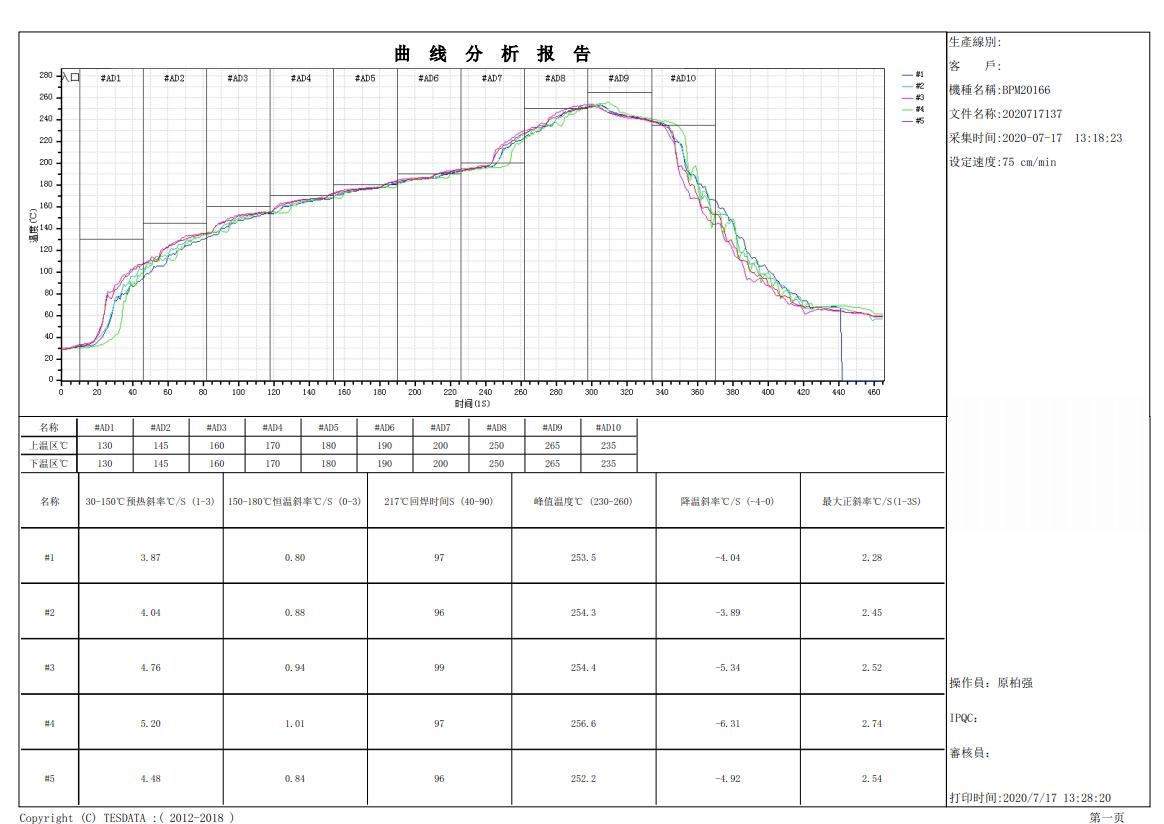

Probe test is no need fixture, so it is very popular in the printed circuit boards manufacturing. The most significant reason is their cost. it is highly cost-effective for prototypes and low to mid-volume production. And the most important factor, the test reports can be provided for each board after finish tested and it is very easy to export from the computer, you can send to your customer very quickly for the test results of PCB.

Advantages of Flying Probe Test:

Low test cost (Eliminates fixturing costs and time)

Short test development time

Fast computer program development, easy integration of design changes

Rapid feedback provided to PCB design engineers at prototyping period

Process flexibility

Circuit access, even in the absence of test points

Controlled probe contact, programmable for any type of board

Different test solutions and approaches integrated in a single test system

Intrinsic positioning and measurement precision

Disadvantages of Flying Probe Test

Everything has two sides. Apart from obvious advantages, flying probe test have some disadvantages.

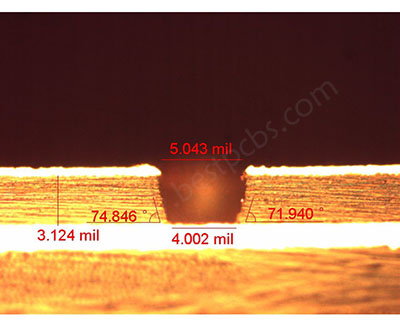

Since flying probes have direct physical contact with vias and test pads and small pits are easily caused on board surface, when flying probe tester is working on components without test pad, it’s possible that probes have contact with component leads so that loose leads or leads with badly-performed soldering may be missed.

