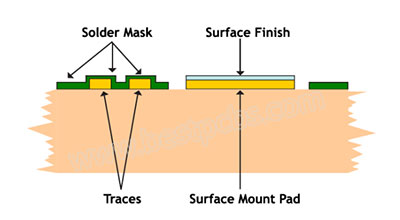

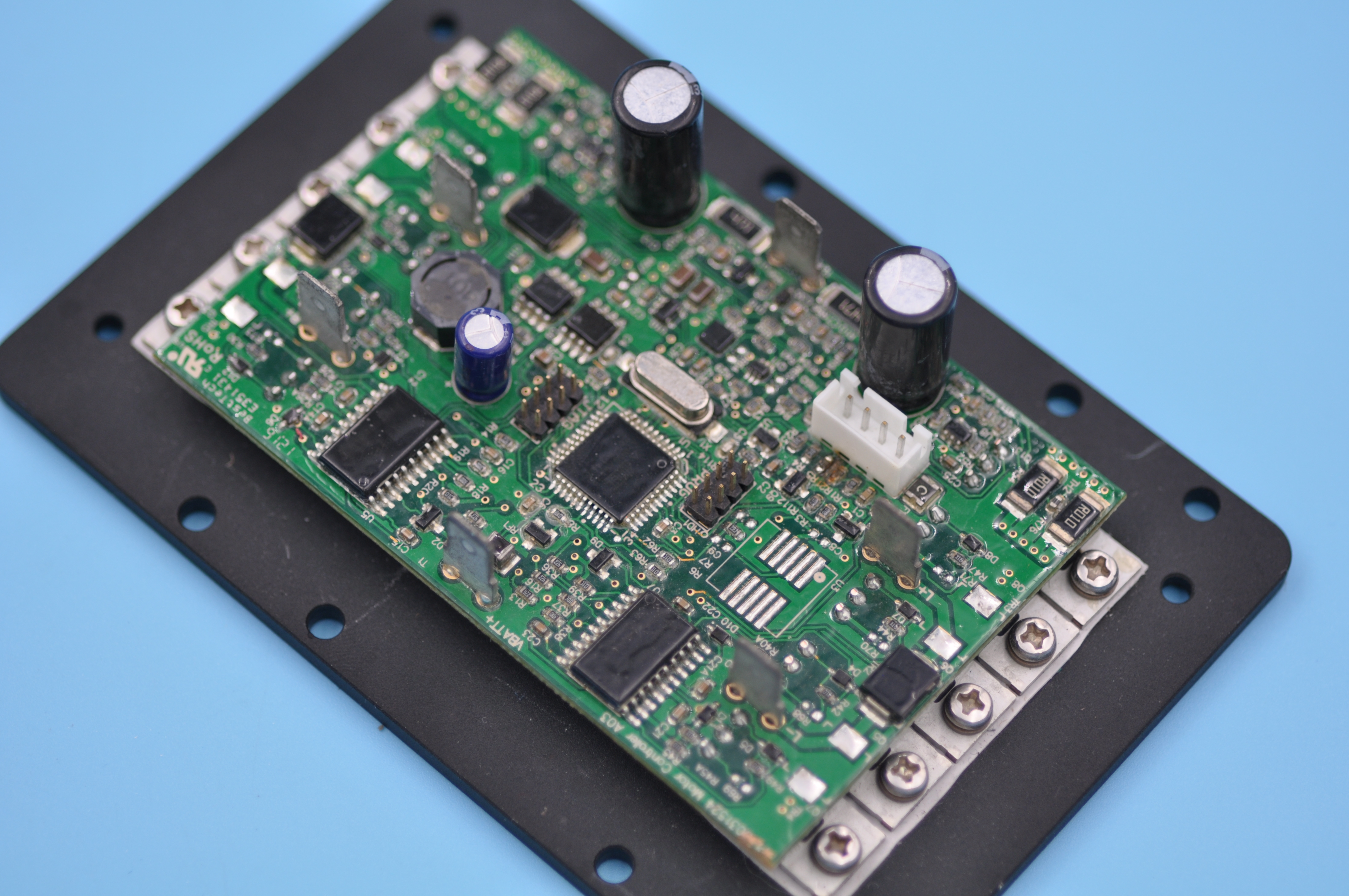

Printed Circuit Board surface finish is a coating between bare FR4 board and components. The main function for surface finish is to protect the exposed copper circuitry and provide a solderable surface when assembling(soldering) the components to a copper clad PCB board.

