Have you ever encountered these problems: your LED beads overheat, lose brightness, and shorten their lifespan? Have you ever thought of using a better PCB material to solve these problems?

If you are considering this question and your answer is yes, then you must learn about thermal-electric separation copper PCB, the king of Metal Core PCB (MCPCB), which can make your LED lamps achieve unprecedented effects.

What is Metal Core PCB?

It is a type of printed circuit board that uses metal material as the heat dissipation layer, commonly used in LED and other high-power electronic products. There are many types of metal core PCB, among which the most common one is aluminum PCB, which has a thermal conductivity of about 1W, suitable for low-power LED lamps.

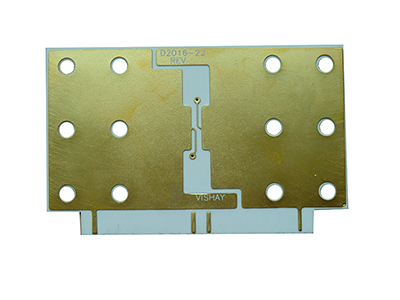

However, with the development of high-power electronic products and high-frequency PCBs, aluminum PCBs can no longer meet the requirements of heat dissipation and volume. Therefore, more and more products choose copper PCB, which has a thermal conductivity of up to 400W, 400 times that of aluminum PCB. But ordinary copper PCB also has a drawback, that is, its circuit layer and heat layer are on the same layer, which requires connecting the beads and the heat layer through an insulating thermal conductive material, which will reduce the thermal efficiency. To solve this problem, a more advanced copper PCB structure has emerged, called thermal-electric separation copper PCB or SinkPad PCB.

Introduction to Thermal-electric Separation Copper PCB

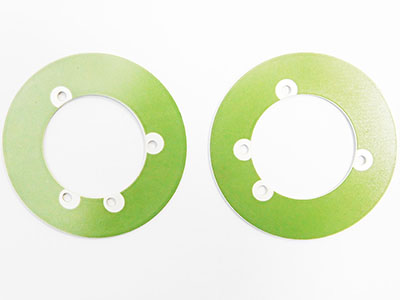

The feature of thermal-electric separation copper PCB is that its circuit layer and heat layer are on different layers so that the beads can directly contact the heat layer, achieving zero thermal resistance heat dissipation. This structure can greatly improve the luminous efficiency and lifespan of the beads, and reduce light decay and heating. Thermal-electric separation copper PCB is very suitable for single high-power beads, especially the COB package, which can make the lamp achieve better effects. In addition, thermal-electric separation copper PCB can also be made into different shapes and structures according to different design needs, such as copper protrusions, copper recesses, parallel heat dissipation, etc.

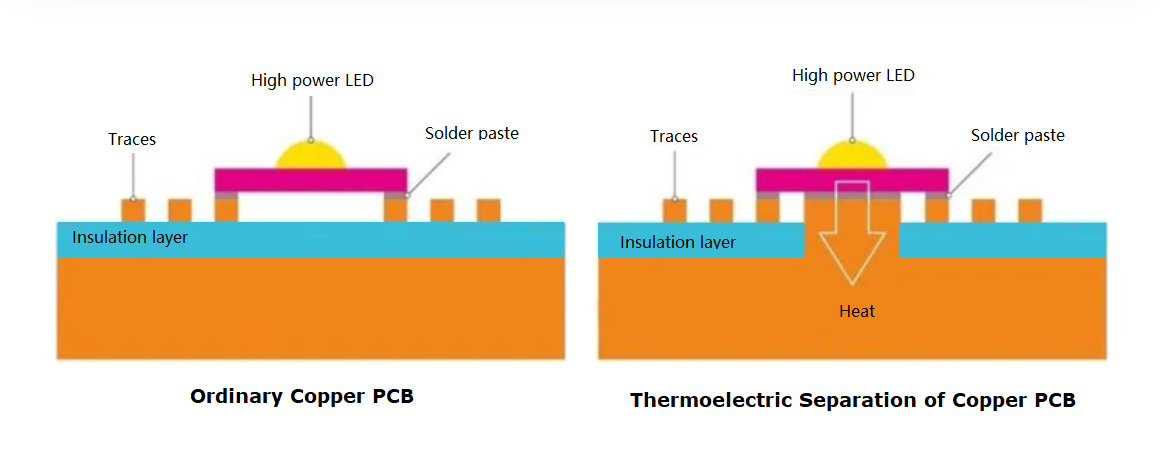

Below is the structure diagram of ordinary copper PCB and copper substrate bump thermoelectric separation as an example to give you a more intuitive understanding of the advantages of thermoelectric separation copper substrate processing technology.

From the ordinary copper PCB diagram on the left, it can be seen that the heat dissipation needs to pass through the insulating and thermally conductive material (purple part in the picture), which is more convenient to process. However, after passing through the insulating and thermally conductive material, the thermal conductivity is not so good. This kind of suitable for low-power LED lights, which is enough.

If the heat dissipation requirements are very large on automotive LED lamp beads or high-frequency PCBs, both normal aluminum PCB and copper core PCB cannot meet the requirements. It is common to use thermoelectric separation of copper substrates. Because the circuit trace and thermal layer are on the different layers, the thermal layer part directly contacts the LED beads (as shown on the right side of the picture above) to achieve the best heat dissipation (zero thermal resistance) effect.

Besides, there are also many various surface treatment options for the thermal electric separation copper PCB, such as OSP, immersion gold, ENIG, immersion silver, silver plating, ENEPIG, etc. It can be carried out according to different needs, and the surface treatment layer and lifespan are reliable.

Who Can Make Thermal-electric Separation Copper PCB for You?

When you are considering to sample or order thermal-electric separation copper PCBs, it is recommended to choose Best Technology. Best team is a professional PCB manufacturer who specializes in PCB manufacturing for over 17 years of experience and provides excellent before and after-sales service. Now, Best Technology highly recommends thermal-electric separation copper PCB for you, and the price is very favorable right now. And we promise that we will make satisfactory thermal-electric separation copper PCB for you with the fastest speed and the highest quality. This is what we are proud of.

If you have any questions or comments about thermal-electric separation copper PCB or more information about our company, please feel free to contact us or e-mail us at sales@bestpcbs.com. We will serve you wholeheartedly.