In spite of the disadvantages mentioned, flying probe test is still regarded as a significant test method for PCB fabrication. Flying Probes have enhanced the competitive variable as lost time due to retooling has been removed. Prototype and Quick Turn product is the perfect match for Flying Probes as they carry out in low quantity orders and are quick to change jobs, unlike the long setup times with fixture testers.

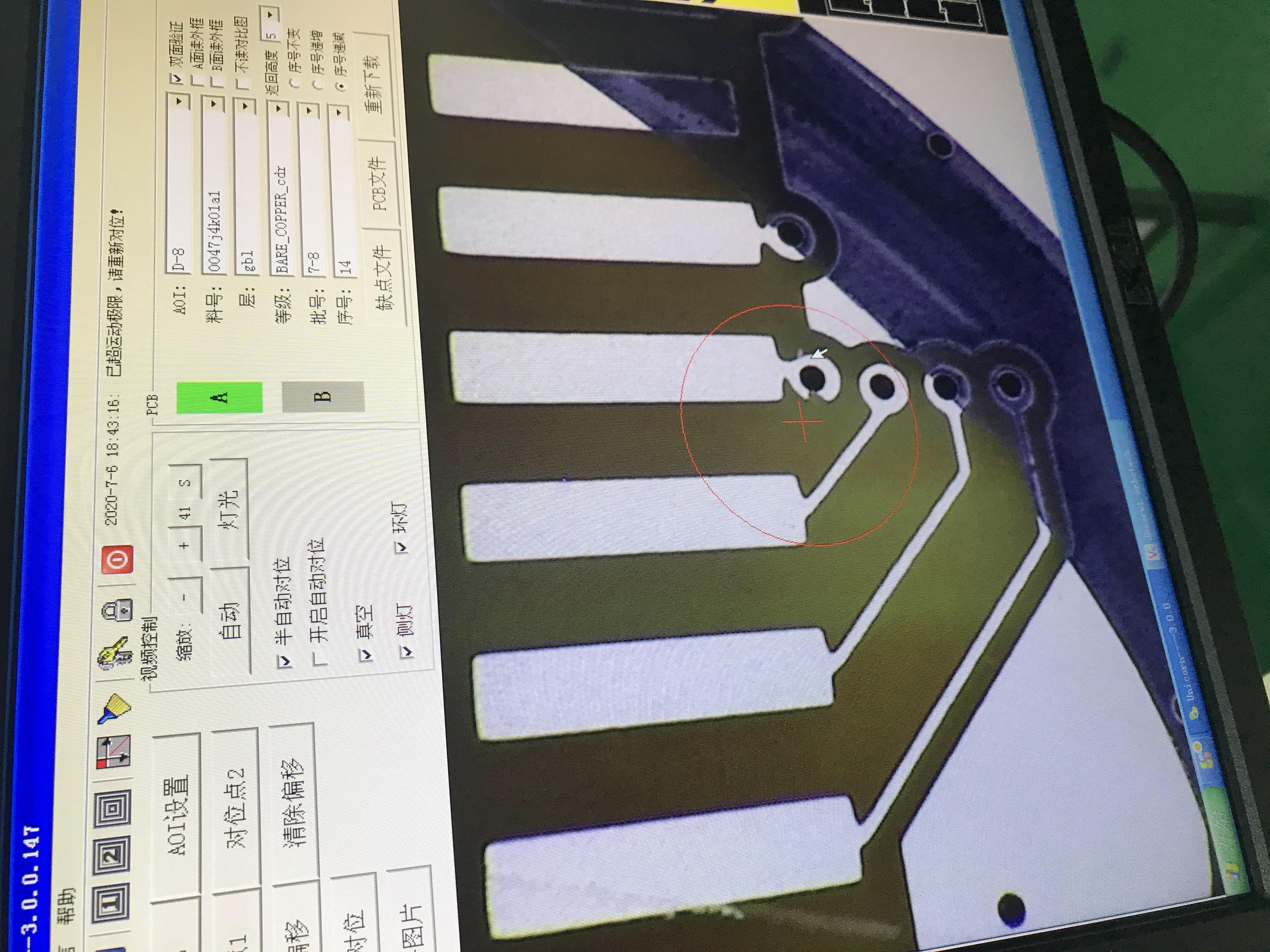

By the way, to test circuit shorts, opens, Best Technology also do AOI checking to make sure there is no issue for PCB manufacturing.

Contact Best Technology right now, to discuss more for printed circuit boards.