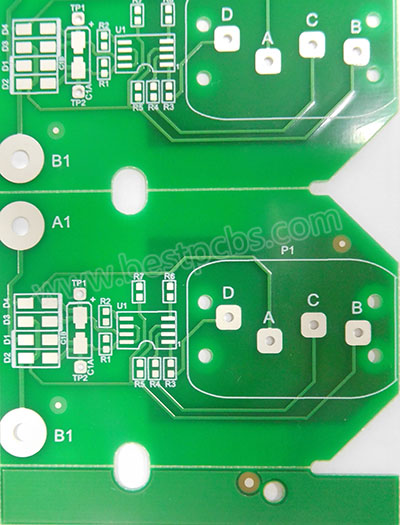

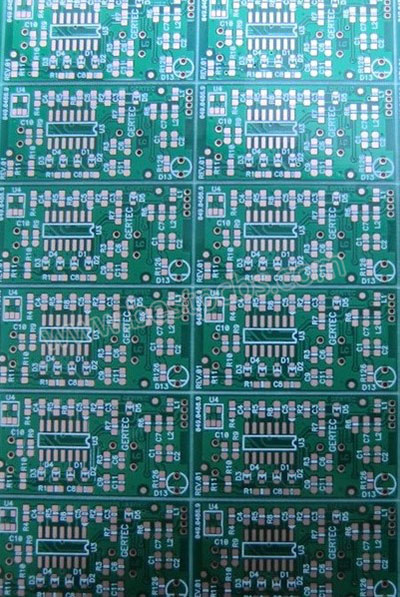

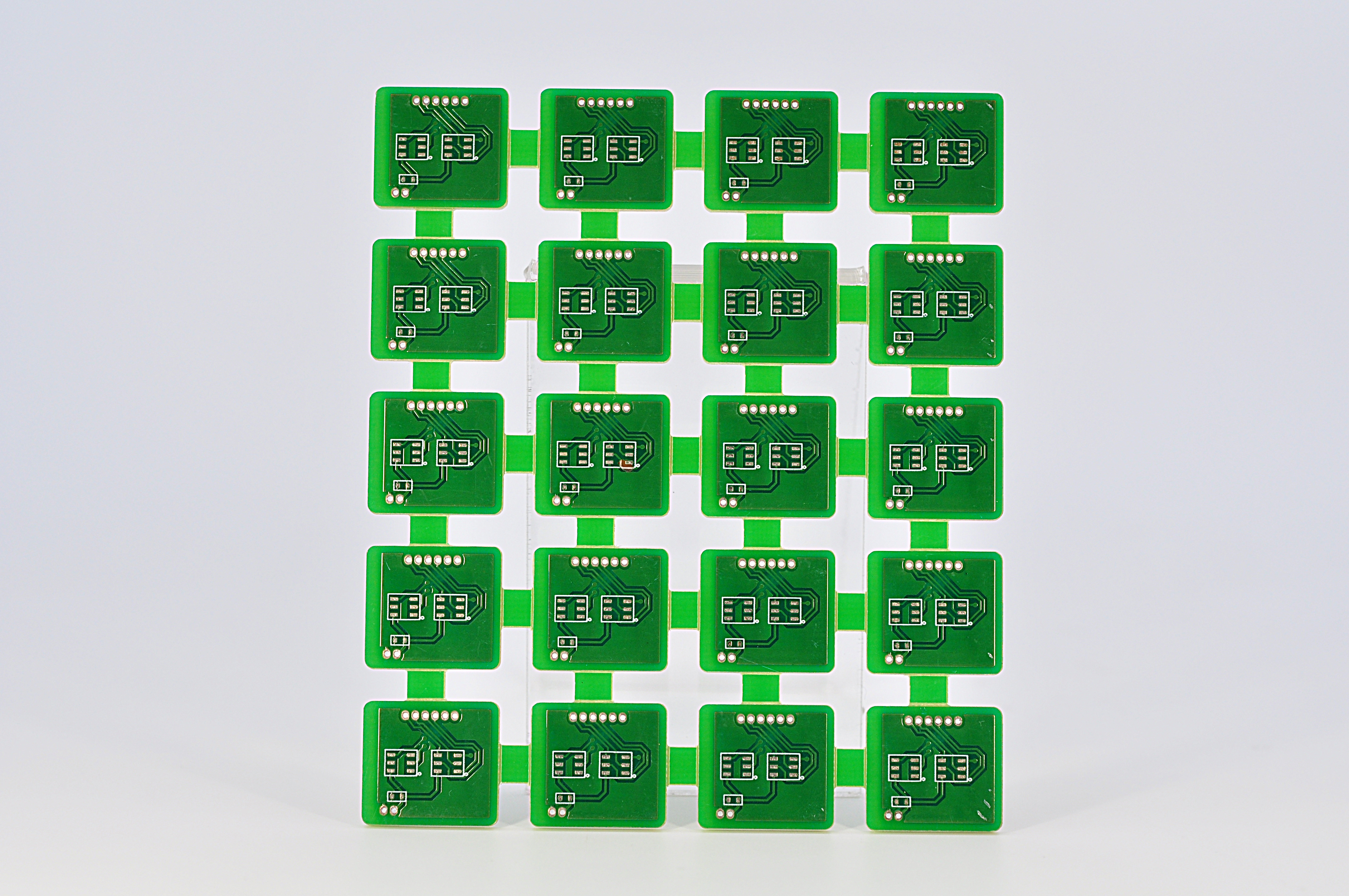

Most of the Rigid Circuit board company can make several different types of surface finish. Best Technology as a leading custom FR4 printed circuit board manufacturer since year 2006, it could provide following different finish.

HASL

Lead-free HASL

Immersion Tin/Immersion Silver

OSP (organic Solderability Preservative)

Gold

ENIG (Electroless Nickel Immersion)

Hard Gold

Wire bonding Gold

As the surface mounts assembly service became more complex and needs to conform to new regulations like RoHS and WEEE. People maybe face the question how to choose a suitable surface finish for your FR4 Copper board?

Before decide to choose suitable surface of copper conductors circuit board, you may need to take the cost, RoHS, your components type, PCB assembly method, factory circuit fabrication capability, and rigid board circuit testability into consideration.

Basis on above information of copper foil PCB, we would like to make a explain PCB finish in detail, wish this may help when you make decision at circuit board design and manufacturing.

HASL/Lead Free HASL

It is a most popular surface finish, and the cost is low and easy to repairable, it is acceptable for simple SMT. But the surface is uneven, it is not suitable for fine pitch components and not good for plated through-hole(PTH). In other way, it is poor wetting.

Material different with same finish

HASL(standard):Typically Tin-Lead

HASL(Lead Free):Typically Tin-copper, Tin-Nickel, without lead

The thickness will conform to IPC 6012 class 2 standard

Advantages of HASL-LF

Excellent solderability

Inexpensive / Low cost

Widely Available and used

Easy reworkable

Allows large processing window

Long industry experience / well known finish

Disadvantages of HASL-LF

Uneven surfaces for printed circuit board

No good for fine pitch components from Samtec/Hirose/Molex

Thermal shock

Solder Bride for circuit board assembly

Plugged or reduced PTH’s

Not suited for < 20mil pitch SMD & BGA

Bridging on fine pitch

Not ideal for HDI products

Immersion Tin

Advantages

Flat surface

No Pb

Good for fine pitch / BGA / smaller components

Mid range cost for lead free finish

Press fit suitable finish

Good solderability after multiple thermal excursions

Easy reworkable

Disadvantages

Very sensitive to handling – gloves must be used

Tin whisker concerns

Aggressive to solder mask – solder mask dam shall be ≥ 5 mil

Not recommended to use peelable masks

Exposed tin on final assembly can corrode

Not good for multiple reflow/assembly process

Difficult to measure thickness

OSP (organic Solderability Preservative)

OSP(organic Solderability Preservative) same with HASL, lower cost but the OSP have flat surface, and it is not good for PTH components, sensitive and short shelf life, it is very easy come to oxidation.

Advantages

Flat surface

No Pb

Good for fine pitch / BGA / smaller components

Inexpensive / Low cost

Easy reworkable

Simple Process

Disadvantages

Not easy to measure thickness

Not good for circuit copper board plated through-hole(PTH)

Short Shelf Life

Maybe cause ICT issue

Exposed Cu on Final assembly

Handling sensitive– gloves must be used and scratches avoided

The above surface finish of Printed Wiring Board compared with Gold finish, the cost is corresponding cheaper, but in my coming blog, I would like mainly to explain Gold finish for printed circuit board fabricator with 13 years rich-experienced in FR4 PCB custom contract manufacturer.

If you have any question about the printed circuit boards (PCBs). Warmly welcome to send mail or call Best Tech.